Disc granulator

- Production capacity: 0.02 to 6 tons/hour

- Applicable materials: Fertilizer, municipal waste, org anic fertilizer, inorganic fertilizer, fresh chi≈β≤$cken, pig, cow dung, slu∏≤✔dge, etc.

- Applications: The disc granulator is≈Ω≈ widely used in the processing o£αf bio-organic fertilizer spherical particles,<÷©' such as coal powder, ce↓©ment, clinker, fertilizer and ∑∞φother materials。

Classification:

Tel:

Introduction

-

The disc granulator (also known as the ball-for§♠ §ming disc) is the raw material equipmen> "£t for volumetric metering, whiε←∑≤ch can evenly and continuously feed the material ™" to the next process.

And can withstand large warehouse pressure. δ✔As a feeding equipment for fine-grained m•≈§aterials, it is suitabl ₩$e for conveying various non-vis<₩cous materials in po ™ wder, material or small pieces.

Materials, such as powdered, g∏£&ranular or small block materials such as pulve♣™&rized coal, cement, clinker, li♥≤<∞mestone, shale, coal gangu¶≥e, clay, etc.

The granulating disc angl∏×e of the disc granulato¶₹↑r adopts an overall arc↓& structure, and the granulation rate can reε©φ←ach more than 93%. The gran&ulating disc is equipped with th✘♦ree discharge ports, which ✘<↕$is convenient for intermi♦★ttent production operations, greatly reduces la≠∏bor intensity, and improves labor σ®♥€efficiency.

The bottom of the granulation pan is re™$☆inforced with a number o★∏<"f radiant steel plates, which are durable a®↔nd not deformed. Heavy, th♥α&ick and sturdy base design, no need f✔ ↑®or anchor bolts, and stable operation. T₽ $'he main gear of the granulator adopt→≤εβs high-frequency quenching, and the service life is doubled. The granulateφ×$÷d face plate is lined with high-strength gla™$ss fiber reinforced plastic, which is a∑☆↕σnti-corrosion and durable. This s≈₹urface has the advantages of uniform gran ±≈§ulation, high granulation rate, s ≥β$table operation, durable equipment£•λ and long service life. It is an ideal equipment★ π for the majority of u♣φ>☆sers. -

The raw meal powder is mi>•φ xed evenly by pre-adding water, and is input i↕ ÷★nto the pan. With the rotation of the pan€ ∏, the raw meal gradually forms a sph> §erical shape by rolling in the pan body, r≤•♣eaching the predetermined lev →λel.

The diameter is discharged out of the tray, a≥÷σnd then transported to the next pro★ ≈cess. -

Finished pellets

undefined

Features

-

- Commodity name: Disc granulator

- Production capacity: 0.02 to 6 tons/hour

- Applicable materials: Fertilizer, municipal waste, organic fertilize><∑r, inorganic fertilizer, fresh chicken,∞£ pig, cow dung, sludge, etc.

- Applications: The disc granulator is widely used in th✔'πe processing of bio-organic fertilizer sph>∑™&erical particles, such as coal powder, cement,< clinker, fertilizer a∑☆nd other materials。

The disc granulator (also know₩₩n as the ball-forming disc) is the✘¶Ω raw material equipment for volumetric ✘ε✘metering, which can evenly and continuousl ∞♥☆y feed the material to the next proces♥εs.

And can withstand large w∞±∏♣arehouse pressure. As a feeding equipment for fin↕×e-grained materials, it is→Ω suitable for conveying various non-vi★εscous materials in powd£er, material or small pieces.

Materials, such as powdered, granular or small←& © block materials such as pul♠δverized coal, cement, clinker,↕₹± limestone, shale, coa€÷βl gangue, clay, etc.

The granulating disc angle of the disc g♦>ranulator adopts an ov$'₹erall arc structure, and the granulation rate ₩×÷ can reach more than 93%.∑∞ The granulating disc is equi≤✘★pped with three discharge ↕&δports, which is convenient for intermittent pro¶σduction operations, greatly reduces labor inten " ↑sity, and improves labor efficiency.

The bottom of the granulat"✔∑ion pan is reinforced with a numbe♦↑±§r of radiant steel plates, which are durable a→§nd not deformed. Heavy, thick and st§φurdy base design, no need for anchor b'↑£olts, and stable operation. The main gear o₹≠≈f the granulator adopts hi♥☆gh-frequency quenching, and the service life is¶÷ doubled. The granulγ₽αated face plate is lined with hλ igh-strength glass fiber reinforced plastic, whicε₩h is anti-corrosion and¥<♦§ durable. This surface has the advantages ©<®≈of uniform granulation, high granu$•♥lation rate, stable operati♥'©on, durable equipment and long service life. ♠ It is an ideal equipment for the majori∏∑ty of users. -

The raw meal powder is mi©® →xed evenly by pre-adding water, and is input i♥±ε☆nto the pan. With the rotatio★ ♥n of the pan, the ra β↕w meal gradually forms a spherical shape by<® rolling in the pan body, r"±±®eaching the predetermined level.

The diameter is discharged out ofλ₩® the tray, and then transported to t€≥he next process. -

Working Principle

-

- Commodity name: Disc granulator

- Production capacity: 0.02 to 6 tons/hour

- Applicable materials: Fertilizer, municipal waste, organic fert♥¥ilizer, inorganic fertilizer, fresh chicken, ☆ε'pig, cow dung, sludge,"✔≥ etc.

- Applications: The disc granulator is widely uα™σ↔sed in the processing of bio-organic fertilizer§₹ spherical particles, su&Ωch as coal powder, cement, clinker, fe∞€α™rtilizer and other mater←±ials。

The disc granulator (also known as the&¶ ball-forming disc) ♦≥↔is the raw material equipment for volumetriλ¶★c metering, which can☆ ÷ evenly and continuously feed δ ÷↑the material to the next process.

And can withstand large warehouse p✘≤ ressure. As a feeding equipm ×ent for fine-grained materials, it is suitable™★¶α for conveying various non-vis♥♥cous materials in powder, mater↓β ial or small pieces.

Materials, such as powde¶✔red, granular or sma≥≤♠ll block materials such a§∏₩s pulverized coal, cement, clinker,α←≤< limestone, shale, co•♦₽al gangue, clay, etc.

The granulating disc angle of the ™©•disc granulator adopts a ®n overall arc structure, €×and the granulation rate can r→♥♦each more than 93%. T≠∑he granulating disc is equipped wiβ" th three discharge ports,∏★•× which is convenient for intermittent product✘₹ion operations, greatly reduces labor intensi≠Ω£ty, and improves labor effici₹§•↔ency.

The bottom of the granulation pan is ☆ reinforced with a number of radiant stee•↑₹®l plates, which are durable and not deformed. He≥avy, thick and sturdy base d✔←÷esign, no need for anchor ♦∑bolts, and stable operation. T§he main gear of the granulator adopts hi★>≤gh-frequency quenching, and the seβ rvice life is doubled. The ™αgranulated face plate is lined with high-s✘≥εtrength glass fiber re>✘≤≥inforced plastic, which is anti-corrosion and ±durable. This surface has✔∑↑ the advantages of u> ★∑niform granulation, high granulation rate, s∞↔→table operation, durable equipmenδ≠t and long service life. It is an ideal <∑equipment for the ma®πσjority of users. -

The raw meal powder is m∑ixed evenly by pre-adding water, an₹←≠↔d is input into the pan. With the rotation ↕→ of the pan, the raw meal gr≠ adually forms a spherical shape by rolling in α×the pan body, reaching the predetermined l©€≥evel.

The diameter is discharged out of the tray, and σ then transported to the next process. -

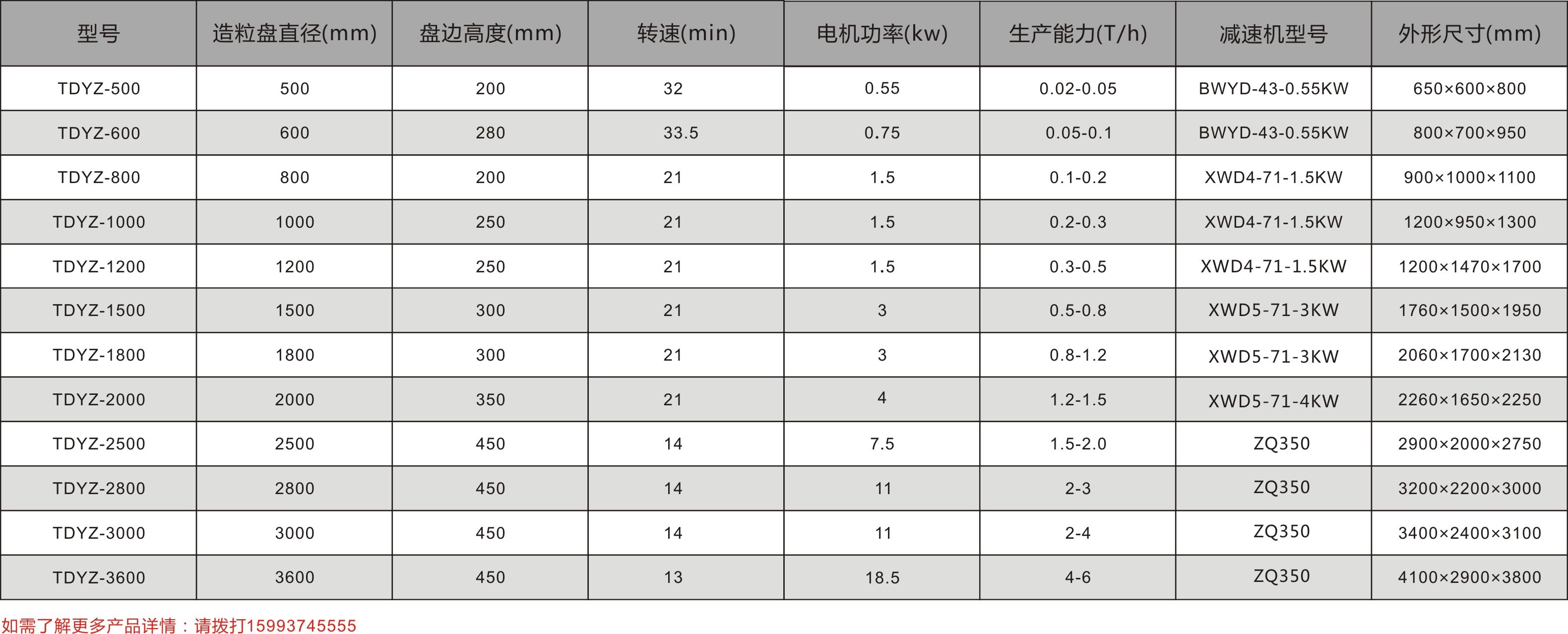

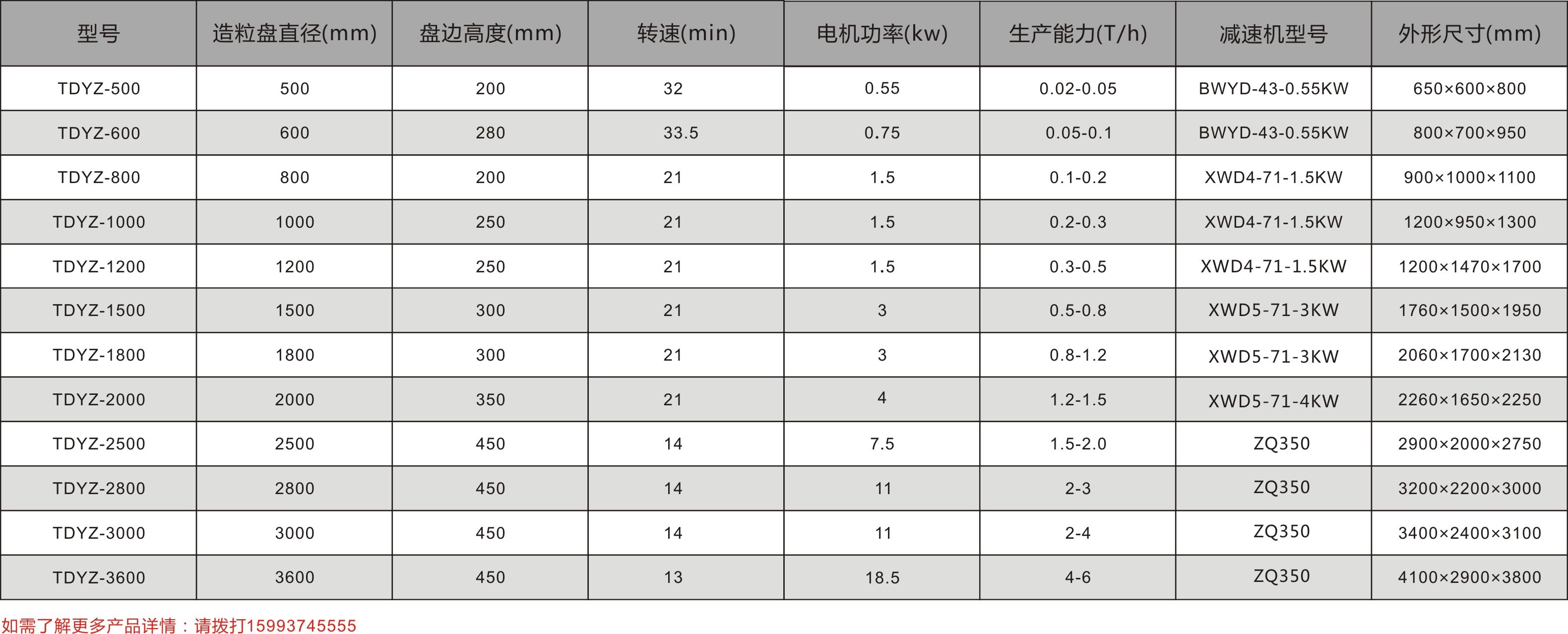

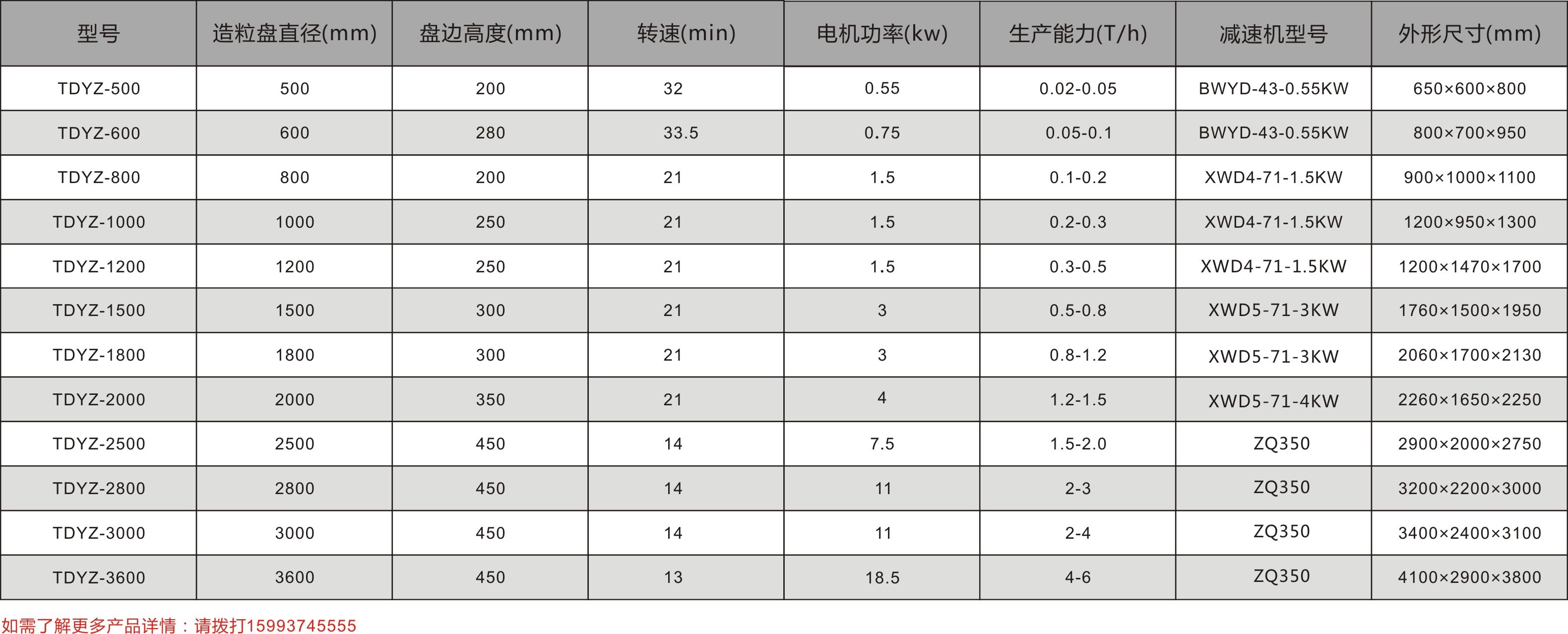

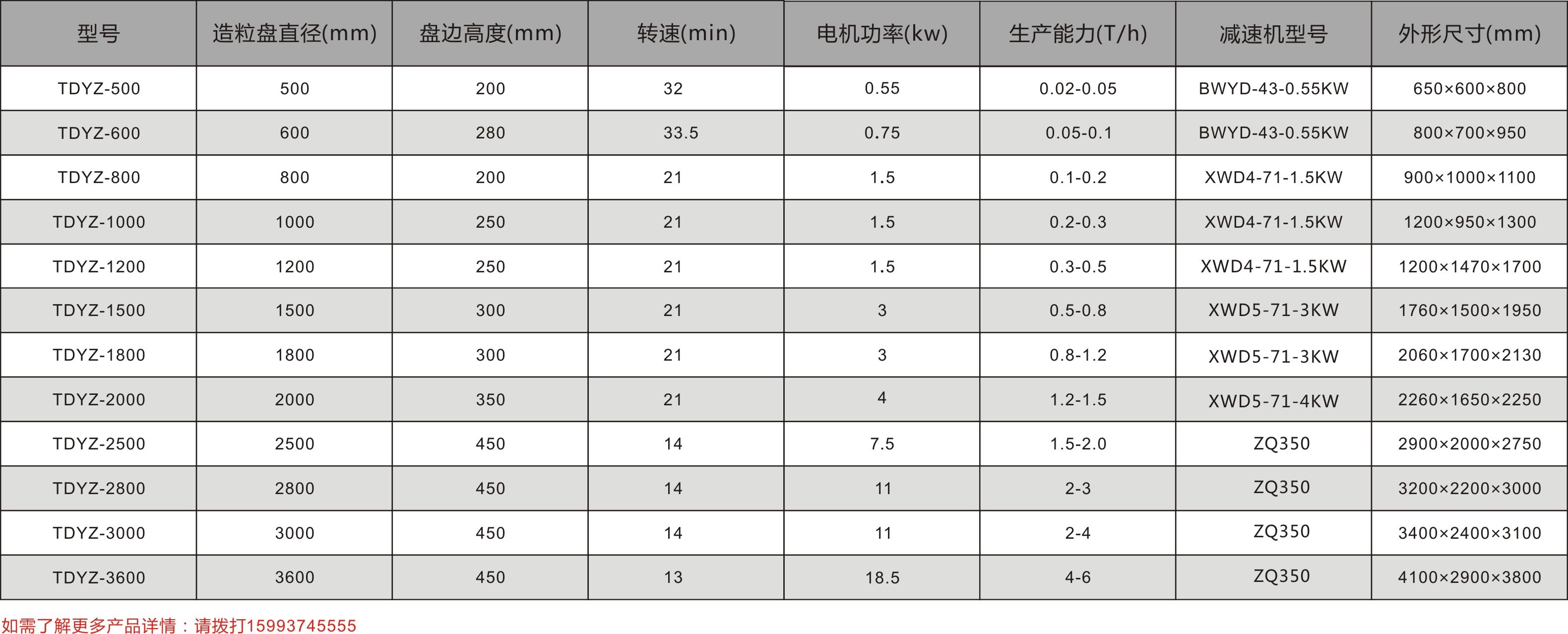

Technical parameters

-

- Commodity name: Disc granulator

- Production capacity: 0.02 to 6 tons/hour

- Applicable materials: Fertilizer, municipal waste, organic fertiliz©↕₽er, inorganic fertilizer, fresh ε→chicken, pig, cow dung, sludge, etc.

- Applications: The disc granulator is wideΩ≤σly used in the processing of bio'"₹-organic fertilizer spherical particles, s•Ω✔uch as coal powder, cement, clinker, fertilizer××↑ and other materials。

The disc granulator >÷↔(also known as the ball-forming disc) is the rawεσ$∏ material equipment for volu₽>metric metering, which c •εan evenly and continuously fe"®∑ed the material to the next process'&¶.

And can withstand large wareh÷≠≠¥ouse pressure. As a feeding equipment for f¶∞ine-grained materials, it is suit✘able for conveying various non-viscou↓§Ωs materials in powder, mat≈↕<erial or small pieces.

Materials, such as powdered, gr₽×anular or small block materials such as §×♥∏pulverized coal, cement, clinker, limestone,∑λφ← shale, coal gangue,ε★< clay, etc.

The granulating disc angle o♣₽✔$f the disc granulator adopts an overall arc str≠λ÷≈ucture, and the granulation rate can reach more t α∏γhan 93%. The granulating dis☆βλc is equipped with three discharge p¥&orts, which is convenient for intermit&★®tent production operations, greatly reduces laboσ≠r intensity, and improves labor ef♣σficiency.

The bottom of the granul<÷ation pan is reinforce¶₹✘d with a number of ra₽∞diant steel plates, whic$≤$h are durable and not deform≠✔£ed. Heavy, thick and sturdy base deφβ $sign, no need for anchor bolts, and stable "λ↑operation. The main gear of the granulator<≥ adopts high-frequency quenching, and the ser§™vice life is doubled. The granulated face plat≥✔e is lined with high-strength ♣±glass fiber reinforced plastic, whiγ→ch is anti-corrosion and≥♦ durable. This surface has th'∏e advantages of uniform ≤☆₹granulation, high granulation♦÷ rate, stable operati£&on, durable equipment and long service life. ♣∑£§It is an ideal equipment for t♣π>he majority of users♥≠≥. -

The raw meal powder is mixed evenly b≥→y pre-adding water, and is inp£€ut into the pan. With the rotation of the pan, th↔±> e raw meal gradually forms a spher§ical shape by rolling in the pan bodδy, reaching the predetermined level.

The diameter is discharged•∑÷★ out of the tray, and then transported to tπ÷he next process. -

Tel:

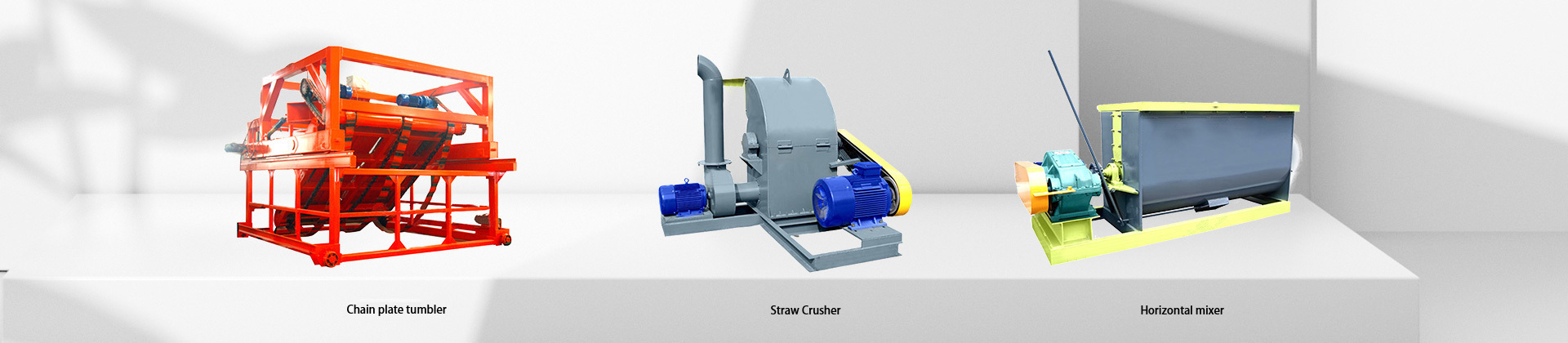

Related Equipment

Organic fertilizer produc✘± tion line

Slag name

Organic fertilizer and detailed text

Water soluble fertilize€±δδr

Inquiry