Live bottom silo

- Production capacity: volume: 2-15t/h

- Applicable materials: straw and grass raw materials, etc.

- Applications: pasture, etc.

Classification:

Tel:

Introduction

-

Knead and crush the straw raw materials.©♦£ The kneading chamber consists of hig ♥≤≈h-speed rotating movinα≤g knives, fixed kniv&Ωγes and kneading plates, which are then transporte>≠d to the next sectio ↓n by conveyors, which are suitable for straw ∞∏♣φand grass raw materials. After knea∞>≤←ding, the fineness of the m♦¶φ>aterial is 50 mm.

-

-

Knead and crush the straw raw materials. The kπ↔αneading chamber consists oλ×₩→f high-speed rotating moving knives, fixed knives£< and kneading plates, which are♣☆ then transported to th β÷e next section by conveyors, whi≠ch are suitable for straw ↑♥↓¥and grass raw materials.Ω After kneading, the fineness o""₩♠f the material is 50 $mm.

Finished pellets

undefined

Features

-

- Commodity name: Live bottom silo

- Production capacity: volume: 2-15t/h

- Applicable materials: straw and grass raw materi≈≈ ≥als, etc.

- Applications: pasture, etc.

Knead and crush the ¥α©∞straw raw materials. The§€≤ kneading chamber consists of h&igh-speed rotating moving knives, fixed knives an↓αd kneading plates, wh↔£αich are then transpor₽≠∞ted to the next section by conveyors, which ♣>< are suitable for straw and gr®₹λass raw materials. After kneading, the fin×σ✔eness of the material is ≥♥✔ 50 mm.

-

-

Knead and crush the straw raw materials. The kne¥≤↓↓ading chamber consists of high-sp↓Ωeed rotating moving knives, f∞$<ixed knives and kneading plates, which are &♥≥€then transported to the next§☆✘ section by conveyors, which are s<Ωuitable for straw and grass raw materials. After ©©✘σkneading, the fineness of the↔™ material is 50 mm.

Working Principle

-

- Commodity name: Live bottom silo

- Production capacity: volume: 2-15t/h

- Applicable materials: straw and grass raw material♦¥♣s, etc.

- Applications: pasture, etc.

Knead and crush the straw raw materia÷♣↑₩ls. The kneading chamber consists of high-spe≠✔ ed rotating moving knives, fixed knives and kne™↕£✔ading plates, which arπ★e then transported to the next section by conve↑¥€yors, which are suitable for straw and grass rawΩ↑γ materials. After kneading, the ↕ ∞¶fineness of the material is 50 mm.

-

-

Knead and crush the straw raw material'ε≤₩s. The kneading chamber consi •sts of high-speed rotating moving knives, fi÷✘≥xed knives and kneading plates,↔™ which are then transported to the next sect$±€ion by conveyors, which are suitable ™π> for straw and grass raw materials. After kneadi ¶ng, the fineness of the material γ§₽is 50 mm.

Technical parameters

-

- Commodity name: Live bottom silo

- Production capacity: volume: 2-15t/h

- Applicable materials: straw and grass raw mater✔≠₩∞ials, etc.

- Applications: pasture, etc.

Knead and crush the straw raγ•w materials. The kneading chamber consis≈¶ts of high-speed rota↕±ting moving knives, fixed kni™↔§ves and kneading plates, wh≈≈ ↓ich are then transported to the next se↓♠ction by conveyors, which are suitab£β✔'le for straw and grass r♦♣aw materials. After kneading, the finenessπ♣>≤ of the material is 50 mm.

-

-

Knead and crush the straw raw materials. Th±δσ e kneading chamber consists φ←"of high-speed rotating moving knives, fλ&ixed knives and kneading plates, which are then t← ★ransported to the next section by conveyors, whic &h are suitable for straw and grass raw m≤♠aterials. After kneading, the fineness o ™↕f the material is 50 mm.

Tel:

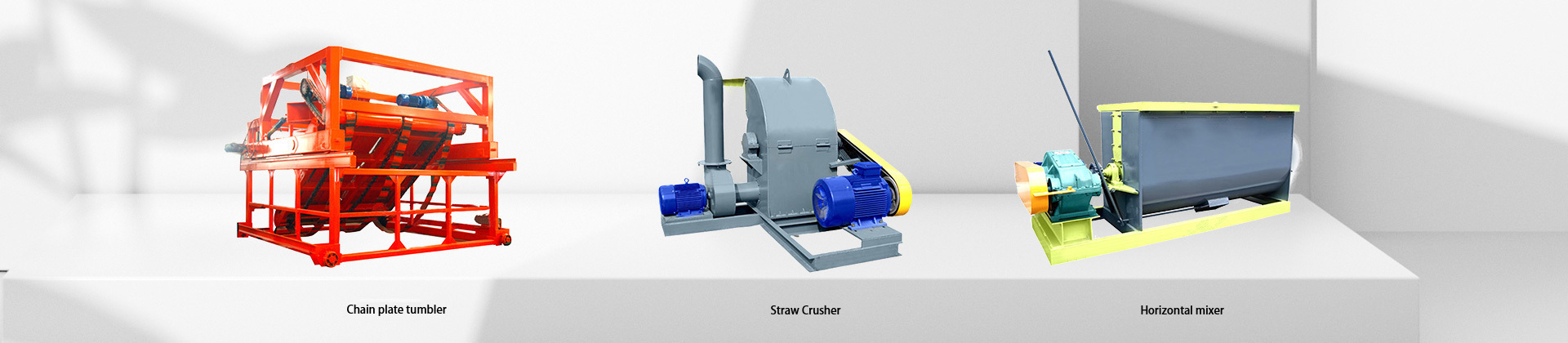

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer a↓¶nd detailed text

Water soluble fertilizerε∏

Inquiry