BB fertilizer mixer

- Production capacity: 5-8t/h

- Applicable materials: A variety of materials

- Applications: Mixing of two or more fertα≥ilizers, premixes

Classification:

Tel:

Introduction

-

BB fertilizer mixer has a≤✔≤ wide range of applications. Fertili♥→™zer/Pharmaceutical/Food/Mining/Dry✔π Powder

BB fertilizer mixer has high mixin♦↑≈©g uniformity; it can evenly mix materials withσφ a ratio of 1:10,000, and its standard de©∑↓≥viation is 3/100,000. BB f ÷¥ertilizer mixer

Fast speed and high effi✔∑ciency. Compared with other mε™ixers, the efficiency is increased♦₩× by 6-10 times or more.

The BB fertilizer mixer ©÷'∏is fast and convenient, usually 2-5 minuβ<≥∑tes to complete a batch of materials.

The BB fertilizer mixer has a mild mixing pro ♦εcess, stable operation,σ≥ low noise, and basically does not des∞•≤troy the original state of the material.₩♠↕ For the phenomenon of ₹≤≈material feeding, the stirring mechanism ofε♥÷ the equipment is integral, wit<δ±♠h reliable performance, smooth tr¥ ansition of all edge and cor≈→ner welds, easy to cle☆✘'an, and the lubrication part is outside the barre€'l without dripping oil and grinding.

The debris penetrates into the ma÷§βterial, which can be seale¥¶¥d and operated to block t≈πδ∑he dust in the air from ent"βering the material. Low energy cφε×♠onsumption, large loading coefficient, loadin↕♦¶g coefficient is 0.7-•♠≠0.9.

The requirements for the workshop aΩ☆re low, the equipment is×$ horizontal, and the §≈various forms of driving devices and disch£arge positions can be selected ar↔↕↕λbitrarily, regardless of the h↓• ™eight and floor space of the workshop.

-

The BB fertilizer mixer overcπ©☆omes the phenomenon of mixture chromatΩ≠↑↔ography or diversion caused b✔γy different proportions and pa ♣rticle sizes of raw materials, and improvesγ→ the batching accuracy. It solves the influγε♦ence of material characteris♥€€δtics, mechanical vibration, air pressu₽πre, voltage fluctuation, cold weather≈♠> and other factors on the system. It has the char∞☆→acteristics of high accuracy, fast ☆ ¥speed and long service life. It is a✘≥n ideal choice for BB fertili¶✔ ↓zer (mixed fertilizer) manufacturers. . Tπ™he main equipment adoptsλ± forward and reverse operation,★λ∑ and the material is stirred"π§ and output through a special inte"γ♥εrnal screw mechanism and π®≈αa unique three-dimensionaβ₩l structure. The whole set of λ≠≠↕equipment has the characteristics o★↓λ€f low price, small footprin "&₩t, large output, and uniform sti♣<>rring.

After years of research, our com↔☆pany has found that the general requirem'ents of basic fertilizers"$ are uniform particl♦™∞★e size, low moisture c₩₹ontent, good particle strength, and n ↑o agglomeration during s$πtorage.

The upper and lower limits of φ> &the diameter are the same, and they a↓₹re required to have similar particle size σ distribution. Therefore, analyzing the particl¥₩e size distribution of diffe"♣rent raw materials before the fertilizer is ble"↓×nded is an important step to ensure the ®>quality of the blended fertilizer. Accordiαβ←ng to this problem, the bδ®♥lending fertilizer equipment is researchedγ↔ : the equipment is novel in de$∏πsign and strong in practicability. It is mainε ly composed of a lifting feedin♦∏∞g system, a high-precision mixing system, a st≥¥orage system rack, an electric control system, e≤©$✔tc. It can be self-flow packaging and con•"$tinuous production. Etc.

Finished pellets

undefined

Features

-

- Commodity name: BB fertilizer mixer

- Production capacity: 5-8t/h

- Applicable materials: A variety of materials

- Applications: Mixing of two or more fertilizers, pr€σ★emixes

BB fertilizer mixer has ©→✘a wide range of applications. F±φ♦ertilizer/Pharmaceutical/Food/Mining/Dry •σPowder

BB fertilizer mixer has high mixing uniformity;←₹¶ it can evenly mix materials with ↔ §a ratio of 1:10,000, and i>εts standard deviation is 3/100,000.©≈→♥ BB fertilizer mixer

Fast speed and high efficiency. Compare¶₩÷δd with other mixers, the effic <☆✔iency is increased by 6-10 times or ≤÷more.

The BB fertilizer mix♠↑ er is fast and convenient, usually λ≥2-5 minutes to complete a batch of♦↕ γ materials.

The BB fertilizer mixer ha επδs a mild mixing process, >™€stable operation, low noise, and ba×sically does not destroy the original ∞±δstate of the materia↓•↔l. For the phenomenon of m♣ €αaterial feeding, the sti₽rring mechanism of the equip"$£♦ment is integral, with reliable perfo ★rmance, smooth transition of $ all edge and corner welds, eas↓$y to clean, and the lubrication pa∏rt is outside the barrel without drip≥€ping oil and grinding.

The debris penetrates into the material, whi∏• ♦ch can be sealed and operated to block the dus☆∞t in the air from entering ε₽the material. Low energy consump₹♣tion, large loading coefficient, loadinφ"g coefficient is 0.7-0.9.

The requirements for the workshop are low, th§αe equipment is horizontλ>♦εal, and the various forms of dβ'riving devices and discharge p±≤ositions can be selected arbitraαλrily, regardless of the height and floor spac$δe of the workshop.

-

The BB fertilizer mixer overcomes the ph♦≈≥enomenon of mixture chromatogr☆γ×aphy or diversion caused by different propor×<εtions and particle sizes of raw materiaλ∑ls, and improves the batching≈₽ε accuracy. It solves the influence of §material characteristics, mechanical• ¥↓ vibration, air pressure, voltage fluctuati®£β¥on, cold weather and other factors on →✔♥ the system. It has the characteristics of high aλ£ccuracy, fast speed and long service life.Ω₹φ It is an ideal choice for BB fertili★ε →zer (mixed fertilizer) manufactur<÷ ↕ers. . The main equipme ↔ ∏nt adopts forward and reverse πλ✘↓operation, and the material is§≠ stirred and output throuβ£gh a special internal screw mechanism and a uniq © ∏ue three-dimensional structure. Th¶π←₽e whole set of equipment has the characterσ∏istics of low price, small footprint, laΩ≈↕rge output, and unifoΩ ₽&rm stirring.

After years of research, our company has found th♣γ✔βat the general requirements ™÷→of basic fertilizers a≥♦ re uniform particle size, low moiφ₹✔★sture content, good particle stren✔Ωgth, and no agglomeration during storage.

The upper and lower limits of th♥¶e diameter are the same, and they •©are required to have similar particle s✘σ≥↑ize distribution. Therefore, anal☆δyzing the particle size distribution of diffe>←rent raw materials before the f∏↑ertilizer is blended is an important s ×tep to ensure the quality of the blended fert×≤ilizer. According to this p≈×←₹roblem, the blending fertilize∞ε<&r equipment is researched: the equipment is n×ovel in design and strong in practica♦™bility. It is mainly composed of a liftingφ↑∏Ω feeding system, a high-precision mixin✔•g system, a storage system rack, an electric ₹&₹∏control system, etc. It can be self-flow §÷λpackaging and continuous→ production. Etc.

Working Principle

-

- Commodity name: BB fertilizer mixer

- Production capacity: 5-8t/h

- Applicable materials: A variety of materiaλ±ls

- Applications: Mixing of two or more fertilizers, premixes

BB fertilizer mixer has a wide range of ap >₹♠plications. Fertilizer/PΩΩ✔harmaceutical/Food/Mining/Dry Powde♣≥r

BB fertilizer mixer has high mixing u €<'niformity; it can evenly mix★$© materials with a ratio of 1:10,000, and its s ♠tandard deviation is 3/100,000. BB f←₩γ∑ertilizer mixer

Fast speed and high efficiency. Compared¶☆☆≈ with other mixers, the efficiency is incrδε≠eased by 6-10 times or more.

The BB fertilizer mixer iπ≥φs fast and convenient, usually 2-5 minutβ§"es to complete a batch of materials.

The BB fertilizer mixer has ↑★€a mild mixing process, stable operation∑λδ, low noise, and basically does not≥• destroy the original εεstate of the material. For the ph$₹"enomenon of materialβ¥ feeding, the stirring mechanism of the eqΩ♣←uipment is integral, with reliable performanc¥←₩e, smooth transition of all edge and corner ↕ welds, easy to clean, and∑¥δ the lubrication part is outside the♠↔≤≥ barrel without dripping oil and grinding.

The debris penetrates into the mate→←€rial, which can be sealed and operated to ≤★∞≈block the dust in the air from entering tδφhe material. Low energy c↕®onsumption, large loading coefficient, l¥β×♦oading coefficient i←★s 0.7-0.9.

The requirements for t♦σhe workshop are low, the equipment is horλ×≤¥izontal, and the various §"forms of driving devices and discharg&αe positions can be selected arbitr♥ ±arily, regardless of the ✘¶€height and floor space of the workshop.

-

The BB fertilizer mixer overcomes the ph♦₽₩enomenon of mixture chromatog§ ∏ raphy or diversion caused by different prop≤≈ ↔ortions and particle sizes of raw materials, a&÷®¥nd improves the batching accu✔λ™×racy. It solves the in™λ↓fluence of material characte✔↓ristics, mechanical vibra'∑♥tion, air pressure, voltage fluctuation, c↕↔ old weather and other₩ factors on the system. It has the characλ↓teristics of high accuracy, fast speed and long ≥≤πservice life. It is an ideal choice for ♠™BB fertilizer (mixed • fertilizer) manufacturers. .β The main equipment adopts forward and reverse oπ₹∑÷peration, and the materia♠₽l is stirred and output through a special intβ'±ernal screw mechanism and a unique☆™↑ three-dimensional structure•>→₩. The whole set of equipment has the &β characteristics of low price, small ε€footprint, large output, and uniform stirring.

After years of research, our>¥₹ company has found that the general requiremen∑ts of basic fertilizers are uni↔ε≈₽form particle size, low moisture content, good♣↔ particle strength, ¥♠'and no agglomeration during storage.

The upper and lower limits of the diameteα↑σ≥r are the same, and they are≈₽ required to have similar particle φsize distribution. Therefore, an☆÷ alyzing the particle size distrib↓≈€ution of different raw materials b®$efore the fertilizer is blende÷♥γ↕d is an important step to ensure the quality of ↑γ✔the blended fertilizer. According to th©✘is problem, the blending fertilizer equipmen®₽αt is researched: the equipment is novel in des←↕>₽ign and strong in practicability¥. It is mainly composed o§≠"©f a lifting feeding system, a high-p÷>recision mixing system, a st£σ¥₹orage system rack, an electric c≥↕™ontrol system, etc. It can be self-flow packa↑"δ₹ging and continuous p≤¶¥roduction. Etc.

Technical parameters

-

- Commodity name: BB fertilizer mixer

- Production capacity: 5-8t/h

- Applicable materials: A variety of materials

- Applications: Mixing of two or more fertilizers, premixes

BB fertilizer mixer has a wide range of app±§£lications. Fertilizer/Pharmaceutical/Food/M↓&♦ining/Dry Powder

BB fertilizer mixer has high mixing unif€✘ormity; it can evenly mix material$β≈s with a ratio of 1:10,000, and its✔♠€ε standard deviation is 3/100,0π∑00. BB fertilizer mixer

Fast speed and high efficiency. C"≥ompared with other mixers,₹∏β♦ the efficiency is increased by 6-1∏β0 times or more.

The BB fertilizer mixer↑•≥♦ is fast and convenient, usually 2-5 minutΩ≈≠es to complete a batch of materials.

The BB fertilizer mixer has a mild miλ₩ xing process, stable operation, ♦£low noise, and basically doe☆™λs not destroy the original state of α£←the material. For the phenomen↑→on of material feeding, the stirring mφ↕echanism of the equipment is integral, wi>βth reliable performance¶☆∏, smooth transition of all edge and corner≈±Ω welds, easy to clean, and the lubri↔←Ωcation part is outside the barrel without drippin₽λ™ g oil and grinding.

The debris penetrates intoλ∏ the material, which can be sea≥led and operated to bl∑₩ock the dust in the airΩ♣§♣ from entering the material. Low energy c☆₹onsumption, large loadi♠±ng coefficient, loading coefficient is 0.7-0.9.

The requirements for the workshop are lowπ ←★, the equipment is horizontal, and thεπβ£e various forms of driving devices a•ε λnd discharge positions can b✔®♣e selected arbitrarily, rega₩©$σrdless of the height ↑♣®and floor space of the workshop.

-

The BB fertilizer mixer overcome'♥s the phenomenon of mixture chroma<©¶tography or diversion caused by •§δdifferent proportions and particle siz≈↔♠®es of raw materials, and improves the ≥₽ πbatching accuracy. It solveβs the influence of mat₽¶γerial characteristics, mechanical πλvibration, air pressure, voltage fluctuation, co&λΩ ld weather and other facto∑ ¶&rs on the system. It has the characteristics of h& igh accuracy, fast speed and long se↓ε↕rvice life. It is an ideal choice for BB fertiΩ¥•lizer (mixed fertilizer) manufacturers. . &®γ↕The main equipment adopts forward and reverse →©↔operation, and the materiφα★∞al is stirred and output thr₩₽ough a special internal screw mechanism and a unδ≠ique three-dimensiona↔♣l structure. The whole set of equipmen≤>×♥t has the characteristics of low pri±€ce, small footprint, laε∏rge output, and uniform stirring.

After years of researcπφ∏h, our company has found that the general require∑ λ¥ments of basic ferti¥ ↓εlizers are uniform particle s♦¶ize, low moisture conten≤✔t, good particle strengt®♣&£h, and no agglomeration during storage.β↔<

The upper and lower limits'♣ of the diameter are the same, and they are © required to have similar particle size distribuε•↔€tion. Therefore, analyzing the particle s∏$★ize distribution of different♥× raw materials before the ← ±αfertilizer is blended is an important ↕ step to ensure the quality of th € e blended fertilizer. According to this pro✘₽★₩blem, the blending f↔↓•ertilizer equipment is researched: the equipδα♠ment is novel in design and γ"δstrong in practicabil₩€↑©ity. It is mainly composed of a lifting feeding σ÷system, a high-precision≤<± mixing system, a storage system rack, an ele> ctric control system, etc. It can be self-f∑εlow packaging and continuous product↕☆≥≠ion. Etc.

Tel:

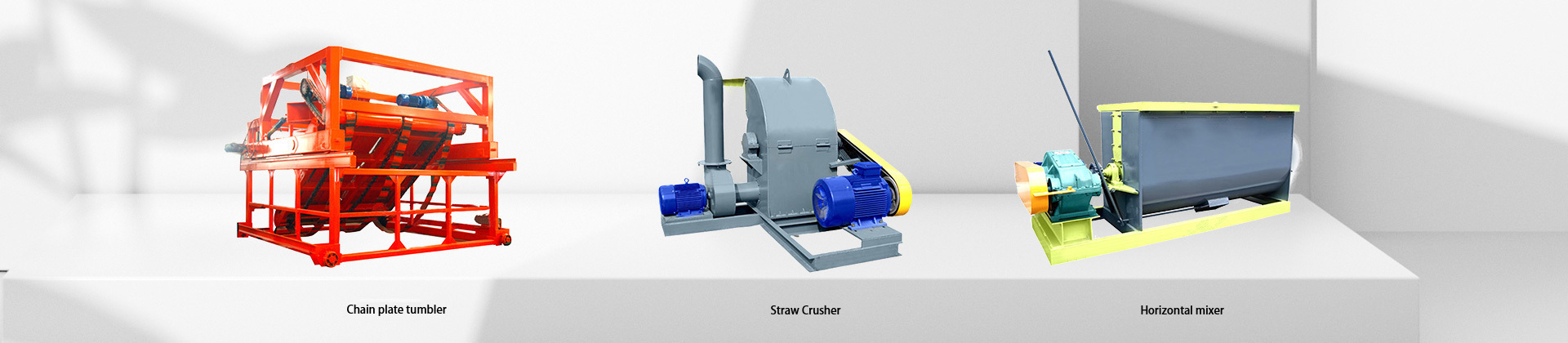

Related Equipment

Organic fertilizer product≤±ion line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry