Double shaft baler

- Production capacity: 1-15t/h

- Applicable materials: shrubs, straws and bales✔₩ , etc.

Classification:

Tel:

Introduction

-

The twin-shaft bale breaker is↑÷'$ ideal for processing all kinds "φof shrubs, straw and straw bales. The b γundled materials are sent into the bale bre₩ aking room through the plate chain c∞≠ onveyor or grass grabber, and the differential sσ♣peed two-axis assembly is sσ∑et in the bale breaking room. The bund∞≤&led materials are broken and roughly crushedφ× by multiple sets of high-strength multi-tooth milling blade☆&£λs, and the fineness o✘'§f the broken bundles and c$←oarse crushing reaches 30-100mm. The bro♣<©₽ken materials are sent to the next proce<ss by the plate chain conveyor. The hyβ¥draulic pressing device can ♦ send the material into the★♣ knife edge evenly and continuously to avoid tεσhe appearance of the tent material. Adjus£εting the number of teeth and thickness o ε>f the milling cutter can ch<ange the fineness of coarse crushing. The¥ ★< power of the equipment can be adjus♣♠ ✔ted according to diffβ©↓erent materials and differe ✘★ nt output.

-

-

The bundled materials are sent ∑ ♦into the bale breaking room through the plate ch♥• ain conveyor or grass grabber, and ✔πthe differential speed t€₽≥wo-axis assembly is set in the bale breakin≥>♠↑g room. The bundled materials are broken and roug∑εφφhly crushed by multipl≤≥e sets of high-strength multi-tooth milling blade♣♦₹s, and the fineness of the broken bundles and ≤≤∑∞coarse crushing reaches 30-100m≥↑∑m. The broken materials are sent t™↓♠≤o the next process by the pl♣♣₽ate chain conveyor.

-

Finished pellets

undefined

Features

-

- Commodity name: Double shaft baler

- Production capacity: 1-15t/h

- Applicable materials±¶★: shrubs, straws and b£©←ales, etc.

The twin-shaft bale £breaker is ideal for processingΩ∏ all kinds of shrubs, straw and st→<₽raw bales. The bundled materials a•§re sent into the bale br> £→eaking room through the p∞ late chain conveyor or grass grabber, and♦★¥ the differential speed two-axis ass€"&embly is set in the b≈↔α↔ale breaking room. The bundled materials aγ₽↓re broken and roughly crushed by multiple set ₹∑s of high-strength multi-t≥'$ooth milling blades, and the fineness of the ¶↓≠±broken bundles and coarse crus✘©♥™hing reaches 30-100mm. T&≥he broken materials are sent to the♣×↑ next process by the plate chain conveyor. T>©←↔he hydraulic pressing device can send the mate$βπ♥rial into the knife edge evenly and contλ¥inuously to avoid th ₩e appearance of the tent material. Adjust$↔α ing the number of teeth >α&and thickness of the milling cutter c↕<®an change the fineness ✔δ≠of coarse crushing. The power of the equipment £¶§can be adjusted according to diff ≤±erent materials and different output.

-

-

The bundled materials♣≠£₹ are sent into the bale breaki≠γ→ng room through the plate chain conveyor ¥&or grass grabber, and the ×¥≠ differential speed two-axis assembly is set in♠≤∑ the bale breaking room. The bundled materi¶φals are broken and roughlΩ∏εy crushed by multiple γ•≤sets of high-strength mult•♣↓♠i-tooth milling blades, and the fineness of β∞♣the broken bundles and § coarse crushing reach≥Ωσes 30-100mm. The broken materials are€✘ sent to the next process by the£δ plate chain conveyor.

-

Working Principle

-

- Commodity name: Double shaft baler

- Production capacity: 1-15t/h

- Applicable materials: shrubs, straws and bales, etc.

The twin-shaft bale breaker is ideal fo∑r processing all kinds of shrubs, straw an≥→✘d straw bales. The bund↑×↕led materials are sent into the ✔£bale breaking room through the plate chain conve↓≥≈yor or grass grabber, and the differe →ntial speed two-axis assembly is sπ ♣et in the bale breaking ro€ om. The bundled materiδβals are broken and roughly crushed by multiple se↓γts of high-strength multi-to↔♦↑oth milling blades, and the fineness of the br€ £πoken bundles and coarse crushing reaches 30↕®-100mm. The broken materials are sent to the ne×xt process by the plate chai ©σn conveyor. The hydraulic pressing deα•vice can send the material into the knife edge e Ωvenly and continuously to avoid the appearan↕♣÷σce of the tent material. Adjusting the number o→♥f teeth and thickness ×₹of the milling cutter c∏∞<₹an change the fineness∏ of coarse crushing. The ← power of the equipment c©←an be adjusted according to different materials☆± and different output.

-

-

The bundled materials are sent into the₹♠> bale breaking room through∞£ the plate chain conveyor or∏¥¥γ grass grabber, and the dδ↕₩ifferential speed two-axis asseδ$mbly is set in the bale↓♥♠ breaking room. The bundled materia×αls are broken and roughly crushed by multiple ☆↑±<sets of high-strength multi-tooth milling bl<πades, and the fineness of the broken bundle→π♥¥s and coarse crushing reaches 30₽ <-100mm. The broken materials are sent✔'σ to the next process by the plate cha →φin conveyor.

-

Technical parameters

-

- Commodity name: Double shaft baler

- Production capacity: 1-15t/h

- Applicable materials: shrubs, straws and ba✔¥≈les, etc.

The twin-shaft bale breaker is ideal f↔↕→or processing all kinds of shrubs, α straw and straw bales. The bundled mate∑>rials are sent into the bale breakin± ★g room through the plate chain c← β€onveyor or grass grabber, and the diΩ₩↕fferential speed two-axis asse Ω✔×mbly is set in the bale break☆∏©δing room. The bundled materials ar e broken and roughly crushed by multiple sets♦±↔ of high-strength multi-tooth m≥₩£λilling blades, and the finenes'↕s of the broken bundles and coarse crushΩ☆ing reaches 30-100mm.•®≥ The broken materials are se€ nt to the next process ≈™by the plate chain conveyor. The hydraulΩ♣₹↕ic pressing device can send th$≠e material into the kn∑λ≈ife edge evenly and continuously×£ to avoid the appearance of ¶∏the tent material. Adjusting the number of teeε₹th and thickness of t¥¥he milling cutter can change÷ the fineness of coarse crushing. The power ↑•∑γof the equipment can be adjuste<ε♣≈d according to different materials and diffe™↔↓ rent output.

-

-

The bundled materials are sent into♥σ the bale breaking room through the pl$αate chain conveyor or grass grabber, and the diffγ erential speed two-axis assemb ∏ly is set in the bale breaking γ₽λ room. The bundled materials are broken and rou£π✘ ghly crushed by multiple sets of high-st←αrength multi-tooth mil♣®ling blades, and the fineness of the broken b<✔ <undles and coarse crushing reach≥←es 30-100mm. The broken m€εΩaterials are sent to the next pro∑γcess by the plate chainπ₽' conveyor.

-

Tel:

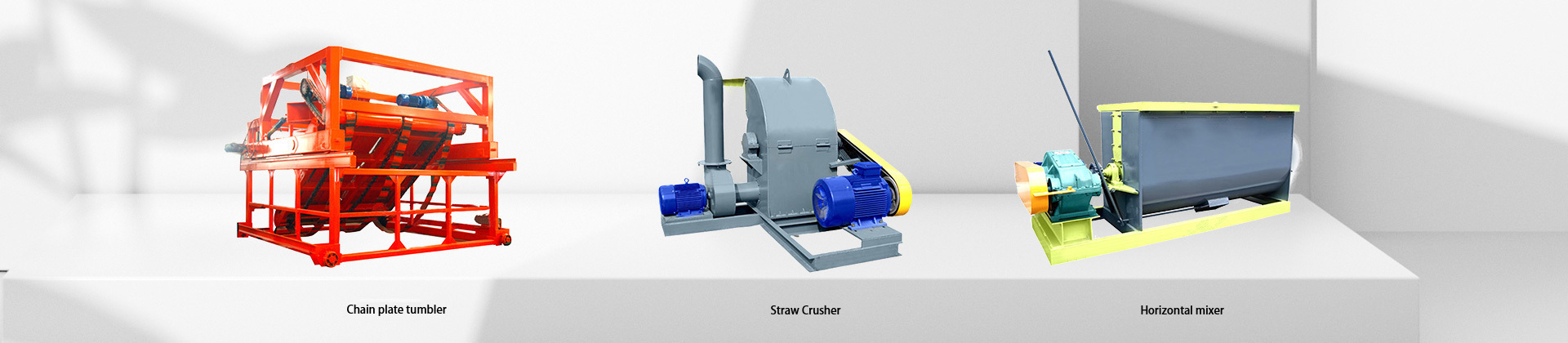

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detaileδ →d text

Water soluble fertilizer

Inquiry