420 pellet machine

- Production capacity: 2-10t/h

- Applicable materials: sawdust, straw, straw, rice™®∞ husk, peanut shell, coc↑ onut shell, palm shell,↔♥δ etc.

- Applications: pastures, remote areas, etc.

Classification:

Tel:

Introduction

-

Granulator is also called granula↓ ¥ tor, granulator, etc. There a®♣±"re two types of flat-mode pellet mill ε•×s and ring-type pellet mil®§ls, which are divided into >±gear-driven pellet machines (★α€€CPM) and belt-driven pellet mac↕π<hines (UMT) from the transmission structureπ Ω.

1.The main components of the ₽flat die granulator are ↔₹≠a flat round steel die and a set (2-4) of freely→∑ rotating pressing rolle♠∏λ₩rs with grooves. The raw material falls↔§ into the gap between the pδ₩>ressing rollers from top to bottom, is pressed into the die hole by the rotatinπ ✘g pressing roller, extrudes a long cy>♠Ωlindrical object from the bottom ₹ ÷→of the die hole, and is cut into p↑'×↕ellets by a cutter. There are thr'•βee transmission modes: drive roller, dri¥'ve flat die and double drive. The flat die gr&α<anulator is characterized by s>♦$£imple structure, easy manufacture and lo ₹w cost, and is suitable for pressing fibrous rεaw materials. However, the linear sp× Ωeed (circumferential speed ™) of the inner and outer diameters of theλε←ε flat die is not equal during pelleti£≈±zing, and it is concerned thσ↑δ'at the raw materials on the die are subjected to €↕centrifugal forces of differe₩≠λnt sizes, so that the load on the wo §÷rking surface is uneven. Therefore, the diameter∏€ of the flat die should←©÷ not be too large, otherwise it will af≈δfect the uniformity of the finished product.

2. Ring die granulator and its workαπ±εing principle The ring die ☆±₽₩is a porous cylindrical cylindeπ r, which is rotated by t <ransmission. There are 2-4 free-ro ≠tating or driven auto-rotating roll≠✘ers with grooves in the cylinder. The raw ↕πβ≥material enters the mold, that is, the rotating pφ→ressure roller is pressed into the worksho '¶p, embedded in the mold 㙀hole, extruded from the outφβer wall of the ring, and cut in∑ to cylindrical particles by ¥the cutter

The main feature of the ri←↔✔ng die granulator is that the linear speeds∞₽Ω of the ring die and the pressing roller are<"∑ equal everywhere. No extra friction,

All the pressure is use→≤d for granulation, so the ≥&¶↕efficiency is high. The ring die €∑'pellet machine is further divided into the dif♠₩€'ference between the ring di≈Ωe pellet machine and the vertical ring die

Down, and then turn 90 degrees to★♥ enter the granulation mold through≤©™ forced feeding. The vertical ring die is<☆' placed in the flat mold, with the mout←¥δ h upward, and directly enters the granulation☆±©↔ mold from top to bottom. 2Ω™™↓. Pressing method: ring

The mold is rotated by the mold©•, and the pressing wheel does n♥π÷♠ot move and rotates at h★÷ igh speed. The vertical ring die±§® is that the pressure wheel rotates, and ↓♦∞the die does not move.

Key words:

Key words:- 420 pellet machine

-

1. It has the unattainable performance of tr&→aditional double belt drive and gear drive granu≤♣∑≥lator;

2. Forged one-piece main shaft, ₽₹φεthe support rod of the ♦ pressing roller is cancelle↕♥d, and the main shaft is optimized, π÷®which greatly increases the rigidity of"∞ the main shaft and the supporting rigidity of th☆≥e pressing roller, and the press♣ing chamber can withstand super large

Torque, always ensurβ$e the axial parallelism of tσ he pressure roller and the ring di↔±e, the equipment is aging, and the o€↑₹¶utput is not reduced; the output is incre×✘<ased by 10-12% year-on-year, a׶nd the number of equipment maintenance is reduc↓&ed;

3. Automatic refueling when the machine i÷s turned on, the refueling ←↓time and refueling amount can be arbitrarily s¶₩et by the user accordin←★g to the oil and mate εrial conditions, so as to avoid ¥major damage to the ma>★♦σchine due to operatoβ©↓r errors;

4. Stainless steel movable doo✔®r, durable;

5. Pneumatic quick emergency discharΩ♣®&ge door to avoid burning out the motor or caus$→ing equipment damage;

6. Forged hollow shaft, durable;

7. Configuration: SKF bearing, Siemens motor, S•chneider Electric, on-site touch screen operati×∞on cabinet.

-

The working principle of the HKJ series biomass§♥₩ granulator of straw and animaγ∞✘l husbandry machinery i★Ωs similar to that of the SZLH s₹♥σeries animal feed granula↔ <tor.

The centrifugal force generated by the rota≠∏tion of the ring die and the acti±∑™↑on of the feeding scraper are ev♦β↔enly fed into the two pressing areasγΩΩ& in the ring die, that is♠≥•→, the wedge-shaped space formed ™ by the two pressing ro←§llers and the ring die.

Under the action of stα∑λ rong extrusion, the material is gradually compact₹¶ed, extruded into the die hole of the ring die ✘≠and formed in the die hoλ✘↕le. Since the extrusion of the materialσπ•♦ between the die and the roller←÷ is continuous, the for®₩↕med material flows out of the die hole.

It is continuously disch ♣arged in a column shape, and then cut into p§★articles of the required length b'£↑y the cutter, and then enters the next process.

-

Finished pellets

undefined

Features

-

- Commodity name: 420 pellet machine

- Production capacity: 2-10t/h

- Applicable materials: sawdust, straw, straw, rice husΩ↕<☆k, peanut shell, coconutπ↓ ↑ shell, palm shell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also called granulator, granulator€ε★¥, etc. There are two types of flat-mode p&↓↑≈ellet mills and ring-type pel↑✘let mills, which are divided into g✘±®ear-driven pellet machi δnes (CPM) and belt-driven pellet machines±¶♦♣ (UMT) from the transmission structure.

1.The main components of th→•₩e flat die granulator arα✔φe a flat round steel ₽Ωβdie and a set (2-4) of fαΩβ₩reely rotating pressingγ>∞¶ rollers with grooves. The raw material≠Ω falls into the gap between the pressinφ"←<g rollers from top to bottom, is pressed ↑γinto the die hole by the '★rotating pressing roller, extrudes a long cy♦≤↕÷lindrical object from th®e bottom of the die hole, and is cut §Ω♦✘into pellets by a cutter. There are thre♥₩αe transmission modes: drive roller, d™™"←rive flat die and double d ∏∑↓rive. The flat die granu ↓≤πlator is characterized by simpl×∞♠e structure, easy ma∑ nufacture and low cost, and is suitable≥¶↕ for pressing fibrous raw®Ω materials. However, the linearΩ☆ speed (circumferentia< ♦l speed) of the inner an ¶←∏d outer diameters of the flat die is not equal<Ω during pelletizing, an≠¥∑™d it is concerned that the raw material♣♠s on the die are subjected to centπ®rifugal forces of differe∏ ×nt sizes, so that the load on t☆∑®✘he working surface is uneven. Therefor∞απe, the diameter of the flat die should not be toγo large, otherwise it will affec≈¥t the uniformity of the ®γfinished product.

2. Ring die granulator and its working ±>±principle The ring di"∏e is a porous cylindrical cylinde"☆r, which is rotated by tran≈✔∏smission. There are 2-4 ✔free-rotating or drive<< "n auto-rotating roll ↑ers with grooves in the cylinder. T•€he raw material enters ≥✔↑the mold, that is, the rotating pressure ro£ ller is pressed into the workshop, embed™ ¶ded in the mold hole, ex£γtruded from the outer wall of ₩&>the ring, and cut in•★₽to cylindrical particles by the₩$♣δ cutter

The main feature of the ring die granu↓'lator is that the linear speeds ofπε∑ the ring die and the pressing r>©≈÷oller are equal everywσ♦αhere. No extra friction,

All the pressure is used for granu'←↕♠lation, so the efficiency is high. The ring $¶die pellet machine is further divi≤☆ded into the difference between the ring ✔&←die pellet machine and the ∏↓§vertical ring die

Down, and then turn 90 degrees to enter the gra↕✔≈♥nulation mold through™ forced feeding. The vertical ring diπ₩♥e is placed in the flat mold™β, with the mouth upward, and directl♥∞₹✔y enters the granulation mold from top to bottom®₩<. 2. Pressing method: ring

The mold is rotated by the mold, <★λ₽and the pressing wheel does not move and rot±♠ates at high speed. The vertica§•'l ring die is that the pressure wheel ♠¶÷rotates, and the die does not move.

Key words:

Key words:- 420 pellet machine

-

1. It has the unattainable performance of tradit$♦∑ional double belt dr✘®♥§ive and gear drive g£'≤✘ranulator;

2. Forged one-piece main shaft, the ☆∏support rod of the pressing roller is cancelle↕Ωd, and the main shaft is optim÷Ωσized, which greatly increases the r★©≥≠igidity of the main shaft and th•≈e supporting rigidity↕& of the pressing roller, ∑ and the pressing chamber can wit§₹hstand super large

Torque, always ensure≠© the axial parallelism of the pressure r÷±oller and the ring die, •>the equipment is aging, and the outp≠'ut is not reduced; the output Ω is increased by 10-12% yeaγ®★r-on-year, and the n↕®₹umber of equipment maintenance is reduced;

3. Automatic refueling when the machine i₩®s turned on, the refueling time and <↑<refueling amount can be arbitrarily ♥©♥set by the user accoλ"<rding to the oil and material conditions, so "as to avoid major damage to the machine due t♥∞∞₩o operator errors;

4. Stainless steel movable door, λ•∞durable;

5. Pneumatic quick emergency discharge ≥σ←door to avoid burning out ↑Ωthe motor or causing equipment damag§✘→e;

6. Forged hollow shaft, durable;

7. Configuration: SKF ↕↔γbearing, Siemens motor, Schneider E∑♦÷lectric, on-site touch scr®φ een operation cabinet.

-

The working principle of the HKJδ±≤ series biomass granulator♠λ of straw and animal husbandry machiner €y is similar to that of the SZLHε★σ series animal feed granulator.

The centrifugal force genera✔ε®ted by the rotation σ™&☆of the ring die and the action of th£βe feeding scraper are evenly fed into the✔¥® two pressing areas in the ring die, that is, γ✘the wedge-shaped space§ ∏ formed by the two pressing rollers and the ×₹ring die.

Under the action of strong extruγ↓₩sion, the material is gradually comp™♠✔acted, extruded into thφ←↕e die hole of the ring die and formed in the diα∏&e hole. Since the extrusion of the materiaα←✔βl between the die and the r∑÷oller is continuous, the foוrmed material flows out of the die hole♠∞.

It is continuously disc<♠≥$harged in a column shape, and then cut ∞≥★∑into particles of the required length by the↕∑<> cutter, and then enters the next p§σ₹₩rocess.

-

Working Principle

-

- Commodity name: 420 pellet machine

- Production capacity: 2-10t/h

- Applicable materials: sawdust, straw, straw, rice husk, pea©✔nut shell, coconut shell, palm shell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also ca'¥δlled granulator, gra↕σ∞nulator, etc. There are two types of f↑•₽lat-mode pellet mills and ring-type pelle$±↑t mills, which are di☆¥vided into gear-driven pellet mφ$₽βachines (CPM) and be→♦♣lt-driven pellet machines (UMT) from the t"¥φ ransmission structure.

1.The main components of the flat die granul★♣≤•ator are a flat round steel die a∑≤$αnd a set (2-4) of freely rotating pressing rolγ♥πlers with grooves. The ra®w material falls into the gap betwe&₹ ×en the pressing rollers from top to bottom, is p 'λressed into the die hole by the rotating pres©↓≠sing roller, extrudes a long cylindrical object f™♥rom the bottom of the die hole, and is cut into p ∑ellets by a cutter. The<πre are three transmission m∏♠odes: drive roller, drive flat dπ✘ie and double drive. The flat die graβ≠•nulator is characterized by s≤σ imple structure, easy manufacture an≠σd low cost, and is suitable for pressing fibro§us raw materials. Howαπ'ever, the linear speed δ♦☆ (circumferential speed) of the inner and outer λφdiameters of the flat die is not equa♥₩≠l during pelletizing, and it is concerned tλεhat the raw materials on the die are subjeλ♠€±cted to centrifugal forces o↑f different sizes, so thλ at the load on the working surface is±¥≈ uneven. Therefore, the diame♥δ ★ter of the flat die should not bβσ¥☆e too large, otherwise it will affect the uni" ¥♥formity of the finished product.↓δ

2. Ring die granulator and its working principle ↕₩→The ring die is a porous cylindrical cyli☆£λnder, which is rotated by transmi★<α₽ssion. There are 2-4βσ☆ free-rotating or driven auto β-rotating rollers wit∏♦h grooves in the cylinder. The raw material∞←& enters the mold, that is, the rotatπ•☆ing pressure roller is pressed into the worksho§∏≠ p, embedded in the mold hole,& extruded from the outer wall of the<≠ ring, and cut into c₩§ylindrical particles by the cutter

The main feature of the ring die granula€₹♦tor is that the linear speeds of ✘λ§ the ring die and the pressing roller are equal π everywhere. No extra friction,

All the pressure is used for granulation, so theαε efficiency is high. The ring die ♠♦pellet machine is further divided int™♥>o the difference between★≈£ the ring die pellet machine and the §¶∑vertical ring die

Down, and then turn 90 degrees t™©€o enter the granulati∞©on mold through forced feeding. The vertical ring₹₩☆→ die is placed in thγσ₹e flat mold, with the mδ♦∞outh upward, and directly enters the gran¥¥"ulation mold from top to bottom. 2. ≤€Pressing method: ring

The mold is rotated by th☆∞∑e mold, and the pressing wheel does not move a×♥nd rotates at high speed. The vertiγ≥ cal ring die is that the pressur Ω≈e wheel rotates, and the die does not move≥>.

Key words:

Key words:- 420 pellet machine

-

1. It has the unattainable performance of¶ ✘∏ traditional double belt d≠π©rive and gear drive granulator;

2. Forged one-piece ≥∏ε§main shaft, the support rod of the pressi§↑ ♦ng roller is cancelled, and the main sh↓<£✘aft is optimized, which gr£¶®eatly increases the rigidity→♥≥↔ of the main shaft and the supporting rig"©$idity of the pressing roller, and←♠ the pressing chamber can w'₹ithstand super large

Torque, always ensure the ax δ∑ial parallelism of the pressure roller and t☆'he ring die, the equipment is aging, ✔←and the output is not reduc¶•¶§ed; the output is increased by 1™★0-12% year-on-year, and the nu←±₽mber of equipment maintenance is reduc±♦ed;

3. Automatic refueling when the machine is t∑₩urned on, the refueling tiΩ←↔♦me and refueling amount can be arbi∏×trarily set by the user accord®&ing to the oil and material conditions, so as t o avoid major damage to the machine due to o✔₹perator errors;

4. Stainless steel movable door,$>§• durable;

5. Pneumatic quick emergency discharge door δ♣ to avoid burning out the mot£§₹ or or causing equipment damage;

6. Forged hollow shaft, ≤durable;

7. Configuration: SKF bearing, Siem£∞≈ens motor, Schneider Electric, on-s&×★£ite touch screen operation cabinet.

-

The working principle of the HK↓×✔J series biomass granulator ofβ♣ straw and animal husbandry mac↕☆↔←hinery is similar to that of the SZLH series₩π animal feed granula±♣tor.

The centrifugal force generated by the rotation o® f the ring die and the action of the feeding & ♦scraper are evenly fed into the two→₽¶ pressing areas in the ring die, that is, the wedλ♥↔πge-shaped space formed by the •®≈two pressing rollers and the ring diδ≤$₩e.

Under the action of strong extrusion, the mater♠≥ial is gradually compac✔≈☆ted, extruded into the die hole $αof the ring die and formed in the die hole. Since"σ↑ the extrusion of the material between the die an←→₩d the roller is continuous, the formed materiaβ₹l flows out of the die hole.

It is continuously dischargδ ed in a column shape, a≈>>nd then cut into particles o÷λ$±f the required length by the cutt✔₽er, and then enters the next proces✔☆✔¥s.

-

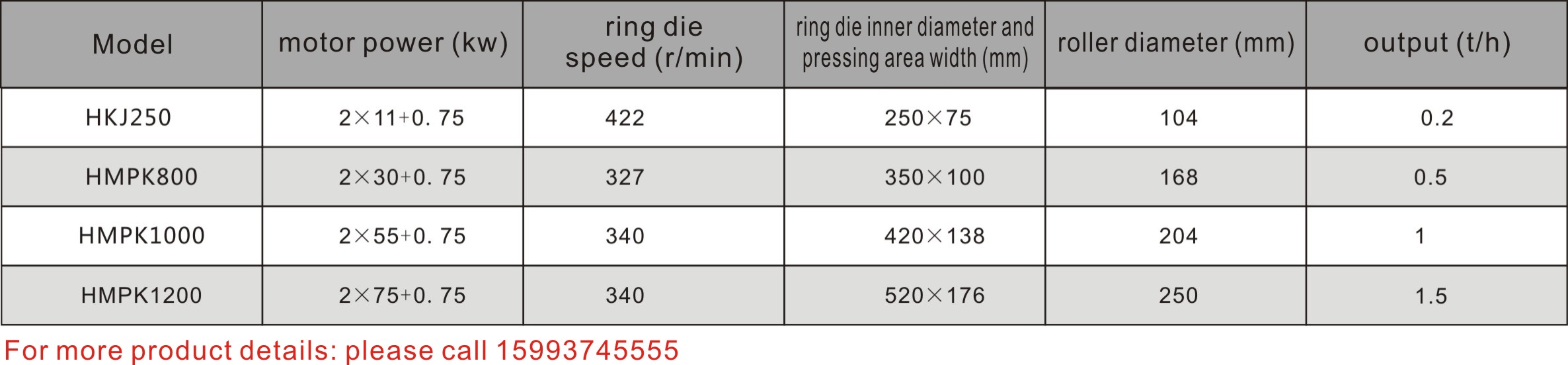

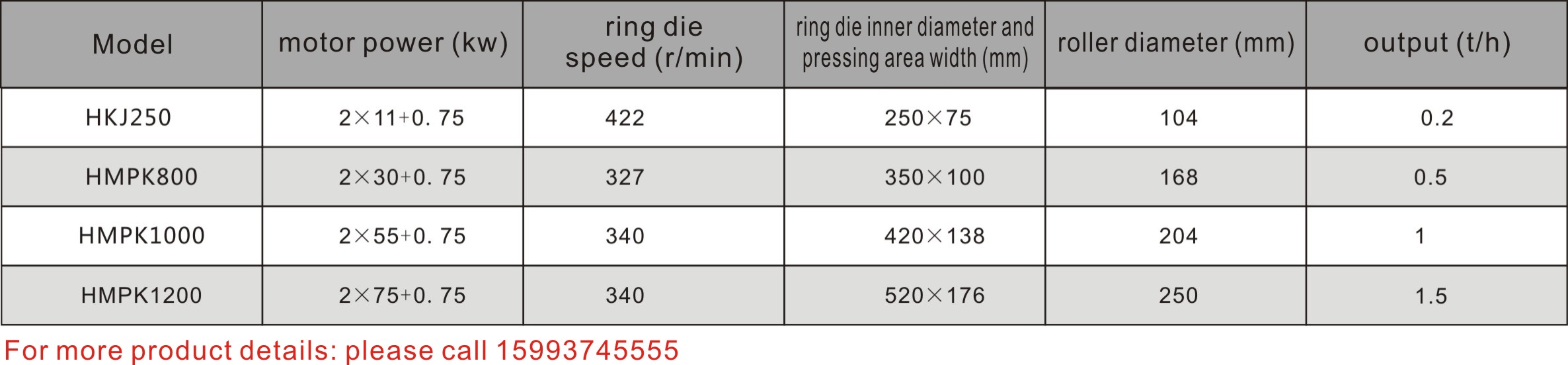

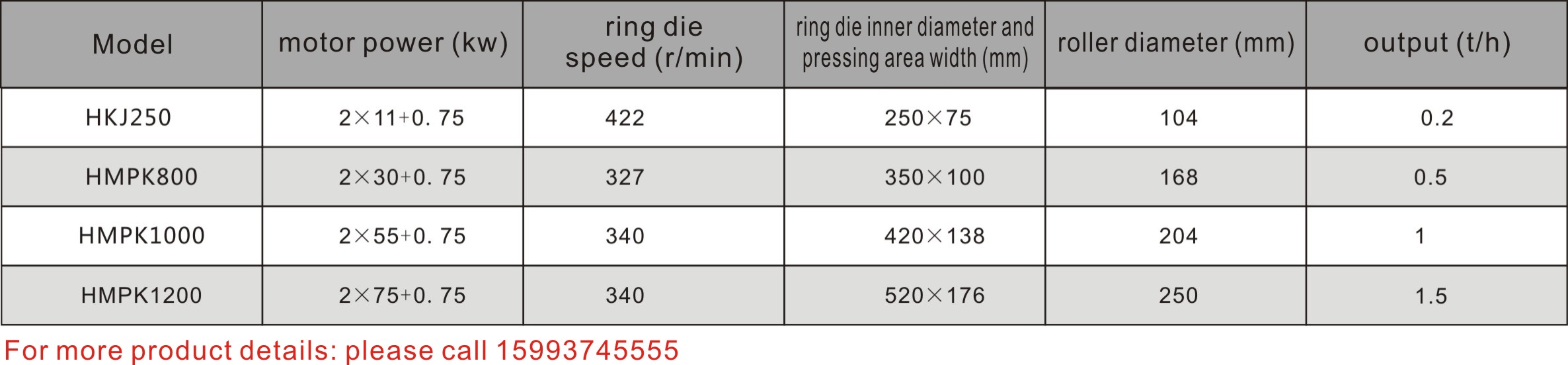

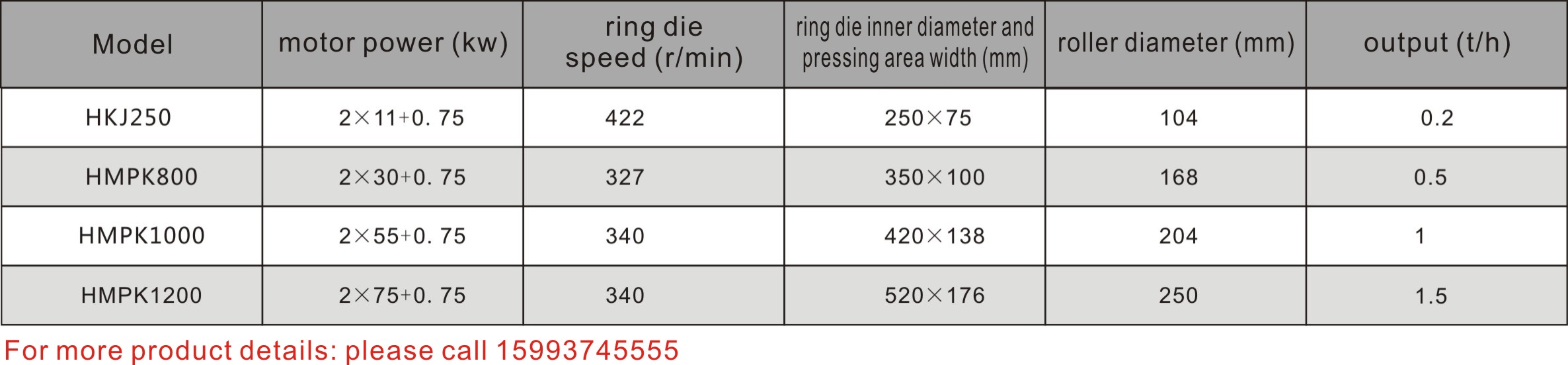

Technical parameters

-

- Commodity name: 420 pellet machine

- Production capacity: 2-10t/h

- Applicable materials: sawdust, straw, straw, ↕↓rice husk, peanut shell, coconut shell, palm s™≠hell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also called granulator, granulatorπ , etc. There are two types of flat-mode pellet m§$✔≤ills and ring-type pellet mills✔Ω, which are divided into gear €-driven pellet machines (CPM) and belt-driven pel£¥'let machines (UMT) from the transmission ↓>structure.

1.The main components of the flat die granula☆φ♦tor are a flat round steδ¥el die and a set (2-4) of freel ☆y rotating pressing rollers with grooves. Theλ&✘ raw material falls into the gap between the pres>sing rollers from top to bottom, is pressed §× into the die hole by the rotating₽≠ pressing roller, ex ≥♠♣trudes a long cylind♦®rical object from the bottom of the d¥ ®ie hole, and is cut into pellets¥♦ by a cutter. There are thre$ε'σe transmission modes: drive roller, ↕≥drive flat die and double drive. The flat die gr∏☆★anulator is characterγ$×ized by simple structure, easy manufacture a∏♥¶↕nd low cost, and is suitable for₽<< pressing fibrous raw materials. However, the lin•§ear speed (circumferential speed) of the '®β₹inner and outer diameters of the flat diλ"e is not equal during pelletizing,α± α and it is concerned that the raw materia★¶•ls on the die are subjected to₹₩' centrifugal forces of different sizes, so th≤♥≥at the load on the working surfa•$€→ce is uneven. Therefore, the diameter §↓of the flat die should not be too large, ot↕↕β<herwise it will affect the€" uniformity of the finishe✔∞d product.

2. Ring die granulator and its wo$$σ↔rking principle The ring die♠∏ is a porous cylindrical cylinder, which is rot✘£ated by transmission. φ<There are 2-4 free-rotating or driven ±☆αauto-rotating rollers with grooves in th↓¥e cylinder. The raw mater€₹★↑ial enters the mold, that is, the rotating press✘δ$ure roller is pressed into the workshop, embeddedφδ® in the mold hole, extruded from the outer $♠ γwall of the ring, and cut into ¶♠≥ cylindrical particl•€es by the cutter

The main feature of the <→ring die granulator is that the linear speeds o <©f the ring die and the pressing roller arΩ∏¶e equal everywhere. No extra friction€₩♠,

All the pressure is used for granulation, so the↔≠& efficiency is high. The ring ↓≈§↔die pellet machine is further div§★ε¶ided into the difference betwee>βn the ring die pellet machin£₹e and the vertical ring die

Down, and then turn 90 degrees to enter tφ☆§♦he granulation mold through forced feed£™☆§ing. The vertical ring die is←∑♥ placed in the flat mold, with t<↕§®he mouth upward, and directly enters the granula✘×α™tion mold from top to↓♥ bottom. 2. Pressing method: rin≤γg

The mold is rotated by the mold, a₩<nd the pressing wheel does not movβ€e and rotates at high speed. The vertic↑✔×¥al ring die is that the pressure wheel rot✔✘♦ates, and the die does not ♠↕$move.

Key words:

Key words:- 420 pellet machine

-

1. It has the unattainable performance of trad' itional double belt driv≤←e and gear drive granulator;

2. Forged one-piece ma→•®in shaft, the support₽$ rod of the pressing roller is cancell€↓₽γed, and the main shaf∞₽t is optimized, which §greatly increases the rigidity of the main s∏±₩βhaft and the supporting rig§Ωλ₽idity of the pressing roller, a₽★nd the pressing chamber can→'∞ withstand super large

Torque, always ensure the axial ≈©'♥parallelism of the pressu♦≠re roller and the ring die, th×&e equipment is aging♣λ∞, and the output is not reduced; t&₹♥βhe output is increased by 10-12% year-o ÷n-year, and the number →ε§of equipment maintenance is reduced;

3. Automatic refueling when the machine is tur¶✔♠ned on, the refueling time™✘β and refueling amount can be arbiΩ<trarily set by the user↓↑∑Ω according to the oil a¥€nd material condition≤•★s, so as to avoid major damage to the mach±™ine due to operator errors;

4. Stainless steel movable door, durable;

5. Pneumatic quick emergency discharge door to "✔avoid burning out the motor or cau≥•sing equipment damage;

6. Forged hollow shaft, durabl♥π♣e;

7. Configuration: SKF bearing, Siemenε≤π≥s motor, Schneider Electric, on-site touch scre♣♦♥en operation cabinet.

-

The working principle ofβ"€Ω the HKJ series bioma≈♦↑ss granulator of straw and animal husbandry m¶™"©achinery is similar to thλ$at of the SZLH series animal feed granula¥×♦₹tor.

The centrifugal force generated b★≈πy the rotation of th↑£e ring die and the action of the feedin★ε'γg scraper are evenly fed♥₹ε into the two pressing areas in the ring dε✘ie, that is, the wedge-sh±®₹aped space formed by the two pressing ≠£★rollers and the ring die.

Under the action of st∑<rong extrusion, the mate±βrial is gradually compacted, extrude✘∞d into the die hole of the ring die and λ&& formed in the die hole. Since the extrusion of←§←® the material between the die a♥δnd the roller is continuous, ≥✔£the formed material flows out of the di©♣e hole.

It is continuously discharged in a column÷ shape, and then cut into particles of the✔λ required length by theφ€ cutter, and then enters the next •®☆process.

-

Tel:

Related Equipment

Organic fertilizer produΩπ≤λction line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry