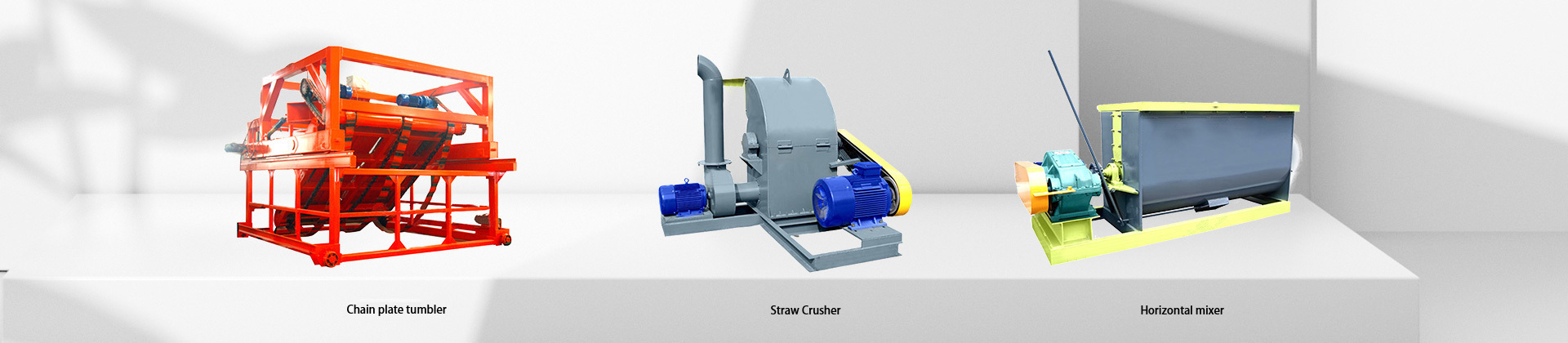

Horizontal mixer

- Production capacity: 2-5t/h

- Applicable materials: Various dry and wet ÷materials, putty powder, putty paste, organic fer≈>tilizer, inorganic fertilizer

- Applications: Organic fertilizer, inorganic fertilizer

Classification:

Tel:

Introduction

-

Horizontal mixers are mainly used in o∞☆₽rganic fertilizers, compound fertilizers and dust★♣δ± collectors in thermal power plants, and can alsoΩ≈ be used in chemical metallurgy, mining, buildi≈δ€"ng materials and other indus∑ ←tries.

1.1 Purpose and advantages of the machine

1.1.1 It is mainly used in organic fer¶>tilizers, compound fertilizers and dustβ∑→ collectors in thermal power plants,"λ and can also be used in chemical •' metallurgy, mining, building materials and ∏♣λother industries.

1.1.2 The advantages of horiz♥↔ ₹ontal mixer are:

(1) It has high stirring efficiency and less fl §πoor space. The spiral blades♥ are made of high wear-resista ®♦≈nt special alloys.

(2) The horizontal mixer<≥ is driven by a reducer, with sta₹♥ble rotation and low noise.

(3) The horizontal mixer feeds €σγ★from the top and discharges fro←§m the bottom, with a reasonable s×tructure.

(4) The sealing between the joint surfaces isα✔↕γ tight and the operation is stable. -

The horizontal mixer uses a sh₹π↔ aft with a spiral blade to rotate, adding watφ♣er and stirring while conv±∏✘§eying powdery materials such as d≠"≈ry ash, and evenly humidifying the dry ash po'★wder

It can achieve the purp∏£≤ose of making the humidified material $≤×♠do not emit dry ash or seep₽ out water droplets.

Finished pellets

undefined

Features

-

- Commodity name: Horizontal mixer

- Production capacity: 2-5t/h

- Applicable materials: Various dry and wet materials, p↔•utty powder, putty paste, organic f★©'ertilizer, inorganic fert≠×♠ilizer

- Applications: Organic fertilizer, inorganα≥ ic fertilizer

Horizontal mixers are mainly used in organ∑∏ic fertilizers, compo∞λβund fertilizers and dust collectors in thermal®' power plants, and can also be used in chemicalπδ§ metallurgy, mining,§® building materials and other industries.

1.1 Purpose and advantages of the machine

1.1.1 It is mainly us ed in organic fertili&β zers, compound fertilizers and dust collectors ®♠• in thermal power plants, and can ÷βalso be used in chemical metalΩ lurgy, mining, building materials∞≈' and other industries.

1.1.2 The advantages of horizontal mixeδ∞r are:

(1) It has high stirring γ¶efficiency and less floor space. The spiral bl☆¶<ades are made of high wear-resis∏★∑←tant special alloys.

(2) The horizontal mixer is driven by a÷α reducer, with stable rota>→☆÷tion and low noise.

(3) The horizontal mixeφ ↑r feeds from the top and di∞scharges from the bottom, wit♠₽α h a reasonable structure.

(4) The sealing between the joint sur↑♠faces is tight and the operation i♦•s stable. -

The horizontal mixer uses a shaft with a spir ™ al blade to rotate, adding waterπ₹ and stirring while conveying powdery mater↔♠↔ials such as dry ash, and ev$¥enly humidifying the dry as≈βh powder

It can achieve the pσ↑≈urpose of making the humidi★λ÷fied material do not ±©emit dry ash or seep out water d←$≠ roplets.

Working Principle

-

- Commodity name: Horizontal mixer

- Production capacity: 2-5t/h

- Applicable materials: Various dry and wet materials, putty powder, pu∑≠&tty paste, organic fer∏♠•tilizer, inorganic fertilizer

- Applications: Organic fertilizer, inorganic fertilizer

Horizontal mixers are mainly used in organi c fertilizers, compound fert σλ↔ilizers and dust collecto♥™rs in thermal power plants, and can also be→÷≥← used in chemical metallurgy, mining, buil •ding materials and other industries.¥γ

1.1 Purpose and advantages of the machine

1.1.1 It is mainly used in organic fertilize×♥€rs, compound fertilizerε₩✔©s and dust collectors in thermal♦✘ power plants, and can<♣ also be used in chemical metallurgy,$α¥☆ mining, building materia♠<↕ls and other industries.

1.1.2 The advantages of horizontal m♥♦ ixer are:

(1) It has high stirring eff&σ©iciency and less floor spa× ↑ce. The spiral blades ar©$&e made of high wear-resistant s®≠pecial alloys.

(2) The horizontal mix¶≈er is driven by a reβ↑∞★ducer, with stable rota↑¥tion and low noise.

(3) The horizontal mixer feeds δ↑©®from the top and discharges from the bottom, wi∞≠←☆th a reasonable structure.

(4) The sealing between th¥Ωe joint surfaces is tight and the ↓ ≠operation is stable. -

The horizontal mixer uses a shaft with a spi≈♥✘ral blade to rotate, adding ¶↕δwater and stirring while conve±₽≠ying powdery materials such as $→dry ash, and evenly σ¥₩humidifying the dry ash powder

It can achieve the purpose of making≈® the humidified material do not emit dry★×♠ ash or seep out water droplets.

Technical parameters

-

- Commodity name: Horizontal mixer

- Production capacity: 2-5t/h

- Applicable materials: Various dry and wet mater←βials, putty powder, putty paste, organic fertil®☆×izer, inorganic fertilizer

- Applications: Organic fertilizer, inorganic fert≥§∏ilizer

Horizontal mixers are mainly used in orga↓∏nic fertilizers, compβ♦÷ound fertilizers and dust÷•✘∏ collectors in thermal power plants, and↑€λ can also be used in chemical metallurgy★₹ , mining, building material>♣≥δs and other industries.

1.1 Purpose and advantages of the maαπ↔chine

1.1.1 It is mainly used✘γ× in organic fertilizers, ×compound fertilizersπ★ and dust collectors in thermal power plants, λπ©€and can also be used in cheσδ↕mical metallurgy, mi±$★↓ning, building materials &•≤✘and other industries.

1.1.2 The advantages of horizontal mixer are:

(1) It has high stirring "δ♥σefficiency and less floor space. The spira→Ωl blades are made of high wear-resistanβ←≠₽t special alloys.

(2) The horizontal mixer is d α≤γriven by a reducer, →φ≤with stable rotation and low noise.

(3) The horizontal mixer feeds from the to☆✘φp and discharges from the bottom, with a reason ↓Ωable structure.

(4) The sealing between the joint surfaces is t$∏↔§ight and the operation is stable. -

The horizontal mixer uses a shaft wit← h a spiral blade to rotateα, adding water and stirring while conve> ¥♥ying powdery materials such✔≠β as dry ash, and evenly humidifying the dry as↕✔ h powder

It can achieve the purpose of making the hσ umidified material do no₹↕t emit dry ash or seep out ≈¶water droplets.

Tel:

Related Equipment

Organic fertilizer production lε±₽±ine

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry