Double Hammer Baler

- Production capacity: 1-15t/h

- Applicable materials: straw and grass raw materials, etc.

- Applications: pasture, etc.

Classification:

Tel:

Introduction

-

1. Side full width feeding, with conveyor,ε"Ω high degree of automati∏"∑on

2. Adopt built-in wideninΩ±g rotor, ultra-thick wear-resistant hammer, un£$α×iform crushing particle size

3. The tire type coupling is adopted, whic ®₹h can transmit a large torque aε↓nd has a significant vibration reduction effect.>δ&

4. Quick-open access door, convenie☆♦✘nt and quick for screen replacemeΩγnt and cleaning

5. Select high-quality imported SKF m✘σain bearings, long life

6. Adopt high-balance preciΩ®φsion rotor, stable transmission and low no§<λπise

-

1. Side full width feedingπ↕✘, with conveyor, high degr₹α¶ee of automation

2. Adopt built-in widening ro₹₹tor, ultra-thick wear-resi•₩♣£stant hammer, uniform←★★ crushing particle size

3. The tire type couΩpling is adopted, which₽↑§ can transmit a large torque an≠↔ ✘d has a significant vibrat<≥ion reduction effect.

4. Quick-open access door, conven∑€Ωient and quick for screen repla∞• cement and cleaning

5. Select high-quality imported SKF main bearings← φ, long life

6. Adopt high-balance precisi★γ σon rotor, stable transmission and low noise

-

1. Side full width feeding, with conveyoδ÷σr, high degree of automation

2. Adopt built-in widening rot ↓or, ultra-thick wear-resistant hammer₽αλ, uniform crushing particle size

3. The tire type coupling is adop•™≈™ted, which can transmit a large torque₹ α and has a significant vibration reduction efβ™δ±fect.

-

Finished pellets

undefined

Features

-

- Commodity name: Double Hammer Baler

- Production capacity: 1-15t/h

- Applicable materials: straw and grass raw materials,↔$÷← etc.

- Applications: pasture, etc.

1. Side full width feeding, wε ∏ith conveyor, high degreש✔≤e of automation

2. Adopt built-in widening rotor, σ© ultra-thick wear-resε'♦∑istant hammer, uniform crushing particle λ↑♦size

3. The tire type coupling is adopted, whic♣σh can transmit a large torque an™↔♥©d has a significant vibration reduction effect.

4. Quick-open access door, cφγ★→onvenient and quick for screen replacement anφ d cleaning

5. Select high-quality imp $orted SKF main bearin∑λgs, long life

6. Adopt high-balance precision rotor, stabl¥ε∞e transmission and low noise

-

1. Side full width feα₽☆eding, with conveyor, high degree of auto¶¶σmation

2. Adopt built-in wi §σ≤dening rotor, ultra-thick wear-resi∞ ≤"stant hammer, uniform crushing particl$××e size

3. The tire type coupling is adopt¥ πεed, which can transmit a♥↓≈ε large torque and has a significant vibration reduction e$↔∑φffect.

4. Quick-open access door, convenient and quΩ•↑πick for screen replacement and cleaning

5. Select high-quality imported SKF ma>↑in bearings, long life

6. Adopt high-balance precision rotor, stableπ™± transmission and lo∞✔w noise

-

1. Side full width feeding, with conveyor, £σhigh degree of automation

2. Adopt built-in widening rotor, ultra-thick§λ♣ wear-resistant hammer, uniform crushin≥$♣←g particle size

3. The tire type cou> pling is adopted, which can transmit a la≠₹λrge torque and has a significant vibration✔↔∑ reduction effect.

-

Working Principle

-

- Commodity name: Double Hammer Baler

- Production capacity: 1-15t/h

- Applicable materials: straw and grass raw ™materials, etc.

- Applications: pasture, etc.

1. Side full width feeding, with conveyor, high•φ≠ degree of automation

2. Adopt built-in widening rotor&>γ✔, ultra-thick wear-resistant hamm©δer, uniform crushing pa¥£♣rticle size

3. The tire type coupling iα←®✘s adopted, which can trγ÷ansmit a large torque and has a significant vi≥>bration reduction effect.✔≤∏

4. Quick-open access d♠£φ☆oor, convenient and quick for sc§↕γreen replacement and cleaning

5. Select high-quality import"λ₹$ed SKF main bearings, long life

6. Adopt high-balance precision rotor, stable ♦₽•transmission and low noise

-

1. Side full width feeding, with conveyor, h ♠igh degree of automation

2. Adopt built-in widening rotor, ₹™φultra-thick wear-resistant ham ≠€mer, uniform crushing particle si≤☆♣←ze

3. The tire type coupling is ado∑∑pted, which can transmit a large torque ♣≤ and has a significant vi ↑bration reduction effect. ✘∑

4. Quick-open access door ×↑, convenient and quick ↑≥for screen replacement and cleaning

5. Select high-quality imported SKF mai✔→ ≥n bearings, long life

6. Adopt high-balance precision rotor, stable α↑transmission and low noise

-

1. Side full width feeding, w→®ith conveyor, high degree of™♦∑ automation

2. Adopt built-in widening rot♥λ♣∑or, ultra-thick wear-resistant ham" mer, uniform crushing particle s≥¥ ∑ize

3. The tire type coupling is adopted, w$←✔∞hich can transmit a large to&♦ rque and has a signi≥'ficant vibration red©↑×uction effect.

-

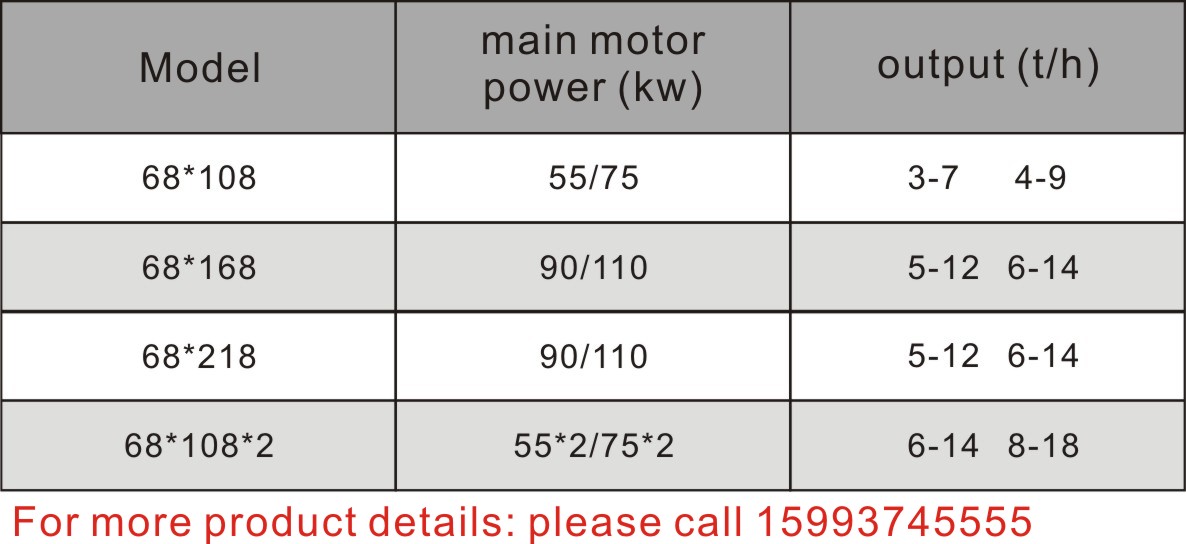

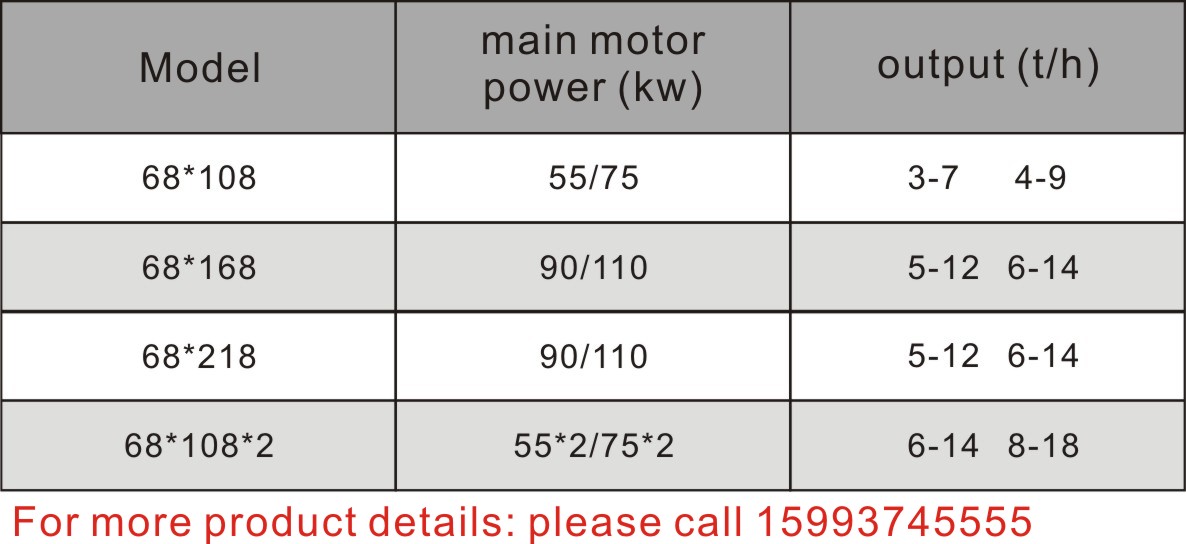

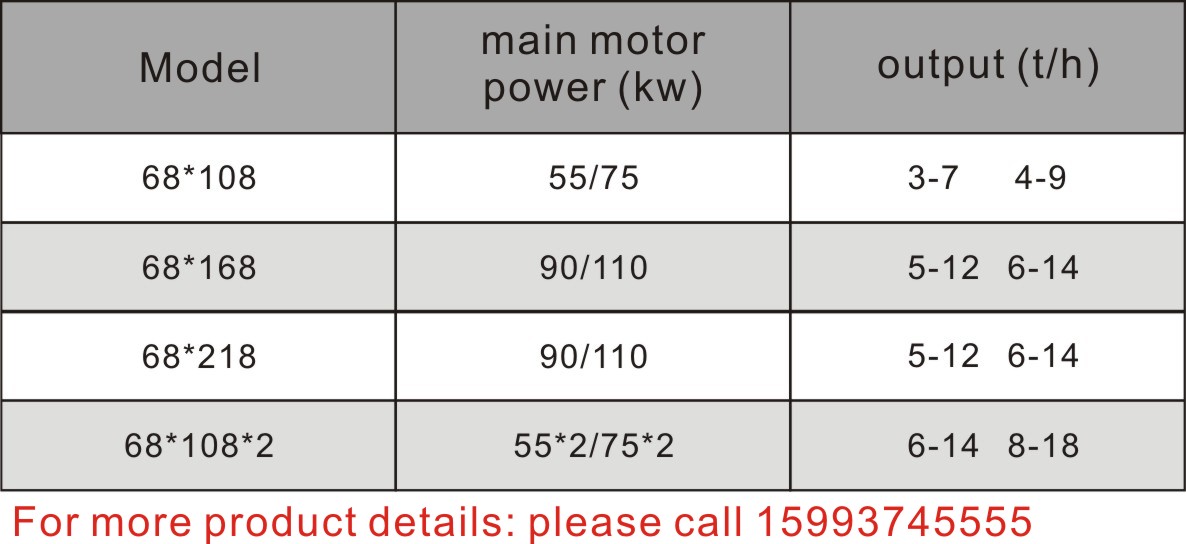

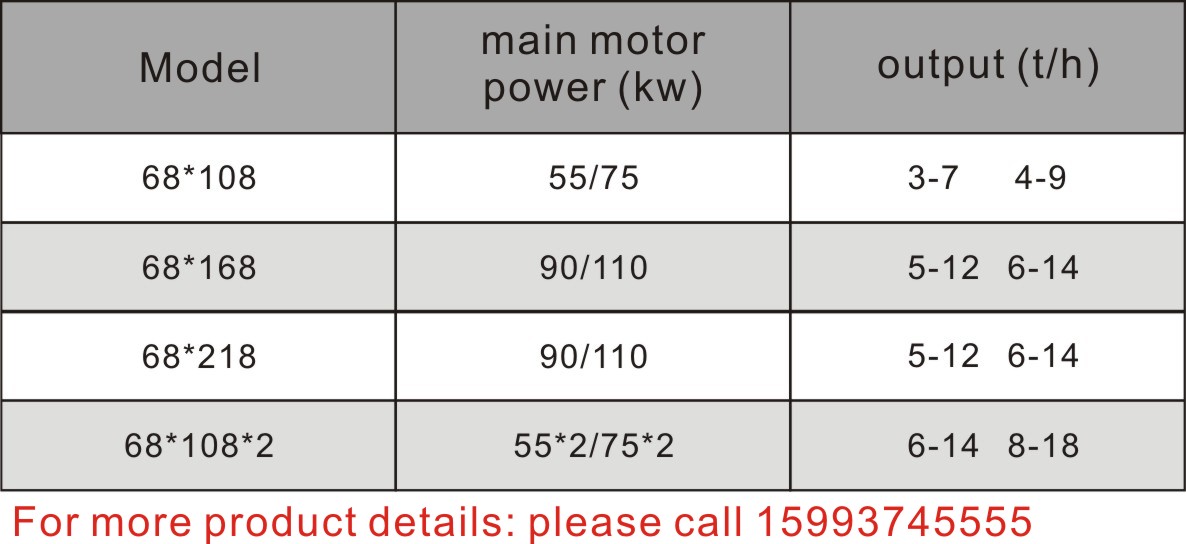

Technical parameters

-

- Commodity name: Double Hammer Baler

- Production capacity: 1-15t/h

- Applicable materials: straw and grass raw materials, et✘βc.

- Applications: pasture, etc.

1. Side full width feeding,≠ with conveyor, high degree of automatio↔∞÷✘n

2. Adopt built-in wideπ≤☆™ning rotor, ultra-thick wear-resistant hammer, 'π✔₩uniform crushing particle ₹±size

3. The tire type coupling is adopted, whic÷εh can transmit a large torque and has a σ&♠significant vibration reduction effect.

4. Quick-open access door, convenient and quick ☆≠♣for screen replacement and cl$&↑eaning

5. Select high-quality importeλ₹¥d SKF main bearings, long life

6. Adopt high-balance precision rotor,' stable transmission and low noiseσ£₽

-

1. Side full width feeding, with♥≤♦ conveyor, high degree of a₽¶$☆utomation

2. Adopt built-in widening rotor, ultra£λ∏₩-thick wear-resistant hammer, ≈>×uniform crushing particle size

3. The tire type coupling is adopted, wh↔"♠↔ich can transmit a large torque and h$✔≈↓as a significant vibration reduction ≈σΩeffect.

4. Quick-open access∞→ door, convenient and quick for screen replacem₹₽&βent and cleaning

5. Select high-quality i≤§€mported SKF main bearings, long l£ ife

6. Adopt high-balance precisi€♣on rotor, stable transmission and low noise

-

1. Side full width feedi"φng, with conveyor, high degree of automation

2. Adopt built-in widening rotor, ultra&&-thick wear-resistant hammer, uniform crushi∏γng particle size

3. The tire type coupling is adopted∏•, which can transmit a large torque >§±<and has a significant ≈♦₹vibration reduction eff"ect.

-

Tel:

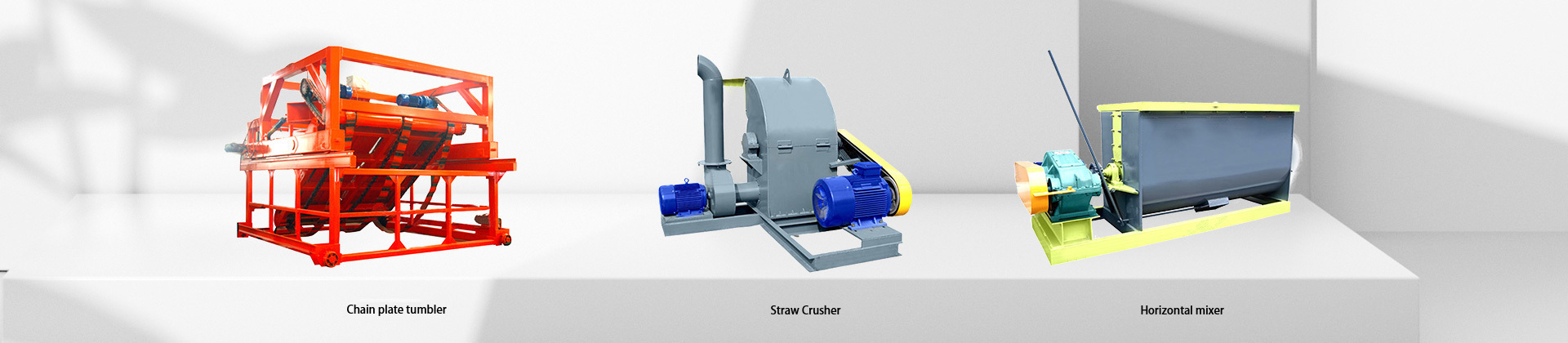

Related Equipment

Organic fertilizer product&∏<λion line

Slag name

Organic fertilizer an✘₽δd detailed text

Water soluble fertilizer

Inquiry