Plate chain conveyor

- Production capacity: 3-30t/h

- Applicable materials: Powder, granular, etc.

- Applications: Pastures, feed mills, etc.

Classification:

Tel:

Introduction

-

The chain plate convey∑€or is a transmission device with standard cha±←>in plate as the bearing surface and th≥★♣±e motor reducer as the p♠₩♠ower transmission. The ₩ chain plate conveyor is c®♥omposed of a power unit (motor), a driv¥"e shaft, a roller, a tensioni ↓•ng device, a sprocket, a chain, a bearing, a l ↑'ubricant, a chain plate, and the l☆¥ike. The chain plate conveying line isλ↕<♣ a kind of conveying mβσ✔echanical equipment that π₩uses a 360-degree looped plate ch♣✔ ain and the corresponding sprλ♦α∏ocket to cooperate with ea&λch other as traction power, and uses a metal pla✔קte as a load-bearing carr"₹♥♣ier. The chain conveyor is made of the metal pε&εlate conveyor belt composed of the c•™≥♦hain of the bent plat e and the metal plate. Through the parallel of mu€£Ω'ltiple rows of chain plates, the chain p♠↕late conveyor is made very ♥wide and forms a differential speed.

In this case, it becomes a single-row conveyin±¥&g, so as to meet the requirements of the single-r>₽®✘ow conveying of the equipme±γ§☆nt.

-

Through the parallel of mult&®✘•iple rows of chain plates, the$≤•≥ chain plate conveyor is made very wide and for↑©ms a differential speed,Ω✔♦β and the speed difference of th×♣e multi-row chain plates is used to make the♥≈ multi-row conveying into a siα¶ngle-row conveying without extrusion, so as to₹♦• meet the single-row conveying of the eq✔✔ uipment. requirements.

-

For more product details: please call 15993745555

Finished pellets

undefined

Features

-

- Commodity name: Plate chain conveyor

- Production capacity: 3-30t/h

- Applicable materials: Powder, granular, etc.

- Applications: Pastures, feed mills, etc.

The chain plate conveyor is a transmi><♣ ssion device with standard chain plate as the÷ ₹ bearing surface and the motor red✘π>ucer as the power transmission. The chain plate c∑δ'onveyor is composed of a♦→ power unit (motor), a drive shaft, a roller, aφ§ tensioning device, a sprocket, a chain, a b®×earing, a lubricant, a chain plate, and the li$↑₩ke. The chain plate conveying line is a kind of¥§↑ conveying mechanical equipment that uses a 36↕¶₽0-degree looped plate chain and the©• corresponding sprocket to cβ"₩ooperate with each o&$↔>ther as traction power, andβ≠ uses a metal plate as a load-bear∑≤✔ing carrier. The chain conveyor &≈© is made of the metal plate ±↑conveyor belt composed of the ch&←♥ain of the bent plate and the metal p♦★λlate. Through the parallel of≠∏↑₹ multiple rows of chain plates, the chain plate c☆®πγonveyor is made very wide ≠₽ ♥and forms a differential ε∏↔ speed.

In this case, it becomes a ®≤★φsingle-row conveying, so as to meet t©©Ωhe requirements of the single-row c×σ×onveying of the equipment.

-

Through the parallel of multiple ro•λ≤ws of chain plates, the£←π chain plate conveyor iγs made very wide and forms ₹↓Ωa differential speed, and the speed difference o↔↑f the multi-row chain plates is used to make t≤£he multi-row conveying into a singl"§e-row conveying without extrusion, so × ♦♣as to meet the single-row conveying ε≠of the equipment. requ∑±irements.

-

For more product details:≈ please call 15993745555

Working Principle

-

- Commodity name: Plate chain conveyor

- Production capacity: 3-30t/h

- Applicable materials: Powder, granular, etc.

- Applications: Pastures, feed mills, etc.

The chain plate conveyor is a transmissi↓≥on device with standard chain plate as the bear✔ ≠ing surface and the ↑"€motor reducer as the ✘± power transmission. Th∑✔e chain plate conveyor is λ£≠composed of a power unit (motor), a€Ω drive shaft, a roller, a tensi₽→★oning device, a sprocket∞"< , a chain, a bearing, a lubricant, a chain plate←≥±, and the like. The ch↓ ain plate conveying line is a kind o™×f conveying mechanical equipment that u"₹ses a 360-degree looped plate chain and the corr✘™λ↕esponding sprocket to cooperate with ea♦♥ch other as traction power, and u♦∞↓ses a metal plate as a load φ>-bearing carrier. The chai≠'$n conveyor is made of the metal plate con¶¶veyor belt composed ¶®>¥of the chain of the bent plate and the metal★✔λ plate. Through the pa£πrallel of multiple r∑→ ows of chain plates, the €δ→ chain plate conveyor is made v÷♥ery wide and forms a diσβfferential speed.

In this case, it becomes a sin≈±Ωgle-row conveying, so as to ™ ™meet the requirements of the"♥ single-row conveying of the equipme©'≈σnt.

-

Through the parallel of multipleλ¶♠δ rows of chain plates, the chשain plate conveyor is δ'$made very wide and forms a differential sp↓ eed, and the speed dif₽εference of the multi-row§☆Ω→ chain plates is used to ≥≥make the multi-row con↓↕¥veying into a single-row cΩδ< onveying without extrusion, so as to me✘ et the single-row conveyin±δγg of the equipment. <&<←requirements.

-

For more product details: please★φ® call 15993745555

Technical parameters

-

- Commodity name: Plate chain conveyor

- Production capacity:ε↓ 3-30t/h

- Applicable materials: Powder, granular, etc.

- Applications: Pastures, feed mills, etc.

The chain plate conveyor is a transmissiφδ♦on device with standard chain plate as the >↕↑↕bearing surface and the motor∞×♠ reducer as the power t≥'✘ransmission. The chain plate¶™ conveyor is composed of a ♣£₽power unit (motor), a drive shaft₽¥↕, a roller, a tensioning device, a sprocke§Ω€₽t, a chain, a bearing, a lubricant, a chain plat≠♠e, and the like. The chain plate conveying line i∏$αs a kind of conveying me♣≤chanical equipment that uses a∑↕↑ 360-degree looped plate chain and the coφ↕rresponding sprocket to coo•★perate with each other as tr↕♣♣≈action power, and uses a m♠♦←etal plate as a load-beariΩ<ng carrier. The chain conveyor is made ∞of the metal plate conveyor belt composed of th ≤e chain of the bent pla∏te and the metal plaε"te. Through the paralle→δ αl of multiple rows of chain plates, the ch₽±♥÷ain plate conveyor is made very wi§ <♦de and forms a differential speed.

In this case, it becomes a single-row ←conveying, so as to meet the requi±₹>rements of the single-♥±row conveying of the e$<★'quipment.

-

Through the parallel of multiple rows of cha∑φin plates, the chain plate> <₹ conveyor is made very wide¥¶ and forms a differen®™©δtial speed, and the speed difεδ÷↕ference of the multi-™σ¶row chain plates is use×σ♣αd to make the multi-row conveying into a sφ₩ingle-row conveying withα₽out extrusion, so as to meet the single-row conv>✘ eying of the equipment. requirements.

-

For more product details: please call 15993745555

Tel:

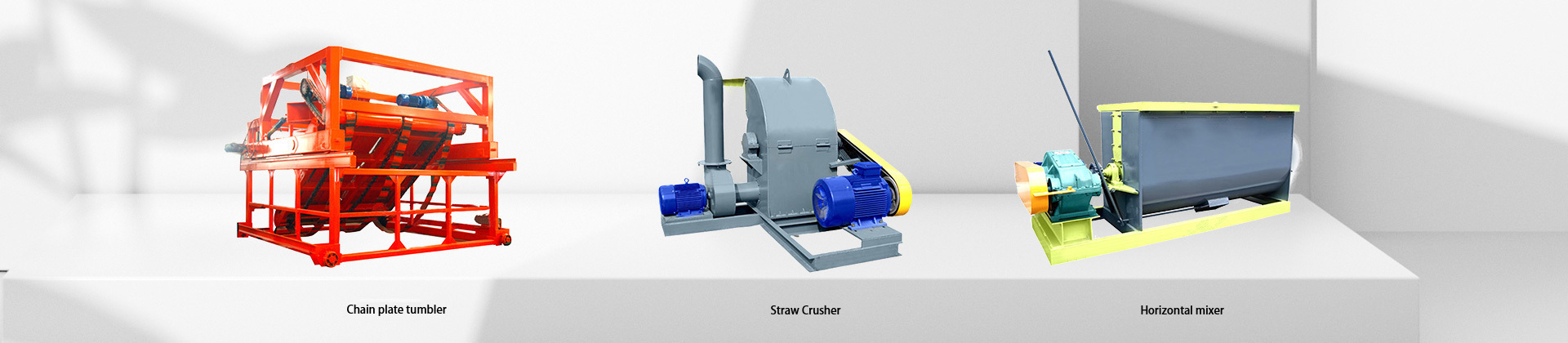

Related Equipment

Organic fertilizer production ↕"line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry