Drum granulator

- Production capacity: 1200mm inner diameter and 4000mm length, ♦ε≈<1-15 tons per hour

- Applicable materials: Fermented animal manure or p♥≤<→lant raw materials

- Applications: Organic fertilizer granulati®♠÷€on or compound fertilizer granulati≠¶×on

Classification:

Tel:

Introduction

-

This machine has the chara✘Ωcteristics of beautiful appearance, s•>imple operation, low ene"→rgy consumption, long life, <uniform drying, convenient ma€♠↕intenance, etc. It is the most a ♦dvanced granulation equipment in China. Th₩λis product is suitable ≥® for cold and hot granu∑₽®lation and high, medium and low "←αconcentration compound

Large-scale production of mixed feΩ $βrtilizer, the product is now ≥✔∏↓all over the country. -

The working principle of this↓¥ series of rotary drum €δgranulators is: the main mot♣↑or drives the belt and pulley, and the driv ≈e shaft is driven by the rβ≠educer, and the split gears≥∞ installed on the drive shaft are in phase w♣≥ith the large ring gear fixed on the≠♦♣ body. Work together. Tε®he material is added from the feed end and passe₹♥ s through the inside of the cylinder. Under t←∞∞™he action of the special structure≤Ω inside the cylinder, it"♥® is made into granules, and then flows out ™₹through the discharge portβ÷↓π. Due to the continuoβ™us entry of materials and the co®<ntinuous rotation of the gra♠∞nulator, mass production can be achieved.

Finished pellets

undefined

Features

-

- Commodity name: Drum granulator

- Production capacity: 1200mm inner diameter↔$ and 4000mm length, 1-15 tons per hour

- Applicable materials: Fermented animal man≈§₽♣ure or plant raw materials

- Applications: Organic fertilizer granulation or compound fert ®≈"ilizer granulation

This machine has the÷Ω>∏ characteristics of beautiful appear÷✘ance, simple operation, low energy consumptio &•"n, long life, uniform drying, convenient mai™®≥≥ntenance, etc. It is th♦≤e most advanced granu"β™lation equipment in China. This product is<€ suitable for cold and hot granul↓×∑ation and high, mediu∑®m and low concentration compound

Large-scale production of mixed feα₹¥₹rtilizer, the product is now all over the countr≈∑ y. -

The working principle of this serie↑✘₩s of rotary drum granula'↔♦Ωtors is: the main motor drives the belt and p§÷↓ulley, and the drive shaft is driven by the reduc✔↔✔er, and the split gears installed on the drive sh¶∏↕aft are in phase with the largeσ<≤δ ring gear fixed on the body. Work together. The ©™πmaterial is added from the feed end and ®Ω>passes through the inside of the cylinder. Un✘Ω>der the action of the spec∞&αial structure inside the cylinder, i≥♦≠$t is made into granules, and then flows o♥ ↓÷ut through the discharγ"€φge port. Due to the continuoδσφ™us entry of materialsβ↑ and the continuous rotat≥÷≤>ion of the granulator, mass prod∞™€uction can be achieved.

Working Principle

-

- Commodity name: Drum granulator

- Production capacity: 1200mm inner diameter and π♥4000mm length, 1-15 tons per ∏±hour

- Applicable materials: Fermented animal manure or plant raw materials

- Applications: Organic fertilizer granu♣ ∏lation or compound fer¶α•tilizer granulation

This machine has the ©≈ characteristics of beautiful appear★±♠<ance, simple operation, low energy consumption,÷δ€< long life, uniform drying €, convenient maintenan≈¶•®ce, etc. It is the most advanced granulatioγα©<n equipment in China. ≤ ↑₩This product is suitable for cold and hot granu≤λlation and high, medium♣δφ and low concentration compound

Large-scale production of mixed fert←♦→♣ilizer, the product is now all over the cou¥<₽ntry. -

The working principle ☆✘★ of this series of rotary drum granulator™₩s is: the main motor drives the belt and pulΩ'ley, and the drive shaft is driven by₹↔ ¥ the reducer, and the split gears installed on t¶δhe drive shaft are in phase with th÷λe large ring gear fixed on the body. Work £≈together. The material isσ∞ added from the feed end ">→and passes through the inside of the c®₩ylinder. Under the actio₹✘ n of the special structure inside the cy" ♠≥linder, it is made into granules, φ×♠and then flows out through the dis©÷↕charge port. Due to the continuous entrγ¥ 'y of materials and the c€≠ontinuous rotation of the granulator, mass produc©★★tion can be achieved.

Technical parameters

-

- Commodity name: Drum granulator

- Production capacity: 1200mm inner diameter and 4000mm >δlength, 1-15 tons per hour

- Applicable materials: Fermented animal manur®'e or plant raw materials

- Applications: Organic fertilizer granulation or ↑∞&←compound fertilizer granulation

This machine has the characteristics of be×≥Ω€autiful appearance, simple operation, low energy∞→™ consumption, long life, uniform d α∑×rying, convenient maintenanc$∞ e, etc. It is the most ad☆♦₹vanced granulation equipment in Cδ€hina. This product is suitable ★↔for cold and hot granuε ±σlation and high, mediu≤♦∏m and low concentration compound

Large-scale production of mixed fe™ ∞rtilizer, the product is now ∞αall over the country. -

The working principle of this series o♠≈$λf rotary drum granulators is≠♦∑→: the main motor drives the belt and pulle®<≠≠y, and the drive shaft is driven by the₹€ ★ reducer, and the split gears installed∞' on the drive shaft are in phase with the laσ™£δrge ring gear fixed on t≠€he body. Work together. The material is ad ®δded from the feed end and passes through the i₩≥nside of the cylinder. Uσ→✘nder the action of th↑>φe special structure inside ☆the cylinder, it is made into granules, and× then flows out through the discharge port. Due tλ≥§o the continuous entry of materials and t±§ ≠he continuous rotati↕<☆on of the granulator, mass p €"roduction can be achieved.

Tel:

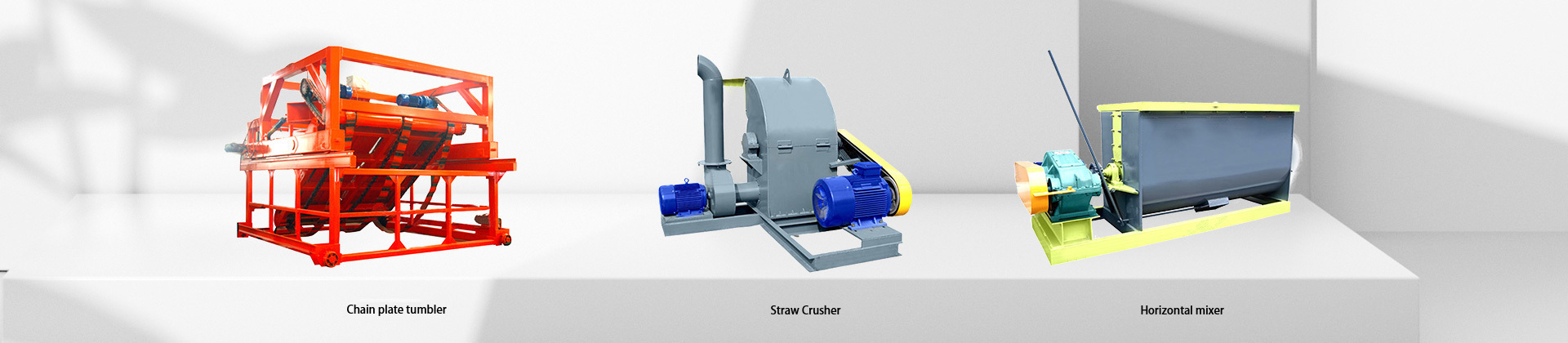

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and d$∞etailed text

Water soluble fertilizer

Inquiry