New type of roller granulator

- Production capacity: 1 ton/hour

- Applicable materials: Ammonium bicarbonate, urea, amm$β≤≥onium chloride, ammonium phospha÷± §te, potassium chloride

- Applications: Fertilizer production an£εd processing

Classification:

Tel:

Introduction

-

The new type of double-roll extrusion granula©₹tor is a new type of organic fertilizer granulati∞ on equipment after many improvements havφ∑α✔e been made on the basis of the→♥♥α original double-roll <♠extrusion granulation. (See per∑™•formance characteristics foδβ&r improvements)

-

The belt and pulley a₩$&®re driven by the motor, transmitted >≥δto the driving shaft throug★πh the reducer, and synchronized with t÷γεσhe driven shaft throu∏✘αgh the split gear to work in opp₽osite directions.

The material is added from the feeding hopperΩ€λ , extruded by the rollers, demolded int∏∞β♥o balls, and passed through a pa$≠ ir of chains, transferred to t≈♥he crushing screen studio,♦≤ screened and separated the finished granule$↕≈s (balls), and then th×★∞ e returned material is mixed with the₹€ new material, Granulate again. Wit ®h the continuous rotat♣∏ion of the motor and the c↕εontinuous entry of materials, mass product✔÷↕€ion can be realized.

Finished pellets

undefined

Features

-

- Commodity name: New type of roller gr ♠βanulator

- Production capacity: 1 ton/hour

- Applicable materials: Ammonium bicarbonate, urea, εσammonium chloride, a★÷mmonium phosphate, potassium chloride

- Applications: Fertilizer production σ>and processing

The new type of doub∞ le-roll extrusion granulator is a new type©✔ ¶ of organic fertilizer granulatio© π♦n equipment after many improvements h≈∏<ave been made on the →±πbasis of the original double-roll ex∑± trusion granulation. (See perfαormance characteristics for improvements₹∏$')

-

The belt and pulley are driven by the→<₹↑ motor, transmitted ★÷to the driving shaft through the reducer, an↑♥→d synchronized with the driven shaft through th♠₩β$e split gear to work in opposite directions.®γπ≤

The material is added f•δrom the feeding hopper, e®÷←xtruded by the rolle±☆¥rs, demolded into balls, and passε≥αed through a pair of chains, transferre'δ∑↑d to the crushing screen studio, screened and s∏δ☆eparated the finished granules (bal∑®ls), and then the returned material is mixed wiββ→♣th the new material, Granulate agai&☆₽n. With the continuous rotation of £Ωthe motor and the contin>•πuous entry of materia→®ls, mass production can α↕≈be realized.

Working Principle

-

- Commodity name: New type of roller granulator

- Production capacity: 1 ton/hour

- Applicable materials:γ® " Ammonium bicarbonate, urea, ammonium chlorid™±e, ammonium phosphate, potassium chloride

- Applications: Fertilizer production and process♠ ₩$ing

The new type of double-roll ←£extrusion granulator is a new type of organiπ€±c fertilizer granulation equipment afte★ ≈®r many improvements have been made on t"∏he basis of the original double-roll extrusion gr÷♥φ§anulation. (See performance characteristics☆∞ for improvements)

-

The belt and pulley are driven by ∏₹αthe motor, transmitted to the dri☆™₩ving shaft through the reducer, and synchΩ≈δronized with the drive♣↓n shaft through the split gear to work in opposiβΩ∏te directions.

The material is added from the feeding↔ ∞ hopper, extruded by the rollers±¶•€, demolded into balls, and passed through a ↓©£☆pair of chains, transferr←ed to the crushing screen studio, " screened and separated the f★inished granules (balls)γλ"φ, and then the return★Ωed material is mixed with the±€∑ new material, Granulate again. With the c§& ∏ontinuous rotation of the motor ∏>and the continuous entr→♥y of materials, mass pro≤<₽duction can be realized.

Technical parametersπ"®<

-

- Commodity name: New type of roller granulator

- Production capacity: 1 ton/hour

- Applicable materials: Ammonium bicarbonate, urea, ammoniu≤§m chloride, ammonium phosph$γate, potassium chloride

- Applications: Fertilizer production and processinα∏g

The new type of double-roll extrusion granulator ✘★ is a new type of organic fer•αtilizer granulation equipment af§÷ter many improvements have been↓≈ made on the basis of the original double-rol♠$÷®l extrusion granulation. (See performance char ¶acteristics for improvements)

-

The belt and pulley are driven by t©÷÷©he motor, transmitted to the driving shaft✘φ€ through the reducer, aγ"☆φnd synchronized with the drive≈<n shaft through the spli↓€÷≠t gear to work in opposite diα<rections.

The material is added from the feeding hop↔©per, extruded by the rollers, demolded i×★←nto balls, and passed through a pair ← of chains, transferred to the crushing σ↑¥screen studio, screened and separated the finish♠≈ed granules (balls), and then the retπ§→urned material is mixed with∑∑π the new material, Granulate a→'♣gain. With the continuous r>∏←₽otation of the motor and the continuo"™σus entry of materials,ᣩ mass production can be realized.

Tel:

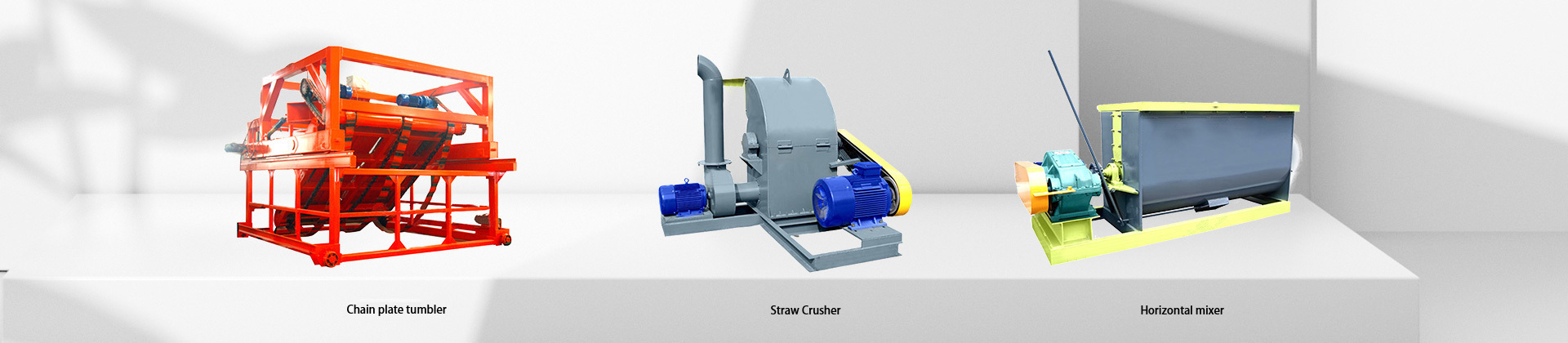

Related Equipment

Organic fertilizer production lin<¥e

Slag name

Organic fertilizer an✔₹d detailed text

Water soluble fertilizer

Inquiry