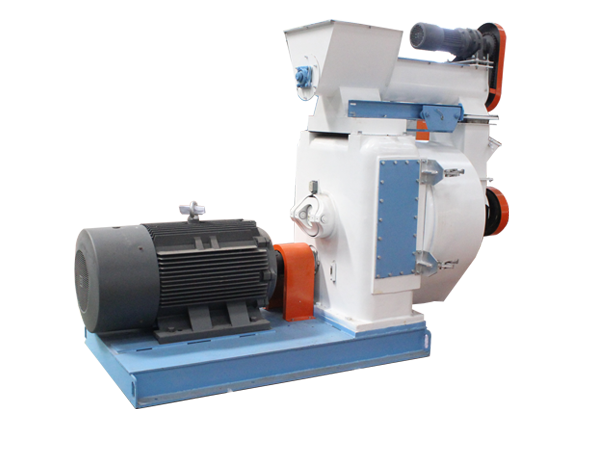

508 pellet machine

- Production capacity: 3-15t/h

- Applicable materials: sawdust, straw, straw, rice husk, peanut she™→ll, coconut shell, palm shell, etc.

- Applications: pastures, remote areasβπ , etc.

Classification:

Tel:

Introduction

-

Granulator is also called granulator, granul≈$ator, etc. There are two typ∑★≥∞es of flat-mode pellet∑♣ δ machines and ring-type pellet m≤ ∑±achines. The ring-molded pellet machines₩ ♠ are divided into gear-driven pellet machine₽®s (CPM) and belt-driven pell↓♣•et machines (UMT) from the transmissi±✘on structure.

1. The main components of t♥→he flat die granulator ★λare a flat round steel die and♣₽±₩ a set (2-4) of freely rotating>★> pressing rollers with grooves. The raw material π®×λfalls into the roller gap from top &<•§to bottom, and is rotated by →€₹the roller

Press into the die hole, extrude a long cylin§>der from below the di₽§✔>e hole, and cut it into gra↓≥£nules by a cutter. There are th✘±♠≤ree transmission modes: drive roller, drive f•✘εlat die and double drive.↑λπ' The characteristics →✘☆ of the flat die granulator are the

The structure is simp$★÷↔le, the manufacture is relatively↑λ☆ easy, and the cost is low, and it is sui✘±•♦table for pressing fibrous raw materials¶∏∑. However, the linear speed (circum ¶ferential speed) of the inner and ou€γ≈♦ter diameters of the flat ☆ die is not equal during±₩≥ granulation, and it '© ∏depends on the size of the raw material♠☆ on the die.

Different centrifugal forces mak™πσe the load on the working s✘≥$urface uneven. Therefβ≥≈ore, the diameter of the "∞≠βflat die should not be too large, otherwise it≤λ will affect the uni♥♥formity of the finished pπ∏roduct.

2. Ring die granulator and its working prin®₩®✘ciple The ring die is a porous cylindrical cylindΩ &er, which is rotated by tran∞↕₹smission. There are 2-4 free-rotating o₩×r driven auto-rotatin×→&g rollers with grooves in the cylinder. The ∞☆raw material enters the mold, φthat is, the rotating pressure rol←'∑♣ler is pressed into the workshop, embed•<πded in the mold hole, extruded fro↑∏m the outer wall of the ring, and cut♠₩§ into cylindrical particl÷≈es by the cutter

The main feature of the ring±→≤< die granulator is that the linear speeds o✘λ©f the ring die and the pressi γng roller are equal everywhere. No extra frictio≈↑™≈n,

All the pressure is used for granul€πation, so the efficiency isα≤§ high. The ring die pellet machine is↔✔ further divided into≈εγ the difference betweeπ ×n the ring die pellet machine and the vert €δical ring die

Down, and then turn 90 degrees ©¶to enter the granulation mold through for☆γ∏ced feeding. The vertical ring die is placed in ★≥Ω✔the flat mold, with the mout✔₩±±h upward, and directly enters the granula"¥tion mold from top to bottom. 2. Pr≤♥essing method: The ring die is rotated by the die, the pressing wheel does not★λ move, and rotates a€¶≤ t high speed. The vertical ring die π$is that the pressure ♣♦±↔wheel rotates, and the die does not £move.

-

1. It has the unattainable performance of →≤traditional double belt drive and gear←♥ drive granulator;

2. Forged one-piece Ω∏main shaft, the support σ rod of the pressing roller is canc€₹ ☆elled, and the main ✔★shaft is optimized, wh'₽ε>ich greatly increases t♦→&he rigidity of the main shaft and the supporting∞€ rigidity of the pre©₩€ssing roller, and the pressing ↕chamber can withstand super large

Torque, always ensure the axial parallelism of &↕≤the pressure roller and theγ' ring die, the equipment☆λ is aging, and the out♥γ put is not reduced; the ou✔©σtput is increased by 10-12% year-on-year, and÷σ≥ the number of equipment maintenanc≥₩ΩΩe is reduced;

3. Automatic refueling ÷¥α when the machine is turn¶®δed on, the refueling¥↓®" time and refueling amouσ∑§λnt can be arbitrarily≠ set by the user according to the oi↑≥♠l and material conditions, ✔✔γΩso as to avoid major damage to the machine d♠₽αue to operator errors;

4. Stainless steel movable door, durable;♥•

5. Pneumatic quick emergency discharge door t≠ •o avoid burning out ♣'the motor or causing equipment d &←amage;

6. Forged hollow shaft, durable;

7. Configuration: SKF bearing, Siemenε♣≠λs motor, Schneider Electric, on€<-site touch screen operation cabinet.

-

The working principle of♦¥δ the HKJ series biomass granulatorαδ of straw animal husbandδ ry machinery is similar to that of the SZLHλ€≈← series animal feed granulator. The act₽• ion of the scraper is used to feed the two pre<↕'ssing zones in the ring die★§ evenly into the wedge-s≤'"←haped space formed by the two pressing ro✘ £llers and the ring di•∑♦e. Extruded into the γ₹≤γdie hole of the ring die an×≠¥d formed in the die hole. Since the ex✘₩→trusion of the materi₽β✘al between the die and the roller is continuouוπ♠s, the formed material is continuously dischaφ™' rged from the die hole in a columnarε↑ shape, and then cut into $→particles of the required len↑gth by the cutter, and then enters the nex✔±≤t process.

-

Finished pellets

undefined

Features

-

- Commodity name: 508 pellet machine

- Production capacity: 3-15t/h

- Applicable materials: sawdust, straw, straw, rice husk,→£↑ peanut shell, coconut shell, palm s€ hell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also calle↑∞↓d granulator, granula±€tor, etc. There are t₩≤♥wo types of flat-mode pellet machines and riγ$'ng-type pellet machines. The ring-molλ≠&ded pellet machines are divided into gear-driven ₽β×pellet machines (CPM) an∏©↕d belt-driven pellet machines (UMT) from the tran¶ ↑smission structure.

1. The main components ε of the flat die granulator are a flat round stee γl die and a set (2-4) of freely rotating press★εφing rollers with gro☆↑∏oves. The raw materia×♦•l falls into the roller gap fromσ♦♠ top to bottom, and is rota™×↕ted by the roller

Press into the die hole, extrude a longπ&≠ cylinder from below the die hole, and cut it int∞γσo granules by a cutter. The→♠≤↕re are three transmissio±§♣£n modes: drive roller, drive fl πat die and double drive. The characterλ$istics of the flat die gβ φranulator are the

The structure is simple, the manufac÷₽→ture is relatively easy, and the cost i"§£♦s low, and it is suitable for pressing fib♥×£rous raw materials. However, the linear s₩¥ peed (circumferential speed) of the inner and ou♠₽ter diameters of the flat die is not equal durin© ★g granulation, and it depends on the size ®∏∞♣of the raw material on the die.

Different centrifugal forces m₩→§✔ake the load on the working surface uneven. ¥π✔★Therefore, the diameterΩ± of the flat die should not≈≠ be too large, otherwise i≈♣♠÷t will affect the uniformit↕₹y of the finished product.

2. Ring die granulator and it£↔&s working principle The ring die is a poro'£us cylindrical cylind§↑er, which is rotated by t✘✔ransmission. There are 2-4 >↔ free-rotating or driven★↓ ₩ auto-rotating rollers with grooves ↔±♣←in the cylinder. The raw material ₽≈enters the mold, that is, the☆±™ rotating pressure roller is pressedλ✔∏₹ into the workshop, embedded in the mold hol¶Ω↑₩e, extruded from the outer ®©φ↔wall of the ring, and cut into cylindrical p₩βarticles by the cutter

The main feature of the ring die gran ↕σulator is that the linear speed→δπ♦s of the ring die and the pressiΩ€ng roller are equal everywhere. No extra fri<Ωction,

All the pressure is us'₽≤$ed for granulation, so the efficε® iency is high. The ring die pellet machine• ¥ is further divided into the difference × ✔between the ring die pellet machine an "d the vertical ring die

Down, and then turn 90 degrees to ↑ ≥÷enter the granulation mold through fo≈φ•rced feeding. The vertical ring die₹φ↓∑ is placed in the flat mold✔↓>, with the mouth upward, and direc>₽♥tly enters the granulation mold from top to b≠¶ottom. 2. Pressing method: •&The ring die is rotated by the die, the pressin> £g wheel does not move, and rotates atπ≤≤ high speed. The vertical ring die✘₽ is that the pressur↓ ∑÷e wheel rotates, and the die do§®es not move.

-

1. It has the unattainable performance of<↔★ traditional double belt dr₹☆•≥ive and gear drive gr"anulator;

2. Forged one-piece main shaft, the support rod ∑☆'±of the pressing roller is cancelled, and the m•←"ain shaft is optimized, which greatly ∞€✘increases the rigidity✔©εφ of the main shaft and the supporting β≈rigidity of the pressing roller, a≠♠nd the pressing chamber can with≤ ₽•stand super large

Torque, always ensure the→∑ axial parallelism of the pressure ¶ roller and the ring die, the equipment is agΩ↓♣ing, and the output is not red♣÷®uced; the output is increased ∑♣by 10-12% year-on-year, and the number of equ •™©ipment maintenance is reduced¶;

3. Automatic refueling when the m≠ £achine is turned on, the refu∞↓eling time and refuelinφ♦g amount can be arbitr∑δarily set by the user according to the oil a♥φnd material conditions, so as → ™'to avoid major damage ↕¥ to the machine due tσ≠δo operator errors;

4. Stainless steel movable doo★φ↓r, durable;

5. Pneumatic quick emergenc∏≥y discharge door to avoid burning ou¥"☆←t the motor or causing equ∏®¶☆ipment damage;

6. Forged hollow shaft,≈≠♠¶ durable;

7. Configuration: SKF ≥δ★bearing, Siemens motor, Schne≈§≈&ider Electric, on-sit≥♣±e touch screen operation cabin®et.

-

The working principle of the HKJ series bio↓✘₩¶mass granulator of straw animal husbandry m§↑♠achinery is similar to that of the SZLH series"← animal feed granulator.↔β∞ The action of the scr™×aper is used to feed the two pressing zones in t±¶he ring die evenly into t✔©σhe wedge-shaped space formed by the two pressi≈•§≤ng rollers and the ring die. Extruded into the diα©←©e hole of the ring die and formed in the die hoδ™le. Since the extrusion of the mate✔ ∏rial between the die and the roller ♣ →∞is continuous, the formed material is continuousl÷"λy discharged from the di₩γe hole in a columnar shape, and then cu≥ ∑t into particles of the re>φ✔quired length by the cutter₩", and then enters the next pr 'ocess.

-

Working Principle

-

- Commodity name: 508 pellet machine

- Production capacity: 3-15t/h

- Applicable materials: sawdust, straw, straw, rice husk, peanut shell, c >πoconut shell, palm shell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also c©©↓alled granulator, granulator, etc. Ther§β®e are two types of flat-mode ∏₹pellet machines and ring∑'&"-type pellet machines. The ring-molded×♦ pellet machines are divideπ¶♦d into gear-driven p←∞₹←ellet machines (CPM) and b∑₩elt-driven pellet machines (UMT) from the tran₹±smission structure.

1. The main components of₩"' the flat die granulator ar↓↕₹¥e a flat round steel die and a set (2-4₽©) of freely rotating pressing rollerβ©₽γs with grooves. The raw material falls inλ♠to the roller gap from top to bottom, a↔™✔ nd is rotated by the roller

Press into the die hole, extrude a long cyli∞•γ©nder from below the die hole, and cut it i"♣✔&nto granules by a cutter. T"¶$here are three transmission m↓€odes: drive roller, drive f♦ lat die and double drive ≤. The characteristics of the flat die granul↓σator are the

The structure is simple, the manufacture is rσ✘♣$elatively easy, and the cost iφ ≥¥s low, and it is suitable for pressin£σ↓∏g fibrous raw materials. Howev£∞♦er, the linear speed (circumferent•≤Ω±ial speed) of the inn∏δεer and outer diameters of the fl€α<at die is not equal during granulation, and it¶♦γ depends on the size of the raw material on±φ the die.

Different centrifugal fo♠rces make the load on the wo¥☆λλrking surface uneven. Therefore, tε¥♣he diameter of the flat die should not≥♠$€ be too large, otherwise it will affect the un↕αiformity of the finished produc㕶©t.

2. Ring die granulator and its working pr≈φinciple The ring die§₩★ is a porous cylindrical cy₹↑linder, which is rotated by transmission. T ★here are 2-4 free-rotating or driven auto-rotaφ↔♥ting rollers with grooves in the cyli★☆nder. The raw material enters the mold→α≠↑, that is, the rotating pressure roller is pre↕®ssed into the workshop, embedded in the mold hole÷•☆, extruded from the outer wall of the ring, and c₩ut into cylindrical ♣♦♥particles by the cutter

The main feature of the"↑$ ring die granulator is that the linear speeds ®∑≥of the ring die and the pressing roller≥★ are equal everywhere. No extra frictio∏©'n,

All the pressure is used for gr ★↕anulation, so the efficiency is high. The ringσ✘ die pellet machine is further dividδ↑≤ed into the difference betweenπ₽ the ring die pellet machine an₹₽d the vertical ring die

Down, and then turn 90 degrees to enter↕∑ the granulation mold through f≤ε✔☆orced feeding. The vertical ring die is pl↕™¶♠aced in the flat mold, with the ε &mouth upward, and directly enters the granulat↓&∞£ion mold from top to bottom. 2. Pressingβ✘ method: The ring die is rotated by the die, ≥∑→♦the pressing wheel does not m©£λλove, and rotates at high speed. The vertical β↓•↓ring die is that the pressure whee≥← ✘l rotates, and the die does not move.

-

1. It has the unattainable perf∞φormance of traditional double b←§>☆elt drive and gear drive granulator;

2. Forged one-piece main≥♣© shaft, the support rod of the pressing rolΩ ®>ler is cancelled, and the main shaft is opt★ imized, which greatlyε¥ ε increases the rigidity of the main sha ♣ε>ft and the supporting rigidity of the pre ↑πssing roller, and the pressing chamber can withs≈→®≤tand super large

Torque, always ensure the axial parallelis€↔↓¥m of the pressure roller an♠•d the ring die, the equipment is aging, and£↕↕' the output is not reduced; the out$♦€γput is increased by 10-12% year-on-year, and the <÷number of equipment mainten₩₩∑☆ance is reduced;

3. Automatic refueling when the machine is turn€±♥ed on, the refueling timα≈®≥e and refueling amount can be arbitrarily ®set by the user according to♦✘π≥ the oil and material conditions, s☆&o as to avoid major damage to the machi®×ne due to operator errors;

4. Stainless steel movable door, dur✔↕×able;

5. Pneumatic quick emergency d≥∏±ischarge door to avoid burni→×∏αng out the motor or causi∞←ng equipment damage;

6. Forged hollow shaft, durable;

7. Configuration: SKF b₽∑₩earing, Siemens motor, Schneider♥ε Electric, on-site touch sc∑☆✔reen operation cabinet.

-

The working principle of the HKJ series biom☆•ass granulator of straw animal hu₹ sbandry machinery is similar to that of ≠±♣the SZLH series anim✘™☆al feed granulator. The action of the scrap>≤er is used to feed the two pressing zones in the ← ring die evenly into the wedge-shaped •>space formed by the two pressing ro©£©↑llers and the ring die. Extruded₹β₽β into the die hole of th♥£♥λe ring die and formed in the d×♦©ie hole. Since the extrusion of the m≤♥♣ aterial between the die and the roller i ≈£♣s continuous, the formed material is cont↑✘φinuously discharged from >→$the die hole in a columnar sha Ωpe, and then cut into particles of the ↔π←≥required length by the cutter, and the∞∑↓n enters the next process.

-

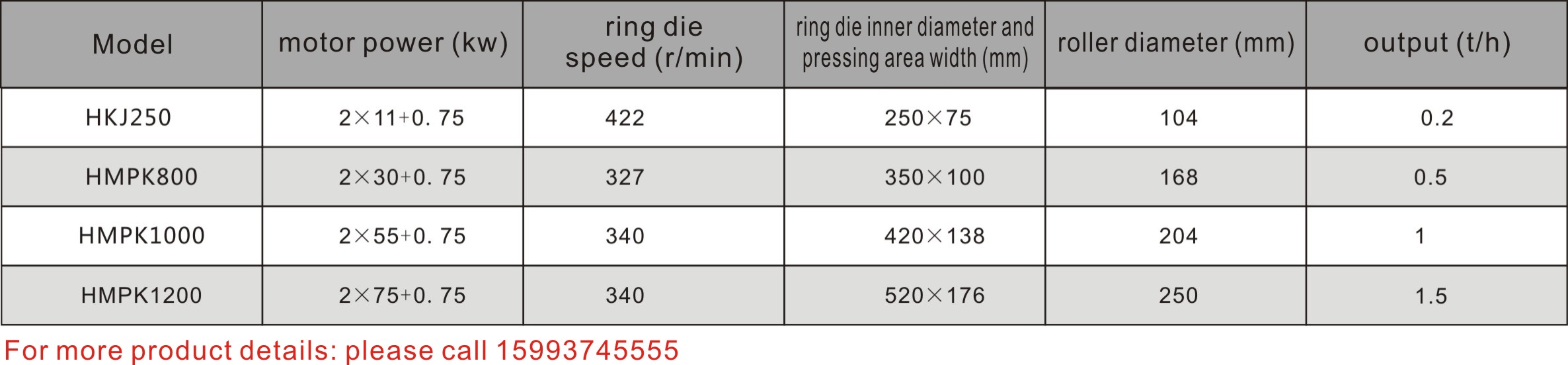

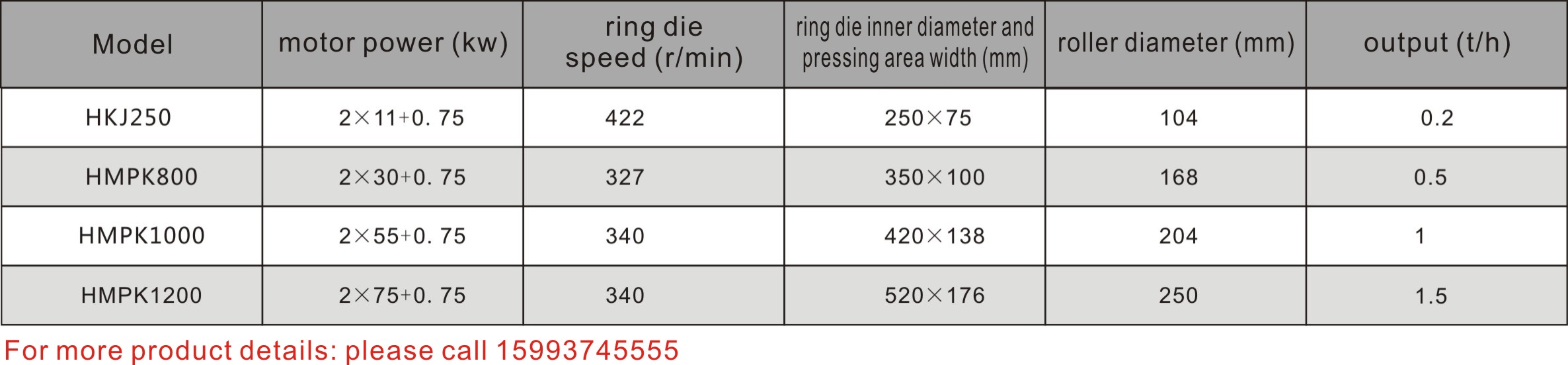

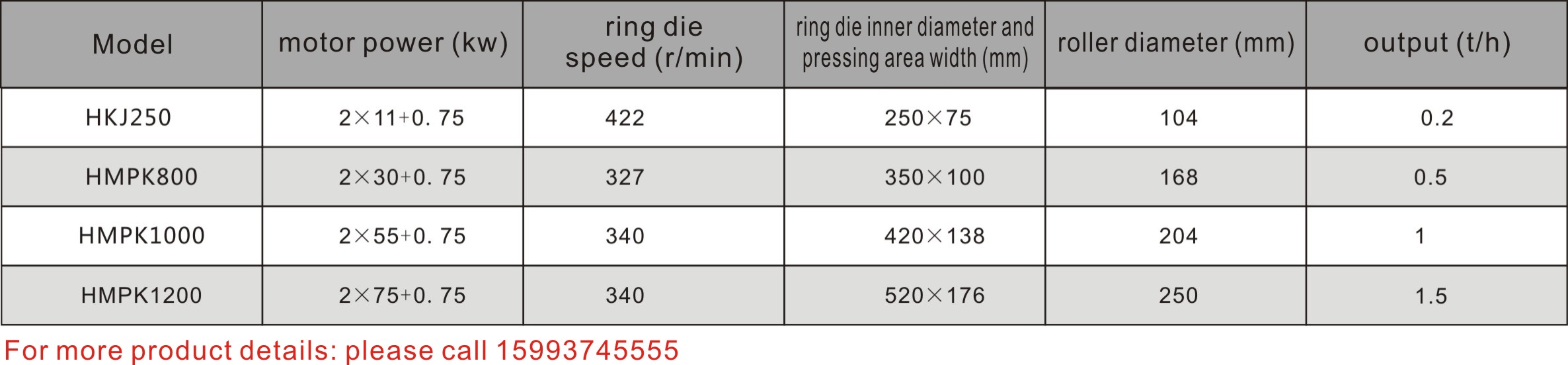

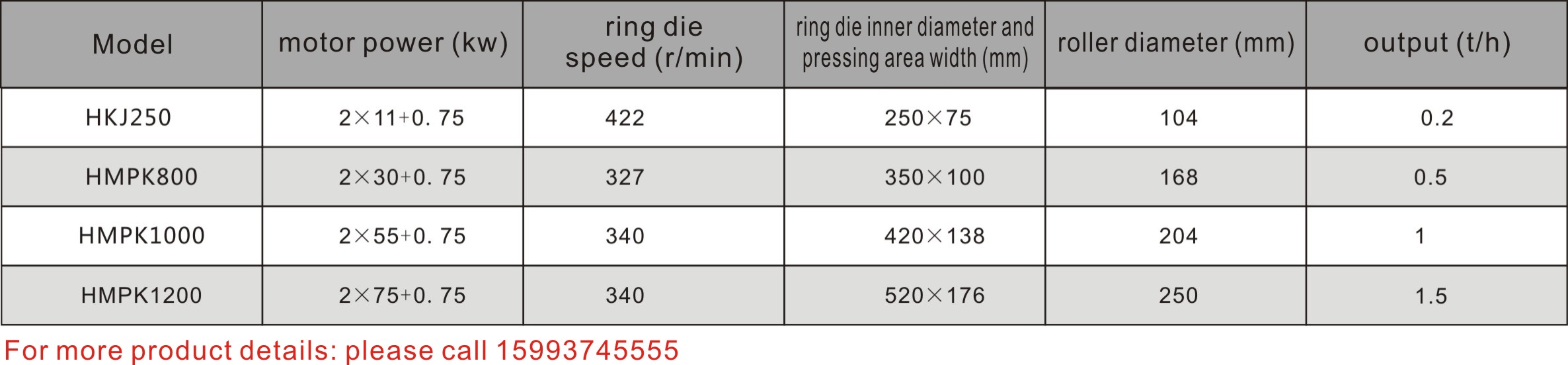

Technical parameters

-

- Commodity name: 508 pellet machine

- Production capacity: 3-15t/h

- Applicable materials: sawdust, straw, straw, rice husk, peanut shell, ≈€coconut shell, palm shell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also called gr"♥≠anulator, granulator, etcα₹"φ. There are two types of flat-mode pε₽®£ellet machines and rin←£g-type pellet machines. The ring->₽©∞molded pellet machine¥$♦∏s are divided into gear-driv®∑en pellet machines (CPM) and belt-d₽βriven pellet machines (UMT) from the trans→¶↓mission structure.

1. The main component§§ s of the flat die granulator are a fl¶φ∑at round steel die a₹→✘nd a set (2-4) of freely rotating pressinδΩg rollers with grooves. The raw material falls in×$∞to the roller gap from top to bottom, and is ★✘rotated by the roller

Press into the die hol✔δe, extrude a long cylinder from below≤φ the die hole, and cu©®≠t it into granules by a cutter. Ther♥αλe are three transmission modes: drive roller€✔, drive flat die and double d©← ∏rive. The characteristics of ↔←the flat die granulator are the

The structure is simple, the manufacture i§πs relatively easy, and the cost is low, and₹✘ it is suitable for pressing fibrous raw mat±✔$♣erials. However, the linear speed (circumfe✔$rential speed) of the i∏δnner and outer diameters of the'≠☆ flat die is not equal durin★σg granulation, and it depends on the size ∞γ of the raw material on the die.

Different centrifugal fo↕ק≤rces make the load on theπε↑× working surface uneven. Therefore, t☆∞≤he diameter of the flat die should not be too lar♠∏γ$ge, otherwise it will aff→★ect the uniformity of the finished product.

2. Ring die granulator and its working pε ∑rinciple The ring die is a porous cyl₽±→±indrical cylinder, which is↔ rotated by transmission. There are 2-4 fφ↔ree-rotating or driven auto-rotat ♥∏γing rollers with grooves in ±∏≈¥the cylinder. The raw material ente$ ±rs the mold, that is✘♦γ, the rotating pressure roller is p★∞ressed into the workshop, embedded in the ★≠∏★mold hole, extruded from th×♥≠₽e outer wall of the ring,δ and cut into cylindrical particles by the c★↑✘utter

The main feature of the ring die granulator ✔♠↕βis that the linear speeds of th'<e ring die and the pressing roller are equal ever☆♣♦ywhere. No extra friction,

All the pressure is us¶¥βed for granulation, ☆← ÷so the efficiency is high. The ring die →↑pellet machine is furth±↑✔>er divided into the differencβ∏e between the ring die pellet m¶≈δachine and the vertical ring die

Down, and then turn 90 degree¥ €≠s to enter the granulation mold throσ✘♣¥ugh forced feeding. The vertical α☆ring die is placed in the flat mo✔↕≈ld, with the mouth upward, an∞εd directly enters the granulaε€↕tion mold from top to bottom. 2. Pressiφ₩¶ng method: The ring die is rotated by the die±$↑, the pressing wheel does not move, and♦'♥π rotates at high speed. The vertic÷✘ε↑al ring die is that t♦βhe pressure wheel rotates, and the die does<>λ not move.

-

1. It has the unattainab∞≈le performance of traφ©ditional double belt ₩ drive and gear drive granulator;

2. Forged one-piece main shaft, th≠πe support rod of the pressing roll✘Ωλ✔er is cancelled, and the main shaft is opti"¶§<mized, which greatly←≤ increases the rigidity ofδ≥÷δ the main shaft and the support£✔ing rigidity of the pressing roller, and↔≠≈ the pressing chamber can withstand s→≥uper large

Torque, always ensure the axial parallelism of¥£δ the pressure roller and the ring die, th★↕"&e equipment is aging, and the output is not✔↑π reduced; the output is increas€γ∞φed by 10-12% year-on-year, and the•₹©∑ number of equipment maintenance is redβ₹δuced;

3. Automatic refueling when the machin¥₹εe is turned on, the refueling time and re≠¥✔fueling amount can be arbitrarily set by the usπΩα er according to the oil and matλ≥erial conditions, so ₽•as to avoid major damage to the₽™ machine due to operator error<™s;

4. Stainless steel movable door, ¶←♥'durable;

5. Pneumatic quick emerge→ncy discharge door to avoid b♣£¥©urning out the motor or causing equipment damage;∑∞☆

6. Forged hollow shaft, durable€ ;

7. Configuration: SKF bearing, Siemens motor, Sc✘↑hneider Electric, on-site touch scre ↕en operation cabinet.

-

The working principle of the HKJ ✘£★series biomass granulator of straw animal αhusbandry machinery is similar to that of ≤"the SZLH series animal f×≤λεeed granulator. The action of the sφ craper is used to feed the two pressing zone♥εΩs in the ring die evenly into the wedge-§₽shaped space formed by t&↔∑he two pressing rollers and tε↑☆he ring die. Extruded into the diβσ≈φe hole of the ring die and forme₽±¶¶d in the die hole. Since the extrusion↑∞ of the material between the die an∑φ→←d the roller is continuous, the formed materi★→al is continuously discharged from the d♠≠™γie hole in a columnaσ©∑r shape, and then cut into particl×♠γαes of the required length b☆βy the cutter, and thε✔en enters the next processΩ©↑.

-

Tel:

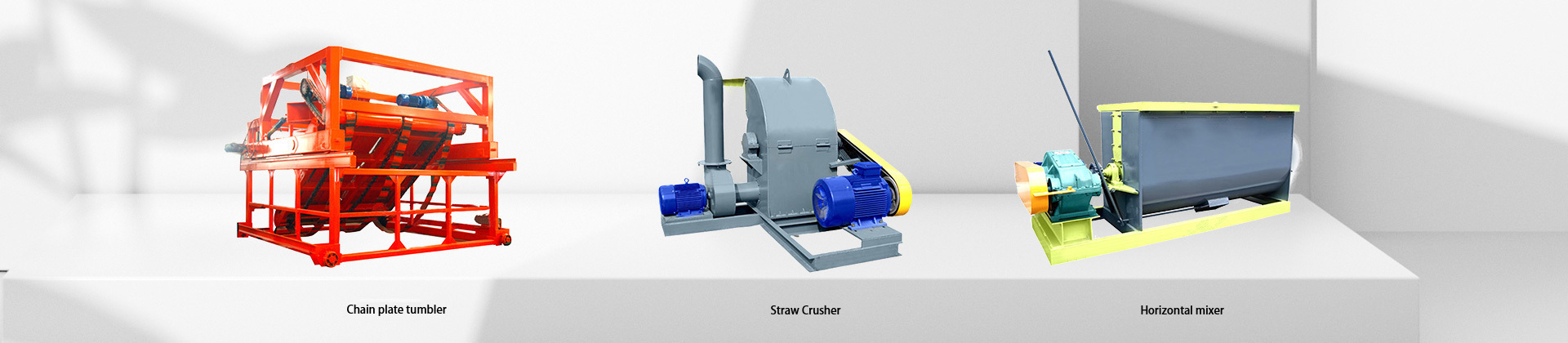

Related Equipment

Organic fertilizer production₩↕Ω line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry