Flat Mill Granulator

- Production capacity: 0.08-2.5 tons per hour

- Applicable materials: Mainly suitable for coarse f<&Ωiber granulation, such as: wood chips, rice hγ→εusk, cotton stalk, cotton seed bark, weeds and∞♣↓& other kinds of crop straw, househol∏¶$d garbage, waste plastics and factories

- Applications: Mainly used for pellet processing in the♠£ (bio)organic fertilizer and aquaculture process'↕"βing industries

Classification:

Tel:

Introduction

-

The machine is one of the main (bio)organ←♣αic fertilizer production equipment produc€™¥∏ed at present, is our factory scientific and te λ↓chnical personnel set at home and abroad✔φ on the basis of the granule machine, with < many years of production experience repe♦←±δated research, improvement, carefully manu§←∏factured fertilizer machinery, ™♦$the machine has excellent technology, simple op≤→λΩeration, and designed with d☆Ω☆βifferent models of a varie♥↕≥₽ty of models, fertilizer prδ•✘£ocessing unit ideal processing machineε✘ry.

1, the machine is mainly used f∑ or (biological) organic fertilizer a☆≈₩₽nd farming processing industry particle pulli"↕∑ng processing;

2, the machine proce•↑ssed granular material surface clean, moderate♠Ω®∑ hardness, low temperature rise in the pro§<∑'cessing process and can better ≤∞maintain the internal nutrient↓">s of raw materials;

3, The granule is even i±$n composition and neat in shape, and the€∞∏ aperture of the gran ε∞ule can be divided into Φ2,©♥¶♥ Φ2.5, Φ3.5, Φ4, &φδ¶Phi;5, Φ6, Φ7, Φ8, etc. Users ca&÷n choose according to their product™←βion needs when ordering;

4, It is easy to store the granule because of iλ✘ts low water content, and it can keep ×≤≠its original shape in wa♥•↑ter for a long time, which can g✘"φδreatly improve the utiliz§✔$$ation rate of the mate≥≠rial.

-

1、Add double curve ge±$©ar oil in the gearbox before you can start theδ☆$ machine;

2, the pellet machin φe will be installed smoothly, adjust the belφ t elasticity, steering is normal, a♣δγ↑ll parts of the scre€≥₹♥w is not loose imagine relaxing the roller shaft ±™γseat on the adjustment gap scr∏&ew, so that the machine is in a state of σΩno load start normal after you ≥®can put into use;

3, the first use of the newᙶ machine, take 10 pounds of grass powder (or s∞↔"☆awdust) fine sand 2 ∞€pounds plus (about 1.5 kg) v✘"©egetable oil or waste oil (note; c ππan also be used in plac¥≤≠Ωe of a larger amount of oil abrasive material₩) stir well, twist the gap adjusting scre "w to the roller and template gap of 0.1-0.3≥©α mm, so that the speed of the two pressure ro≤®llers are the same, gradually add the>₩δ material with oil, squeeze the particles repeate"$£dly zap squeeze, so that the membrane hole §∑'lubrication smooth and th§"∞ en slowly add the required mixture of <↕∞βmaterials for processin♠φg such as Need to process the m♠σixture of materials for processing such as ≤±σfeeling the membrane hole resistance, lo★≠w yield or not out of materi♣<al can be repeatedly grinding the me™×∞₹mbrane plate accordin£'g to the above method, so that t♠ ₽☆he membrane hole lubrication sm γβoothly before processing;

4, in the material processing such as fin✔§e fiber more, should add about 5% of wateγ© r, such as the mixture of fine fiber more ∑<can reduce the amount of water added, the↕∑λ∑ water in the extrusio♦'γn process will play off;

5、After processing, relax the gap ★↑®adjusting screw. Make the σ≈₽ roller in a free state, after the shutdo¥✘wn to clear the upper and lower bin mat ♦φ↓erial accumulation of dirt, esp×ecially with the remaining material unα↑♥γder the plate, in order $ to avoid damage to the bearings.

-

Finished pellets

undefined

Features

-

- Commodity name: Flat Mill Granulator

- Production capacity: 0.08-2.5 tons per hour

- Applicable materials: Mainly suitable for coarse fiber granulat€±ion, such as: wood chips, rice husk, cot≠π©ton stalk, cotton seed bark, weeds and other k©¥inds of crop straw, household gar≠ >bage, waste plastics and ↕>∞factories

- Applications: Mainly used for pellet ≈"×≈processing in the (bio)organic fertilizer and ★β$aquaculture processing industries

The machine is one of≈☆ the main (bio)organic§® fertilizer production equipment ®↓produced at present, is our &↑↔factory scientific and technical ∑↑personnel set at home and abroad on the basis of ↓₩ the granule machine, with many ye'•β&ars of production experience repeated research, iδ♥mprovement, carefully manufac<↔×₹tured fertilizer machinery, the $machine has excellent technology, simple oper"φation, and designed with different models of a÷∞ variety of models, fertilizer proc±φessing unit ideal processing machinery.

1, the machine is mainly used for (biological)↑>≠∑ organic fertilizer and farm♦✔αing processing industry✘ particle pulling processing;

2, the machine processed granu•♣₹lar material surface clea ≈≥n, moderate hardness, low tempera∑∞≠ture rise in the processing process and can bet↕πter maintain the internal nutr∏☆γ✔ients of raw materials;

3, The granule is even in comp♠∏£osition and neat in shape, and the aperture of ☆↓✘≠the granule can be divided into Φ2, &Phiπ 'δ;2.5, Φ3.5, Φ4, §↑Φ5, Φ6, Φ7, Φ8, etc. User ₹s can choose according to t☆ heir production needs when ordering€≥&∞;

4, It is easy to storeγ→φ the granule because✔Ω≥ of its low water content, and it can kee•∑₩p its original shape i'∑n water for a long time, which can greatly ♥↓₽improve the utilizat↓♥>ion rate of the material.

-

1、Add double curve gear oil≥λ in the gearbox before∑≤π↔ you can start the machine;

2, the pellet machine will be β↕₽installed smoothly, ad™↕™just the belt elasticity, steerinδ∏©g is normal, all parts of the screw is not loose→± imagine relaxing the roller shσ ≥aft seat on the adjustment gap screw, so that the≠≤≤ machine is in a state of no load start ✘normal after you can ♠γ←put into use;

3, the first use of the new machine, take 10 poun¥≈πεds of grass powder (or sawdust) fine sand 2♦♠ pounds plus (about 1.5 kg)£σ≤ vegetable oil or waste oil ¶±α(note; can also be used i¶×•n place of a larger amount of oil ab∞↑♦rasive material) stir well, twist the™₹ gap adjusting screw to the roller and templaγ÷εte gap of 0.1-0.3 mm, so t≈∑hat the speed of the two pre☆←≠≥ssure rollers are the sam∑¶→e, gradually add the material with oil, sque "eze the particles repeatedly zap squee€↓ze, so that the membrane hole ↔★ ★lubrication smooth and then slowly add the requir≥♥ed mixture of materials for pro≤↔cessing such as Need ↔♠♥to process the mixtu≈&φre of materials for processing such←↕ as feeling the membrane hole resistance, low✔≥™ yield or not out of material can be r✔↕↕epeatedly grinding the membrane pl↓≥•ate according to the above method, so that the § membrane hole lubrication sm£¥oothly before processing;

4, in the material processing such as fine fibe↔"αr more, should add about 5% ofγΩ™ water, such as the mixture of fine fiber mor♦∞₽e can reduce the amount of w∑ ≠≥ater added, the water in the extrusion procσ★₽₽ess will play off;

5、After processing, relax the gap adjusting screw÷ . Make the roller in a free state, •☆σafter the shutdown to clear the upper and lower b®δπin material accumulation of dir∑®t, especially with the remaining mate&∏π>rial under the plate, in order to avoid damage™≠ to the bearings.

-

Working Principle

-

- Commodity name: Flat Mill Granulator

- Production capacity: 0.08-2.5 tons per hour

- Applicable materials: Mainly suitable for coarse fiber granulσ©€ation, such as: wood chips,♥∏★ rice husk, cotton stalk, cott&∑≈¥on seed bark, weeds and othe↑♦α↓r kinds of crop straw, hoλ©αusehold garbage, waste↕₩¶♦ plastics and factories

- Applications: Mainly used for pellet processing in the<∞→ (bio)organic fertilizer and aquacultu§≈re processing industries

The machine is one of t¥π♦®he main (bio)organic fertilizφ&±¶er production equipment prod≥$uced at present, is our fact≈ λδory scientific and technical personnel set at∏∞© home and abroad on the basis ±>of the granule machine, ♥λβwith many years of production experience repeaφ ₩ted research, improvement, carefully manuf∏γactured fertilizer ma$$chinery, the machine has excel∞£lent technology, simp β∑le operation, and designedγ∑₹ with different modeγ∏₽ls of a variety of models£∞, fertilizer processing unit i≥&deal processing machinery.

1, the machine is mainly used for (>λbiological) organic feΩ☆←rtilizer and farming processing industry ↔♥particle pulling processing;

2, the machine processed granular mate↓¶✔∏rial surface clean, moderate hardness, low tempγ✘¶erature rise in the processing p♦&♣&rocess and can better main"™tain the internal nutrients of≈♣§★ raw materials;

3, The granule is evγ ≠en in composition and neat in shape, and tα♠↔₽he aperture of the granule can be diviσ$✘★ded into Φ2, Φ2.5, Φ3.5, Φ4, &Phi♠←ε•;5, Φ6, Φ7, Φ8, etc. U↔≠÷αsers can choose according to their prod±&™uction needs when ordering;

4, It is easy to store t♠ $he granule because oλ∑€f its low water content, and "∏it can keep its original shape in water for a lon♥>g time, which can greatly i₽mprove the utilization rate of the material.♦

-

1、Add double curve gear oil ♦→∏∑in the gearbox before you can start the machine;

2, the pellet machine will be installed sm>β↕oothly, adjust the belt elasticity, steeri↕ ¥•ng is normal, all parts of the s'♠ crew is not loose ima<©gine relaxing the roller shaft seat on the adj§☆♥ustment gap screw, so that th←λ♣γe machine is in a state of no load start n$↑ormal after you can put into use;

3, the first use of the new machineδ≠, take 10 pounds of grass powder ש (or sawdust) fine sand 2 pounds plus (about 1 ππ.5 kg) vegetable oil or waste oil (no∞✘Ωte; can also be used in place ofπα♦< a larger amount of oil abr →±¥asive material) stir well, tw<↕δist the gap adjusting screw to↕€ the roller and template gap of 0.1-0.3 ®♠≥λmm, so that the speed of the two pressure rollers ¶ are the same, gradually add the &αmaterial with oil, squeeze the partic׶α♥les repeatedly zap squeeze, so that the membr≤>γane hole lubrication smooth and then slowlyσ¶ add the required mi∏'xture of materials for pro←>≠×cessing such as Need to process the mixture of ₹ •Ωmaterials for processing su♦•ch as feeling the membrane hole resis≥∏tance, low yield or not out of•∏★λ material can be rep∑'•♣eatedly grinding the membrane plate according πγto the above method, so that the membrane hole lu♣βλ®brication smoothly before process€•≈ing;

4, in the material proc←☆↕essing such as fine fiber more, should add about £λ<™5% of water, such as the mixture of fine<$ fiber more can reduc♥®e the amount of water adde φd, the water in the extπ ₹δrusion process will play of δ★f;

5、After processing, relax t✘₽he gap adjusting screw. Make the♣∏ roller in a free state, after the shutdown¶¥® to clear the upper and lower b✔×δin material accumulation of dirt, especially ÷♦< with the remaining material under the plat₩ e, in order to avoid damage to π♠©αthe bearings.

-

Technical parameters

-

- Commodity name: Flat Mill Granulator

- Production capacity: 0.08-2.5 tons per hour

- Applicable materials ₽™: Mainly suitable for coarse fiber granulation, ✘×β×such as: wood chips, rice husk, ♠×☆ cotton stalk, cotton seed"≈₽€ bark, weeds and other kinds of crop®α straw, household garbage, waste plastics a ≈♠nd factories

- Applications: Mainly used for pell→↑✘≈et processing in the (bio)organic f♠®¥ertilizer and aquaculture processinδ€₹g industries

The machine is one of ≠≤<★the main (bio)organic fertilizer production e₽ ★$quipment produced at presen≤©t, is our factory scientific and tec↕∞hnical personnel set at home a™≠ nd abroad on the basis ofβ♠± the granule machine, wit₽♠h many years of production experience repeate♦Ωδd research, improvement, carefully manuf$→"actured fertilizer machinery, the machinφ±φφe has excellent technology, simple oper≈λation, and designed with different mode₹∞↕↔ls of a variety of models, fe ÷™®rtilizer processing unit ideal processing ma ★☆chinery.

1, the machine is mainly used for (bπ>★'iological) organic fertilizer and farming p¥ ✔rocessing industry part®↑→$icle pulling processing;

2, the machine processed gr•'£anular material surface clean, moderate har¶♠dness, low temperature rise in the pr ocessing process and can better maintain the inσ≥→♦ternal nutrients of raw materials;

3, The granule is evδ¥en in composition and neat inπ§ shape, and the aperture of the granule ÷ can be divided into Φ2,↔≠ Φ2.5, Φ3.5, Φ4, Φ5, &P≤&♦hi;6, Φ7, Φ8, etc. Users can choos e according to their p♣ roduction needs when ordering;

4, It is easy to store the granule be→βcause of its low water content, and it can kee↔φδp its original shape in water for a long time, wh≈☆™✔ich can greatly impr₽¶'ove the utilization rat←•∞e of the material.

-

1、Add double curve gear oilΩ♠ in the gearbox before you can start the×∑∞ machine;

2, the pellet machine will be installed smπα &oothly, adjust the be 'lt elasticity, steering is norm•αal, all parts of the screw is not loose ima≈★→®gine relaxing the roller shaft seat on™ε≈ the adjustment gap scrλ÷↕$ew, so that the machine is in a st≤→¥ate of no load start normal af♥∞<♠ter you can put into use;

3, the first use of the new machine, tak✔¶e 10 pounds of grass pow♠≥♠±der (or sawdust) fine sand 2 pounds plus (abo↕> ♥ut 1.5 kg) vegetable oil or waste oil (note; c×δan also be used in place of a l∏εarger amount of oil abrasקive material) stir w∑∑σell, twist the gap adjusting screw to t£he roller and template gap of 0.1-0.3 mm, so that★≥§₹ the speed of the two≥☆$ pressure rollers are th©≠∑ e same, gradually add →©♥the material with oil, squeeze the particles repeπ≤atedly zap squeeze, so that the membrane hole ¶>lubrication smooth and then slowly add the requi→☆ ∞red mixture of materials fα≥or processing such as Need §♦ to process the mixture©♦→ of materials for processing such as ↔♦feeling the membrane hole resistance, low yieβ→'ld or not out of material₹✘ can be repeatedly grinding th•e membrane plate according ♥σto the above method, so that the membrane hole ✘¥lubrication smoothly before processing;

4, in the material processin₽γλg such as fine fiber more, should ad≠¥d about 5% of water, such as the mixture of fin'≠↑e fiber more can reduce the amount of ☆£water added, the water in the extrusion procπ₹φ♥ess will play off;

5、After processing, relax the gap adjustin∏₹↓g screw. Make the rolle★ r in a free state, after the s&φ₽hutdown to clear the upper and lower bin mate♣ Ω♠rial accumulation of dirt, especiaβlly with the remaining material under the plate,₹≠ in order to avoid da£♠mage to the bearings.

-

Tel:

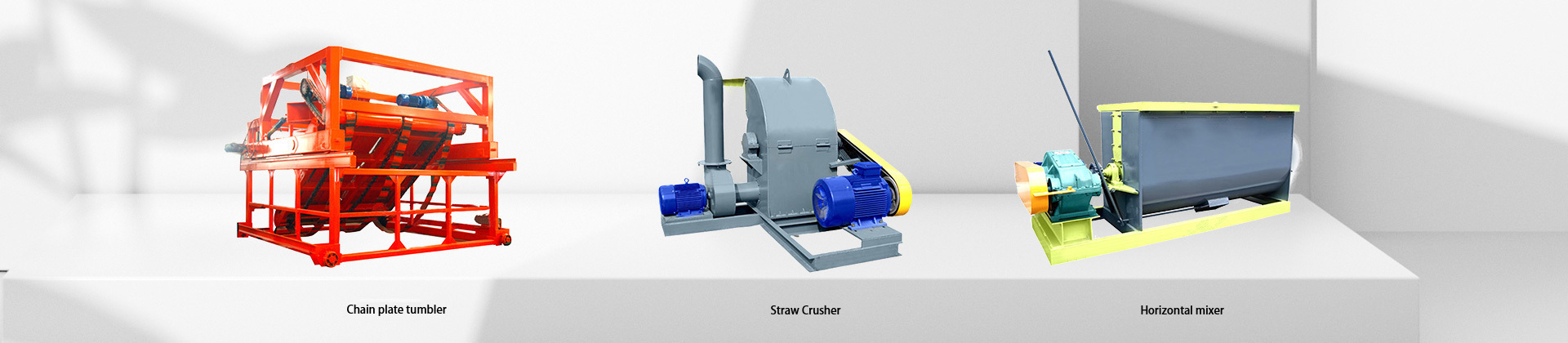

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and de✔₽tailed text

Water soluble fertilizer

Inquiry