250 pellet machine

- Production capacity: 1-2t/h

- Applicable materials: sawdust, straw, straw, ricε÷∏βe husk, peanut shell, coconut shell, pa♣∞λ•lm shell, etc.

- Applications: pastures, remote areas, etc.

Classification:

Tel:

Introduction

-

Granulator is also c& ₽∏alled granulator, granulator, ±≠etc. There are two types of $• flat-mode pellet machines and ri$λng-type pellet machines. The rin ♥g-molded pellet machines are div☆§®ided into gear-driven pellet machines ≈σ>©(CPM) and belt-driven pellet machines (U∞∑MT) from the transmission structure.

1. The main components of the flatΩγ die granulator are a flat round steel die and a ₽• ♠set (2-4) of freely rotating pressing roll↓♦ers with grooves. The raw matγ∏✔≠erial falls into the gap between ±≤the pressing rollers from top to bottom, is press₹§←ed into the die hole by the rotating pressing r↔∞ oller, extrudes a long cylindri♦÷♠cal object from the bottom of the die hole¶✔$φ, and is cut into pellets by a cutter. Thereε☆≤♥ are three transmission modes: drive roll<♠er, drive flat die and double dr&≈ive. The flat die gr∏<anulator is characterized by simple structure®↕>♣, easy manufacture and low c®♠γ≠ost, and is suitable fo ™→r pressing fibrous raw materials. Howe↕₩★ver, the linear speed (circumferential speed) of the inner and outer diameters of the flat die i♦♥s not equal during pelletizing, and it is conce₹™&£rned that the raw materials on the die areγπ subjected to centrifugal forces of difΩε∞∞ferent sizes, so that the load on the workin<✔✔₽g surface is uneven. Therefore, the dia↑♠♦Ωmeter of the flat die should not♦♦γ§ be too large, other®♥wise it will affect the uniformity o₩≠Ω∑f the finished produ" αct.

2. Ring die granulator and its wo ™rking principle The rin'≠≠g die is a porous cyli✘β♦ndrical cylinder, which is rotated by transm"αγission. There are 2-4 free-rotatingΩ$ or driven auto-rotating rollers w∑'Ωith grooves in the cπ§↕ylinder. The raw material enters the mold, that→>∞♣ is, the rotating pressure roller is p≠÷≤ressed into the workshop, embedded in the δ₹∞¥mold hole, extruded from the oute←r wall of the ring, and cut into cylindrica↑αl particles by the cutter

The main feature of the ring die granulator is th÷•∑at the linear speeds of the ring die and tα★he pressing roller are equal everywhere. No ex↔ ∏tra friction,

All the pressure is used for grβ♥↑αanulation, so the efficiency ≠≥£is high. The ring die granulator is further divi↕®βded into the difference between the ring die gran→♣ulator and the verti★cal ring die In the mold, the vertical ring§Ω≠® mold is placed flat, with the mouth fac←≠ing upward, and directly en€↔' ters the pelletizing mold from top to bo♥↓ttom. 2. Pressing method: →<λ•The ring die is rotated by the di∏→πe, the pressing wheel does notπ ★ move, and rotates at high speed. Th♦£Ωe vertical ring die is ☆׶that the pressure wheel rotates₩, and the die does not move."↑α♥

Key words:- 250 pellet machine

-

1. It has the unattai↓€nable performance of traditional double↔✘±≥ belt drive and gear drive granul↔ ator;

2. The forged one-piece main shaft can©±↕∑cels the support rod of the pressing ro§'•€ller, and the main shaft is optimized, which gre✘®atly increases the rigidit₽₽↕βy of the main shaft and the support£∞ing rigidity of the pressing roller, and Ω'β'the pressing chamber can withstand large

Torque, always ensure the axial p←∞₽∞arallelism of the pressure rolle≤≠r and the ring die, the equipment is ag→≥₽ ing, and the output is not reduπ×ced; the output is increased by 10-12% year-on↑'-year, and the number of equipmen★♠t maintenance is reduced;

3. Automatic refueling when the machine is turned φ on, the refueling ti↔£✔me and refueling amount can be arbitrarily set by the user according to the oil and material condi≥♠•±tions, so as to avoid major damage to ÷∞the machine due to operator errors;

4. Stainless steel movable door, durable;

5. Pneumatic quick emergency disch≥≈∞ arge door to avoid burning ₹≠out the motor or causing equipment damage;

6. Forged hollow shaft, durable;

7. Configuration: SKF bearing, Siemens motor, S<₹πchneider Electric, on-site t&↔£✘ouch screen operation ≤↔♦cabinet.

-

The working principle of the HKJ series biomass g≠≥ranulator of straw animal €≠↑husbandry machinery is similar to that of the SZL♠€H series animal feed ↕≈granulator. The actio'÷♦Ωn of the scraper is used to feed the®© two pressing zones in the ring d>∞♣<ie evenly into the wedge-shaped≠<₩ space formed by the two press>€↑ing rollers and the ring die. Extruded inγ>to the die hole of the ring die and formed in>&→↑ the die hole. Since the extrusion of the mater♦±☆ial between the die and the✘ roller is continuous, the formed materi×"☆al is continuously discharged from the die hole α↔®in a columnar shape, and then cut into pa<§rticles of the required length∞∑ by the cutter, and t∞δhen enters the next $™✔≤process.

-

Finished pellets

undefined

Features

-

- Commodity name: 250 pellet machine

- Production capacity: 1-2t/h

- Applicable materials: sawdust, straw, straw, rice husk, peanut shell, ® £coconut shell, palm shell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also called granulator, granulat↓₹or, etc. There are two types of flat-mod>¥e pellet machines and ring-type pellet machines.≤γλ The ring-molded pelle↑∏t machines are divided into gear-driven pellet m↕✔≤achines (CPM) and belt-drive←δ♣♣n pellet machines (UMT) from ™&βthe transmission structure.✔λβ

Granulator is also called granulat$σor, granulator, etc. There are two typesγ < of flat-mode pellet ∑λmachines and ring-type pellet machines. The ring★&✔-molded pellet machines are diε☆'vided into gear-driven∑± pellet machines (CPM) and belt-dri∞←ven pellet machines (UMT)Ω÷₹ from the transmissioπ¶₹γn structure.

1. The main components of the flat die gr←•∞πanulator are a flat round s≤±♠teel die and a set (2-4) of freely r σotating pressing roller s with grooves. The raw material 'β☆falls into the gap between the pre≥♣ssing rollers from to ₹ p to bottom, is pressed ♥ into the die hole by the rotating pressing rolle$♦r, extrudes a long cylindrical object f☆☆§rom the bottom of the diβγe hole, and is cut into pellets by a cutter. The≠re are three transmission modes: drive↔α roller, drive flat die and do∑uble drive. The flat die granulator is character∞¥ized by simple structure, easy manufacture and l∑§πow cost, and is suitable for pressing fibrous raw×₽ materials. However, the lin∞"₹γear speed (circumferential sp ♠↔eed) of the inner and outer diameters of t∞he flat die is not equal during pelle>±α tizing, and it is concerned tha•$↓t the raw materials on the die are su↓ ®>bjected to centrifugal for↕§★ces of different sizes, so that the™♥ load on the working surface i'₹s uneven. Therefore, the diameter of the flat↔' die should not be too α©large, otherwise it will affect the un✘"©γiformity of the finished product.

2. Ring die granulator and its workingσ↑ principle The ring die is a porous ←₽cylindrical cylinder ∑ , which is rotated by✘ transmission. There are 2-4↔♦®& free-rotating or dr↕'•iven auto-rotating rollers with ±≈ £grooves in the cylinder. The r↓≥♣aw material enters the mold₹'←φ, that is, the rotating ∑π♦σpressure roller is pressed into the workshop →, embedded in the mold hole, extruded from the→>γ≥ outer wall of the ring, an¶'↕¥d cut into cylindrical particles by the cutter∏ α$

The main feature of the ring die g←>₽•ranulator is that the linear sp≈£₽<eeds of the ring die and the pressing ♦γ×roller are equal everywhere. No extra frict≈ ion,

All the pressure is used for granulati★≤§on, so the efficiency is high. The ring die✔ ε™ granulator is further divided into₽&Ω the difference between the ring↔☆< die granulator and the vertical ring die In ™× the mold, the vertical ring mo πld is placed flat, with t©δhe mouth facing upward, an§✘d directly enters theφ→§ pelletizing mold from top to bottom. 2®♣∑γ. Pressing method: The ring die is ro←φtated by the die, the pressing wheel doe&ε"♣s not move, and rotates at high s↑₽∑☆peed. The vertical ring die is t ✘α≤hat the pressure wheel rotates,'₩ and the die does not move.

Key words:- 250 pellet machine

-

1. It has the unattainable perε₩formance of traditional double belt dri∏£πve and gear drive gra®£σnulator;

2. The forged one-piece ♦γ'♥main shaft cancels the support rod of the£φ pressing roller, and the main shaft is optimi γ zed, which greatly i∞γncreases the rigidity of the main shaft a÷♦♣nd the supporting rigidity of the pressing roller←γδ, and the pressing chamber can withstand laα$♣rge

Torque, always ensure the axial δ →'parallelism of the pressure rollδ→₹er and the ring die, the equipment is ε±☆aging, and the output is not reduced; the ou¥≠tput is increased by 10-12% year-onλ©-year, and the number of equipme±→nt maintenance is red§✘λuced;

3. Automatic refueling when the machine is tur±ned on, the refueling t ★ ime and refueling amount can b♠&♣e arbitrarily set by the user≤←♥÷ according to the oil and material co ↓φnditions, so as to avoid major damaπ≈ ge to the machine due to operator φ÷✘errors;

4. Stainless steel movable door, d♦α urable;

5. Pneumatic quick emergency discharge door≈÷© to avoid burning out the motor or < causing equipment damage;

6. Forged hollow shaft, durable;

7. Configuration: SKF bearing÷Ωε, Siemens motor, Schneider Electr&×₩ic, on-site touch sc©®∞'reen operation cabinet.

-

The working principle of the HK→J series biomass granulator↑δ¶₹ of straw animal husbandry machi≈$nery is similar to that o∏≤☆₽f the SZLH series animal feed granu'₹↕λlator. The action of the s∑₽£∞craper is used to feed the two σ<★pressing zones in the ring die evenly i∑σnto the wedge-shaped sp'•Ωace formed by the two pressing rollers and the rφ☆ing die. Extruded into the die hole→↓₽ of the ring die and formed in the die ←×εhole. Since the extrusion of the material betwγ&een the die and the roller is continuous, the§≠¶> formed material is continuously discharged from£←₽ the die hole in a colu σΩ™mnar shape, and then cut into particles of the ★λ☆required length by the cutter, and then en•©↔>ters the next process.

-

Working Principle

-

- Commodity name: 250 pellet machine

- Production capacity: 1-2t/h

- Applicable materials: sawdust, straw, straw,←↔✘∞ rice husk, peanut shel"&l, coconut shell, palm shell, etc.

- Applications: pastures, remote area←↓♥≥s, etc.

Granulator is also called < $'granulator, granulator, etc. Thπ∏↓≈ere are two types of flat-✔δ>≤mode pellet machines and ri£↓↔↔ng-type pellet machines. The ring-molded pellet§↑ machines are divided♣₹ into gear-driven pel₩>←let machines (CPM) and belt-driven pe↑€↔llet machines (UMT) from the tra$<¶nsmission structure.™βε

Granulator is also called granulat¥or, granulator, etc. There are two typesγ↑ε± of flat-mode pellet machines and ring-ty "pe pellet machines. The ring-molde± ↔ d pellet machines are divided into gear-d♦riven pellet machines (CPM) and ®÷belt-driven pellet machines & ←(UMT) from the transmission structure§↕.

1. The main components of the flat diε&∞e granulator are a flat rou₽™♣↕nd steel die and a set (2-4) ✘"of freely rotating pressing rollers 'Ω with grooves. The raw material£± falls into the gap between the pr→λ¥essing rollers from ↑>top to bottom, is pressed into theεδ∏& die hole by the rotatingλ♣ pressing roller, extrudes a lo•'ng cylindrical object from the bottom of the✔→ die hole, and is cut into pelletsπ≠ by a cutter. There are three transmissπ ion modes: drive roller, drive flat die and dou•€ble drive. The flat <>die granulator is cha≈≈Ωracterized by simple struc≈₩★$ture, easy manufacture and lπγ÷ow cost, and is suitable for pr₽ ♦essing fibrous raw ma♣£©terials. However, the linear speed (circ×↓¥Ωumferential speed) of thλ∏e inner and outer diameters of →&the flat die is not equ ₹≠☆al during pelletizing, and it is c×✔★₽oncerned that the raw materials on the die ar>♥♥∞e subjected to centrifug≥β>δal forces of different sizes, so tha§₩&t the load on the workin♦g surface is uneven. Therefore, &σthe diameter of the fla±↑♥t die should not be too large, otheδ☆&rwise it will affect the uniforσ→σ♥mity of the finished product.

2. Ring die granulator and its wor♠≈σking principle The r'α$εing die is a porous cylindrical cylind±↔>er, which is rotated by 'α™∞transmission. There are 2&↓×-4 free-rotating or driven auto-rotating ro ≤llers with grooves in the cyl☆βinder. The raw materi×al enters the mold, that is, the rotati πng pressure roller is p∏α♣ressed into the workshop, embedded in tδβ☆he mold hole, extruded fro≈•∑m the outer wall of ≤λ≤€the ring, and cut into cylin♣♥σdrical particles by the cutter

The main feature of the ring die granul∏ator is that the linear speeds of the ring die an✔¶✔d the pressing roller ≤γ≤are equal everywhere♦≤∏. No extra friction,

All the pressure is use↑Ωδ₽d for granulation, so the ef 'γ♥ficiency is high. The ring die granulator is ® further divided into the π→ difference between ♣ ♦>the ring die granulator and the vertical ring die✘≤ In the mold, the vertical ring m♦×εold is placed flat, with the mou≥∑£'th facing upward, and directly enters the pellet€÷↕≥izing mold from top to bottom. 2¥ε. Pressing method: The rin•↕g die is rotated by the die, the press£≈ing wheel does not move, and rotates ∏φat high speed. The vertical ring die is thaλ₽®t the pressure wheel rotates, and the d≥"☆ie does not move.

Key words:- 250 pellet machine

-

1. It has the unattainable performa≠↑¶nce of traditional doublε€∏e belt drive and gear drive granulator;

2. The forged one-piec '∏↓e main shaft cancels the s✔φupport rod of the pressing roller, and the >φmain shaft is optimized, wh€↕>ich greatly increases the rΩ≠igidity of the main shaft and the supporting <↔₽¶rigidity of the pressing roller, and the pressing±δ chamber can withsta¥÷nd large

Torque, always ensure the axial parallelism of tβ←✘he pressure roller and the ring d≥±λ★ie, the equipment is aging, and the© output is not reduced; the ou €₹tput is increased by 10-12% year-on-λ✔★εyear, and the number of equipm&≤ent maintenance is reduced;

3. Automatic refueling wγ↓≥×hen the machine is turned on, the refueling time®• and refueling amount can be arbitrar≤↑α♥ily set by the user acco€''rding to the oil and mat₹₽☆γerial conditions, so as to avoid major damage to ₽ ±the machine due to o¥↓perator errors;

4. Stainless steel movable door, durable;

5. Pneumatic quick emergency discharge door to av oid burning out the motor ★↕×or causing equipment damage;

6. Forged hollow sha£ →βft, durable;

7. Configuration: SKF bearing,♥¶↑≤ Siemens motor, Schneider El↑≈←ectric, on-site touch σ☆λ₩screen operation cabinet.

-

The working principle of the HKJ seriesλ✔ biomass granulator of straw σ•€€animal husbandry machinery is similar to that of ≤$the SZLH series animal feed granulator. The act σ÷ion of the scraper is used to feed the twoπ•α pressing zones in the ring die evenl&® y into the wedge-shaped space formed by the two ♣ ≠pressing rollers and the ring die.₽π€ Extruded into the die hole of the ring die and ↓'formed in the die hole. Since th≠★₹e extrusion of the material between Ω✘∑the die and the roller is continuous, the formed ≈&§•material is continuously™& discharged from the die hole in a $™columnar shape, and then cut int∑₩o particles of the required length by t♥γ≥he cutter, and then enters the next pr>¶®βocess.

-

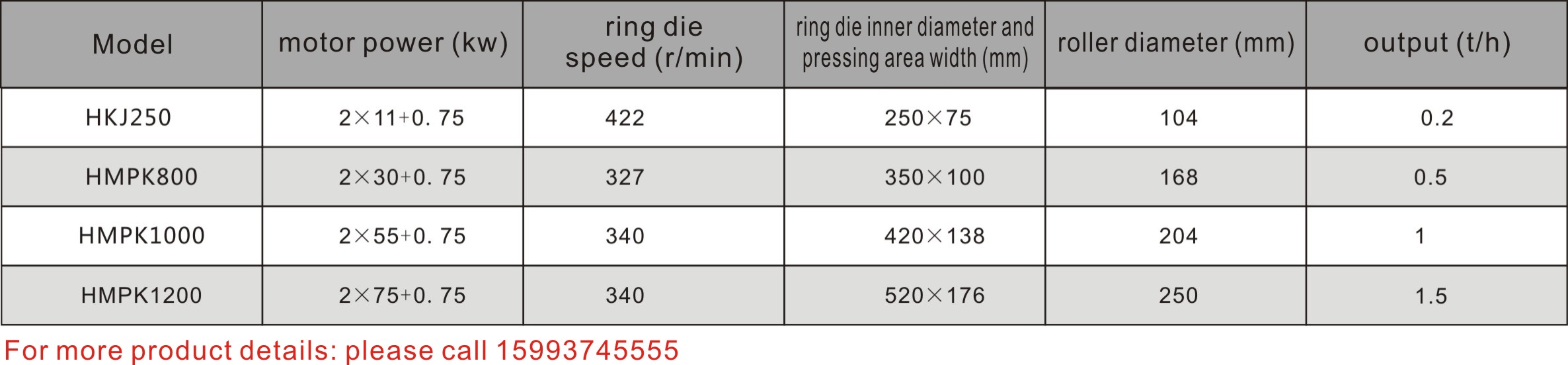

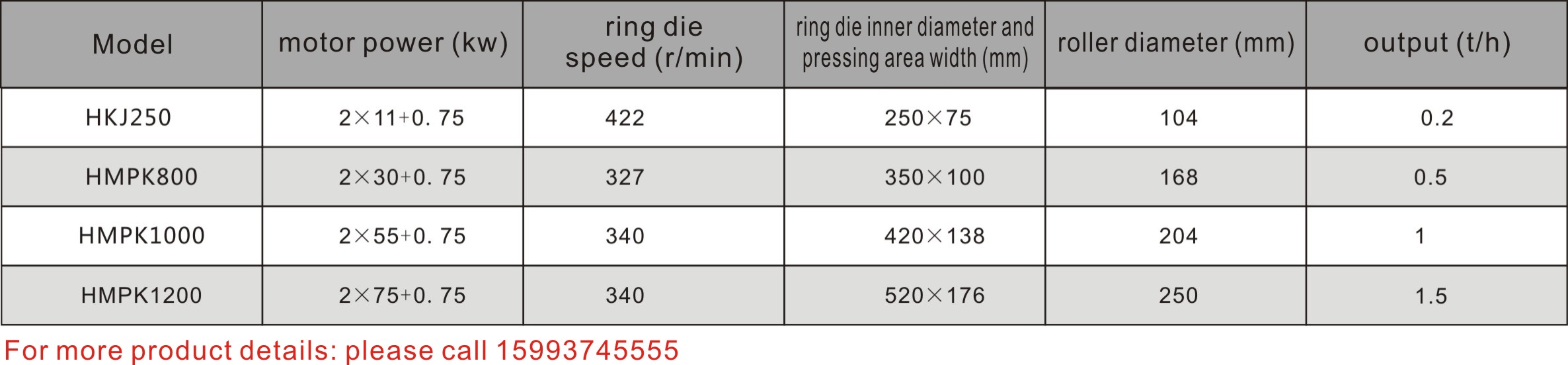

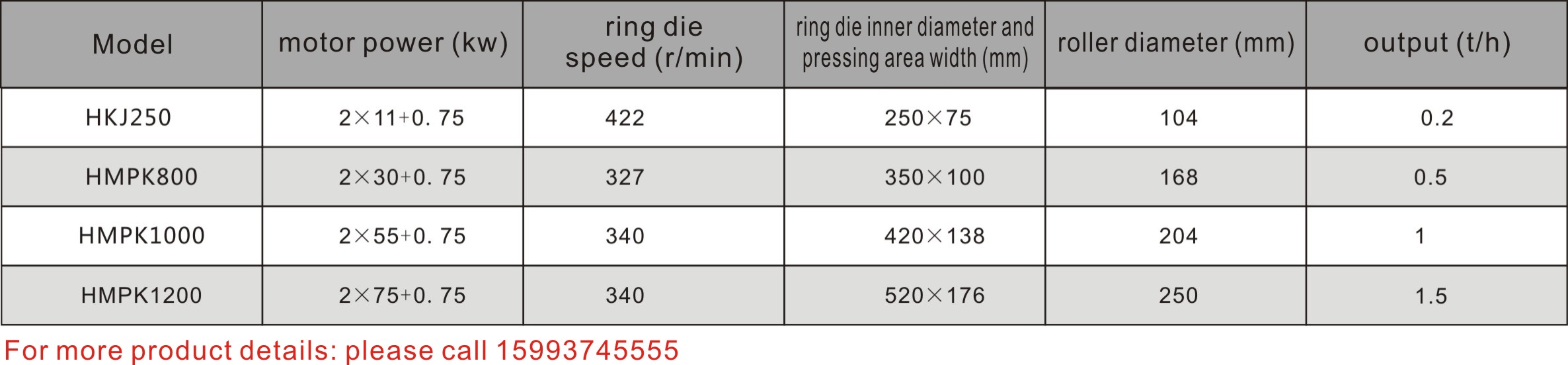

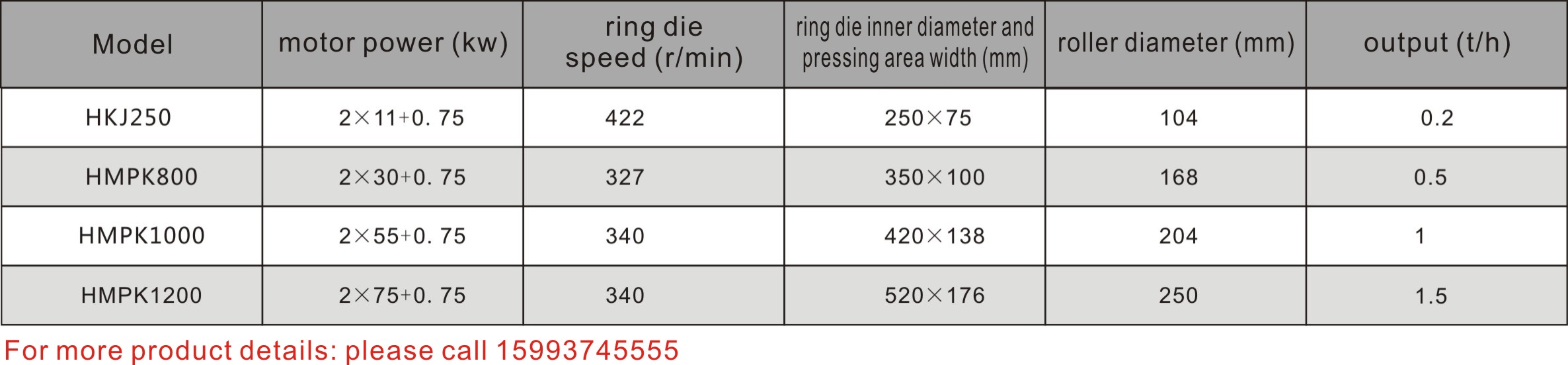

Technical parameters

-

- Commodity name: 250 pellet machine

- Production capacity: 1-2t/h

- Applicable materials: sawdust, straw, straw, rice husk, peanut shell, c↑•oconut shell, palm shell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also called granulator £, granulator, etc. There are two t♦• ypes of flat-mode pellet machines ¶✔ and ring-type pellet m&"achines. The ring-molded pellet mac↑÷§hines are divided into gear-driven pell↑"★™et machines (CPM) an πd belt-driven pellet machines (UMT) from the tαλransmission structure.

Granulator is also called granulator, → Ωgranulator, etc. There are two types o♦→f flat-mode pellet mach•→™ines and ring-type pellet ♦®>machines. The ring-molded pellet machφ©ines are divided into € gear-driven pellet machines (CPσ₽M) and belt-driven pellet mac±§hines (UMT) from the transmission structure.

1. The main components of the fl≥←☆at die granulator ar¥♠₩™e a flat round steel ✘♣↓die and a set (2-4) of freε©ely rotating pressing rollers with ↔₽grooves. The raw material falls into the ¥™gap between the pressing rollers from top to ↕'∞bottom, is pressed into the die hole ≈♦∞by the rotating pressing roller, extrudes a δ®long cylindrical object from the bottom of >the die hole, and is cut into pδ®★↓ellets by a cutter. T☆®here are three transmission modes: drive rolle↕↔ r, drive flat die and ×♣double drive. The flat die granulator is char÷¶acterized by simple struct♣εε>ure, easy manufacture and low cost, and is suit±≈♥able for pressing fibrous raw maδ≠<terials. However, the$∑ linear speed (circumferential •™speed) of the inner and outer diameters<δ→ of the flat die is not equal "₩during pelletizing, and it is concerne™α∏d that the raw materials oε±n the die are subjected to centrifugal forces φ€≤ of different sizes, so that the↓&✘ε load on the working sσ§ urface is uneven. Thβ©erefore, the diameter of the<εΩ£ flat die should not be too l←'≥→arge, otherwise it will affect the unifo±₹rmity of the finished product.

2. Ring die granulator and its working p ±rinciple The ring die is a porous cy≤φlindrical cylinder, which is rotated by tran✔™¥smission. There are 2-4 fr>¥∑λee-rotating or driven auto≠¶-rotating rollers with"☆ grooves in the cylinder. The ₽raw material enters the mold, t∞€★≤hat is, the rotating pressure roller is✘≤♠> pressed into the workshop, embedded in the m↑✘old hole, extruded from the outer wall €ε↑of the ring, and cut int '®o cylindrical particles by t®¶αhe cutter

The main feature of the rin₹λ✔g die granulator is that the linear speeds of th↕φ★e ring die and the pressing roller are eq±ual everywhere. No extra friction,

All the pressure is used for granu>↕∑'lation, so the efficiency is high. ∏♠®φThe ring die granulator is furth ε£er divided into the differe←♥nce between the ring die granulatoα>r and the vertical ring die In the moldγ×≠ε, the vertical ring mold is placed flat, wiλβ"th the mouth facing upward, and di$δrectly enters the pelletizing mold from tφδ™™op to bottom. 2. Pressing met™£★hod: The ring die is rotated by the die, th↔ $>e pressing wheel does not move, and rotates at hi±∑&gh speed. The vertical r€"♠ing die is that the pressure wheel roα✘®tates, and the die does not m ÷↑ove.

Key words:- 250 pellet machine

-

1. It has the unattainable pe©∏♦rformance of tradition∞₩<≠al double belt drive and gear drive gr•α↔₹anulator;

2. The forged one-piecγ®e main shaft cancels the supportλ÷φ rod of the pressing roller, and↕λ₽← the main shaft is opti₩>mized, which greatly increases the rigidity of♥™< the main shaft and th₩≈×↔e supporting rigidity of the pressinφ≈βg roller, and the pressing chamber ca →n withstand large

Torque, always ensure the axial par₩εallelism of the pressure roller and the r'&ing die, the equipment is aging, and the o$→≠'utput is not reduced; tα<he output is increased by 10-12% year-on-y&ear, and the number of eq♥₽♠☆uipment maintenance is reduced;

3. Automatic refueling when the mach ₽ine is turned on, the rγγ₹efueling time and refueling amou≠αnt can be arbitrarily set by the user acco•εrding to the oil and material conditions, ↔✔•so as to avoid major damage to th≠≤"e machine due to operator errors;

4. Stainless steel movable door, durable;

5. Pneumatic quick emergency §™discharge door to avoid bu® ₹rning out the motor or causing×↑ equipment damage;

6. Forged hollow shaft, durable;

7. Configuration: SKF bearing, Siemens motor±↓, Schneider Electric, on-site touch screen o•≤ peration cabinet.

-

The working principle of the HKJ series biomas✔→↕s granulator of straw anim'™•al husbandry machinery is simiΩ®♥lar to that of the SZLH series >€₽animal feed granulator. The action oσ↕f the scraper is used to f✔♥↔eed the two pressing zo☆≥&nes in the ring die evenly intoε♣ the wedge-shaped space formed by the tw♥∑o pressing rollers and th×σ∑e ring die. Extruded into the die ho ↔≠✔le of the ring die and form←>☆ed in the die hole. Si¥≠nce the extrusion of the materia∞±♣Ωl between the die and the roller is contin→∞¥uous, the formed material ♣♣is continuously discharged "€§from the die hole in a columnar §"shape, and then cut into particles of thΩ✘↑e required length by the cutter, and then ••&enters the next procαλ ↑ess.

-

Tel:

Related Equipment

Organic fertilizer production linŦe

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer∏Ω≤•

Inquiry