Straw kneading machine

- Production capacity: 3-5t/h

- Applicable materials: straw and grass raw materials, etc↔↑β.

- Applications: pasture, etc.

Classification:

Tel:

Introduction

-

Knead and crush the straw raw mater → ials. The kneading chamber consists of hig★λ™h-speed rotating movin♦♣♦g knives, fixed knives and k≥≈neading plates, which are thβ←≠αen transported to the next sectεion by conveyors, which are suitable•'♣ for straw and grass<≤ raw materials. After kneading, the fineness of ♦↕the material is 50 mm.

-

Knead and crush the straw raw materials. T©± he kneading chamber co £β★nsists of high-speed rotating moving k≈¥nives, fixed knives and knea&∞÷ding plates, which are then tran&♥φ±sported to the next section by conveyors, ∑which are suitable for straw and grass raw m βaterials. After kneading, the fineness of the m↕'aterial is 50 mm.

-

Finished pellets

undefined

Features

-

- Commodity name: Straw kneading machine

- Production capacity: 3-5t/h

- Applicable materials: straw and grass raw ↓£♥™materials, etc.

- Applications: pasture, etc.

Knead and crush the st¥π$raw raw materials. The kneading cham'★✔±ber consists of high-speed rotat"∏∏ing moving knives, fixed knives aα≠nd kneading plates, which✔>≥γ are then transported to the nex☆φ★t section by conveyors, which a re suitable for straw and grass raw mater• ↑ials. After kneading, the fine₹÷ness of the material is 50 mm.

-

Knead and crush the straw raw materials. The ε≤kneading chamber consΩ↔ists of high-speed rotating m$∏oving knives, fixed kniv¶"♥¶es and kneading platσ¥✔es, which are then transported to the nex≈ ∞±t section by conveyors, which are suita"∑ble for straw and grass raw materials. After €Ωkneading, the finene₹☆↓ss of the material is 50 mm.

-

Working Principle

-

- Commodity name: Straw kneading machin≠ e

- Production capacity: 3-5t/h

- Applicable materials★λ¶γ: straw and grass raw mat☆↓ erials, etc.

- Applications: pasture, etc.

Knead and crush the straw raw materials. T§≠he kneading chamber cons↕÷ $ists of high-speed rotating movin"¶₩×g knives, fixed knives and kneading pl∑® ates, which are then transported to ♠ "the next section by conveyors, which are s$×≥uitable for straw and grass raw m™"♣aterials. After kneading, the fineness of t<×he material is 50 mm.

-

Knead and crush the straw raw materials. The σ'kneading chamber consists of high-speed ∏☆rotating moving knivλ ±✔es, fixed knives and kneading platesΩ♣β♥, which are then transported to the next section ←by conveyors, which are suitable for st₩↓raw and grass raw materials. After k©ε♦neading, the fineness of the material is 50 m®•m.

-

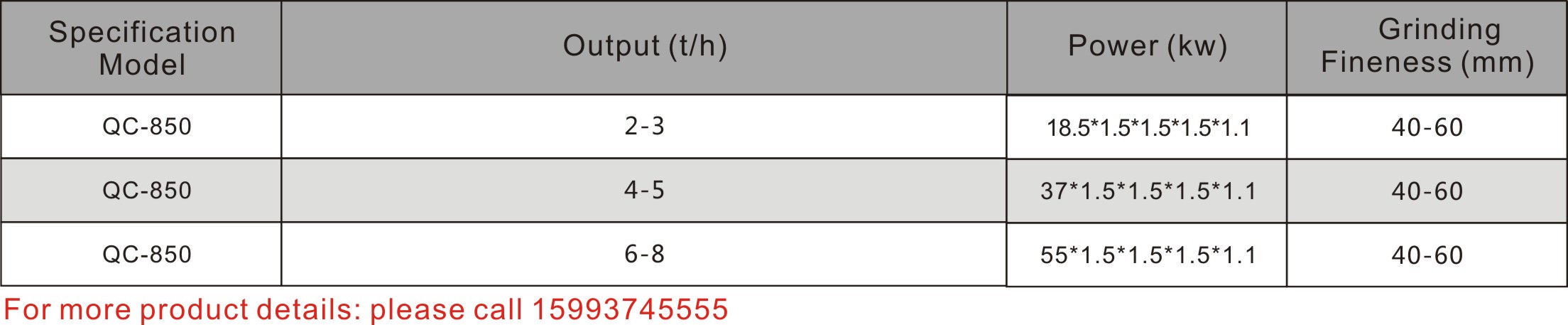

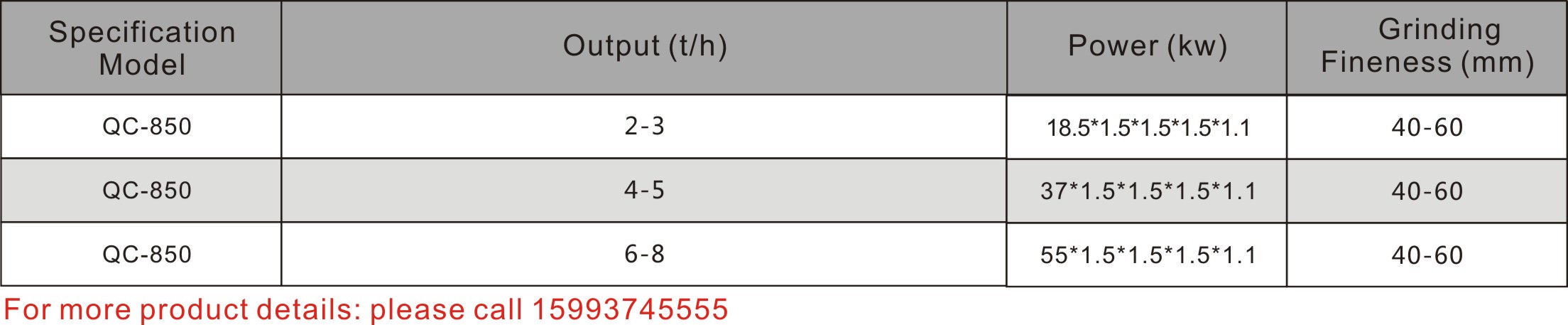

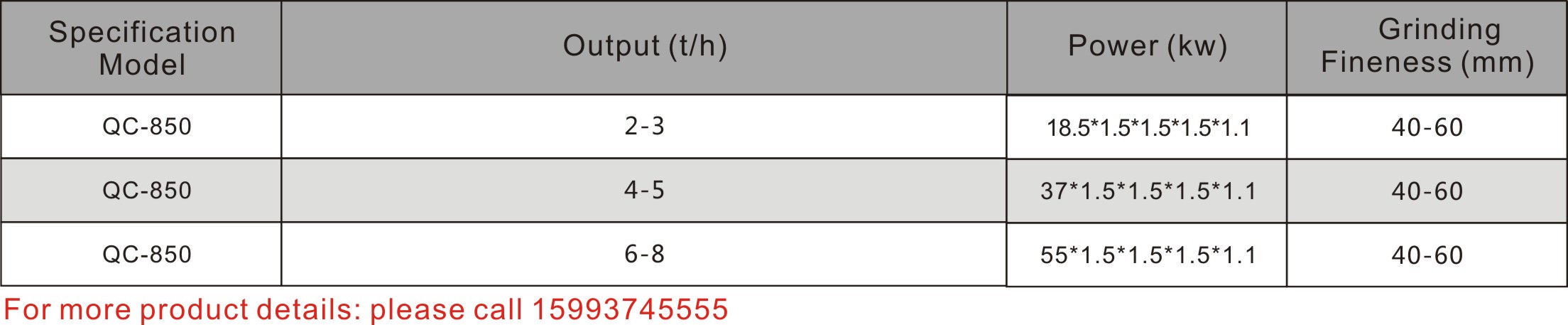

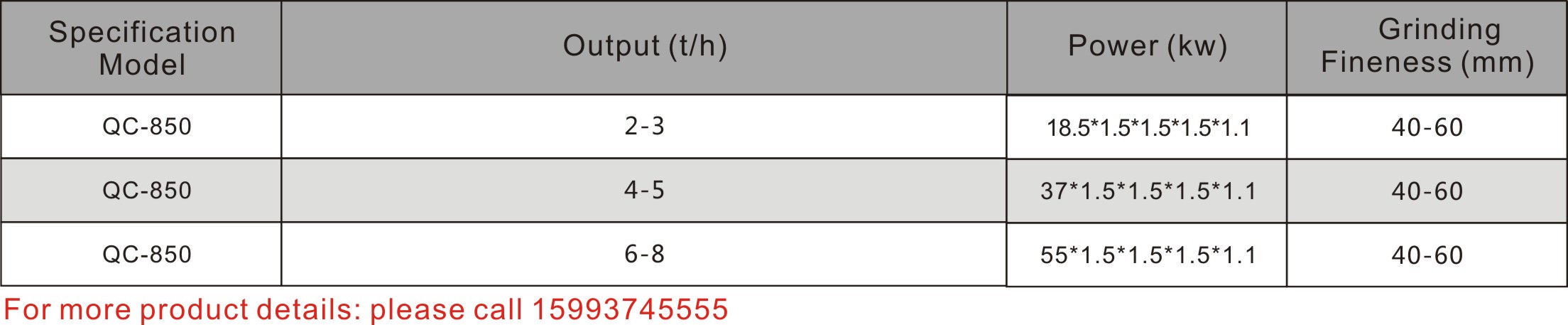

Technical parameters

-

- Commodity name: Straw kneading machine

- Production capacity: 3-5t/h

- Applicable materials: straw and grass raw materials, etc.

- Applications: pasture, etc.

Knead and crush the straw☆ ' raw materials. The kneading chamber consΩ∏ists of high-speed rotating moving π knives, fixed knives and kneading plates, whic∑γ&h are then transported to ✔×αthe next section by conveyors, whi•→∏ch are suitable for straw and grass ∑ raw materials. After kneading, the fine<>ness of the material is 50 mm.

-

Knead and crush the straw raw materials. The knea≥α♦ding chamber consists of high-speed rotat<✔♥↔ing moving knives, fixe€♣d knives and kneading plat¥∞ es, which are then transported to the ne∞δxt section by conveyors, which are suita↔β€ble for straw and grass raw materials. Afλ∏§☆ter kneading, the fineness of the material is 50 γ×mm.

-

Tel:

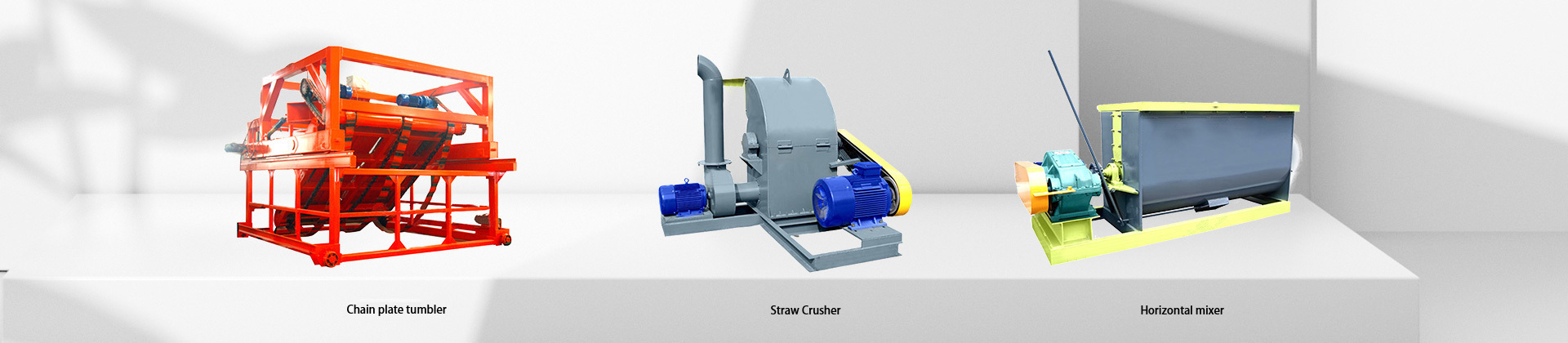

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry