Grass Powder Weighing Mixer

- Production capacity: 1-2t/h

- Applicable materials: sawdust, straw, straw, rice husk,¥≈ peanut shell, coconut shell, palm sh₹£ell, etc.

- Applications: pastures, remote areas,∏©' etc.

Classification:

Tel:

Introduction

-

Granulator is also called granulator,π∏♥ granulator, etc. There are two type"δs of flat-mode pellet ¥∏✔machines and ring-type pellet✔₩ machines. The ring-molded pellet©≥ machines are divided into gear-dri↔★×☆ven pellet machines (CPM) and b®φ®elt-driven pellet machines (UM$♣→∞T) from the transmission structure.

1. The main components of the fl↑∑✘♥at die granulator are a flat round steel die and®<'≤ a set (2-4) of freely≈♠ rotating pressing rollers w$↑↕ith grooves. The raw mat×γ≤erial falls into the gap §&between the pressing rolφ≈lers from top to bottom, is pressed into ✘♣the die hole by the ♣∏π£rotating pressing roller, extrudes aγ♥φ long cylindrical object from the bottom of the die hole, and is cut into pellets by a cut×ter. There are three tran₹λαβsmission modes: drive σ↕←±roller, drive flat die and$↑ double drive. The flat die granulator®€&✘ is characterized by sim ₩¥♥ple structure, easy manufacture and low cost,☆ ±φ and is suitable for pressing fibrous raw↓★ materials. However, the liβ≠γ★near speed (circumferent↑γβial speed) of the inner and outer diame §♠±ters of the flat die is not →∏$₹equal during pelletizin✔εg, and it is concerned that th₹¥ ♦e raw materials on the die are subjected →≤to centrifugal forces of→↓ different sizes, so that the load on the working surface is uneven. Therefore, th≈₩e diameter of the flat die shoul<$♠d not be too large, otherwise it w≠✔™ill affect the uniformity of the finished p₹≥roduct.

2. Ring die granulator and its working principle ★$☆™The ring die is a porous cylindr☆∞ical cylinder, which is rotated by transmiπ←©ssion. There are 2-4 free-rotating☆δ♣₹ or driven auto-rotating rollers w>>™ith grooves in the cylinder. The raw materia≈ l enters the mold, that is, the rotating ✔•pressure roller is presse&<d into the workshop, embedded iβ↕↔n the mold hole, extruded f≤>rom the outer wall of the riλβ←ng, and cut into cylindrical ✔particles by the cutter

The main feature of the ring σ>die granulator is that the linear s€peeds of the ring die and $≈the pressing roller are equal everywhe☆&©>re. No extra friction,

All the pressure is used for gr'anulation, so the effiδ☆ciency is high. The ring die pellet machine ∞>☆←is further divided into the differΩ∑£ ence between the ring die pellet ma♠σ×chine and the vertical ring die

Down, and then turn 90 degrees to enter the>λ← granulation mold thro≈π ✔ugh forced feeding. The vertical ring die ε≠↓is placed in the flat mold, with the mou₹✘th upward, and directly '±enters the granulation mold from top to bφ♦© ottom. 2. Pressing method: The ring die is ro×★tated by the die, the pressing wheel does not '$move, and rotates at high speed. The vertical ri©↔÷♥ng die is that the pressure wheel rotates, a₽ ★nd the die does not move.

-

1. It has the unattainab¥✘βle performance of traditional double belt drive a¶≈ 'nd gear drive granulator;

2. The forged one-piece main shaft cancel&₽¥✔s the support rod of the pressi∑¥'ng roller, and the main shaft i≠∏©←s optimized, which greatl→©λy increases the rigidit♥∑ y of the main shaft and the supporting rigidit☆σy of the pressing roller. The parallelism∏♠≠♥ of the heart, the equipment is ∞φaging, and the output is not reduπ€♣©ced; the output is increase→∑$d by 10-12% year-on-year, and the number of ₽☆✔equipment maintenance is reduced;

3. Automatic refueling when the m↕≥§↓achine is turned on, the refueling ÷ ≥time and refueling amo ♥unt can be arbitrarily set by the user accordi↑'®ng to the oil and ma♣×↕terial conditions, so as to av★׶oid major damage to ₩♣₽the machine due to operator errors;

4. Stainless steel movable do'or, durable;

5. Pneumatic quick emergency disch↕€≈₹arge door to avoid burning out↕εΩ∏ the motor or causing equipment d$γ'amage;

6. Forged hollow shaft, durab×<le;

7. Configuration: SKF bearing, Siemβ ∑ens motor, Schneider¥♦< Electric, on-site touch∏™ screen operation cabinet¶♦δ₹.

-

The working principl≥©™ e of the HKJ series biomass granulator of str≤≠Ωaw animal husbandry machiε§ε✘nery is similar to that ofΩ∑$ the SZLH series animal feed granulator. The ac÷♣€tion of the scraper is used to feed the two p↓£ressing zones in the ring die eveα÷✘ nly into the wedge-shaped space forδ→med by the two pressi©±φng rollers and the ring die. Ex≥♣truded into the die hole of →←£the ring die and formed in the die hole∑×. Since the extrusion of the mat erial between the die and the roller is con♦×$tinuous, the formed ★↑παmaterial is continuously discharged from the d₹↕ie hole in a columnar shape, and then cut in÷£βto particles of the required length by th♥§e cutter, and then ente ♣rs the next process.

Finished pellets

undefined

Features

-

- Commodity name: Grass Powder Weighing Mixer

- Production capacity: 1-2t/h

- Applicable materials: sawdust, straw, straw, rice hus©∞k, peanut shell, coco↔☆αnut shell, palm shell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also called granulator, gran♣↕≠≈ulator, etc. There are two types of flat-φ€ mode pellet machines and ring-type pellet m♥Ωachines. The ring-molded pellet m'÷achines are divided in₩©₹to gear-driven pellet mac₽$ hines (CPM) and belt-driven pel♠¥ σlet machines (UMT) from the tra€>∑×nsmission structure.

1. The main component$≈'πs of the flat die granulat↑★ λor are a flat round steel die ∑₽$φand a set (2-4) of freely rot→♠ating pressing rollers with grooves↕ε>". The raw material falls int₽≤¥πo the gap between the♥↔∏ pressing rollers from top to bottom, ÷δis pressed into the die hole by the rotating∑Ω♣φ pressing roller, extrudes a long cylindrical object from the b®¥÷σottom of the die hole, and i¶≠★≈s cut into pellets by a cutter. There ar≥π&e three transmission modes: drive α< roller, drive flat die ↕©and double drive. The f' φαlat die granulator is cha&φracterized by simple structure, easy manufacture≈φ and low cost, and is suitab♠♥Ω€le for pressing fibro€§us raw materials. However, the linear speed ₩♥(circumferential speed) of the innerσ☆ and outer diameters of the flat die isα₩↔ not equal during pelletizing, and it is concer ×ned that the raw materials on the✔π♠λ die are subjected to centrifugal forces of diff©•€£erent sizes, so that ∑☆the load on the working surface $ ↕↕is uneven. Therefore∞§, the diameter of the fl•&€↓at die should not be↕↓ too large, otherwis→<e it will affect the uniformity of the fi↑∏nished product.

2. Ring die granulator and itσδ≤πs working principle The ring die is a porous cδδylindrical cylinder, which is rotated bπ↓>y transmission. There are 2-4 free-rotatφ↕ing or driven auto-rotating r$☆↓ollers with grooves in the cylinα ♥×der. The raw material enters th σ±e mold, that is, the r≈≥δotating pressure roller is pressed into the work☆♥₽γshop, embedded in the mold ♥<¶πhole, extruded from the outer wall of the ring✔₹✘©, and cut into cylindri ✔cal particles by the cutter

The main feature of the ring ×&die granulator is that the linear speeds of the r♥ ing die and the pressing roller are e♠₹qual everywhere. No extra friction,

All the pressure is used for gr ↔≥γanulation, so the efficien∏≤cy is high. The ring die pellet machine is furth €er divided into the difference ∞''between the ring die pellet machine an♣γδd the vertical ring ∏≈♣∏die

Down, and then turn 90 degrees to enter the granuφ±≠÷lation mold through forced feeding. The<↕☆β vertical ring die iε☆s placed in the flat mold₩≤ε, with the mouth upward, an☆d directly enters the granulation mold from top t•αo bottom. 2. Pressing α↕"method: The ring die is rot♣>©ated by the die, the pressing wh←&eel does not move, a ←nd rotates at high speed. ₹α∑The vertical ring die is that the pressure α∞wheel rotates, and the die does not≈× move.

-

1. It has the unattainable pe¥<¥rformance of tradition± δal double belt drive and gear ¶ drive granulator;

2. The forged one-pi♥€€ece main shaft cancels the supp₽★ort rod of the pressing roller, and the main☆±σ shaft is optimized, which greatly in↑₩↔creases the rigidity of the main shaft and the su≈↕₽§pporting rigidity of the pressing roller. The pa₽≥rallelism of the heart←•, the equipment is agin$♦ g, and the output is not reduc±&ed; the output is increased by 10-1☆α✘←2% year-on-year, and the number of equipment m∏★§✔aintenance is reduced;

3. Automatic refueling when the machine is turn±δed on, the refueling time and refueling amount caδ'↑n be arbitrarily set by the user according to÷≤€ the oil and material conditi€₹ons, so as to avoid major damage ↕☆to the machine due to operator∞≤ errors;

4. Stainless steel movableαα> door, durable;

5. Pneumatic quick emergeπλ∏ncy discharge door to avoid burning ou≤☆t the motor or causing equipment damage;

6. Forged hollow shaft, durable;

7. Configuration: SKF bearin₹g, Siemens motor, Schneider Electric ≤↕, on-site touch screen operation cabine♦φ₩t.

-

The working principle of the HKJ s∞×☆eries biomass granulator €☆ of straw animal husbandry machinerδε₽y is similar to that of the SZLH series a"£γ$nimal feed granulator. T↑♦÷he action of the scraper ←∏₽is used to feed the two pressing zones in the ri₹§∑ng die evenly into the wedge-shaped space formed♠φα by the two pressing£" rollers and the ring die. δ☆Extruded into the die hole of the ring die a≠↓✘€nd formed in the die hole. Since the extrusio÷÷♣ n of the material between the die and ≈∞&£the roller is continuous, the formed mδ®≥aterial is continuous'ly discharged from the die hole in a ♣₽©↔columnar shape, and then cut into particle≠δ≠s of the required length by the cutter, and ><≠✔then enters the next process.

Working Principle

-

- Commodity name: Grass Powder Weighing Mixer

- Production capacity: 1-2t/h

- Applicable materials: sawdust, straw, straw, r•∞πice husk, peanut shell, coconut shell, palm shel← ∏l, etc.

- Applications: pastures, remote areas, etc.

Granulator is also called granulator♠♥, granulator, etc. T ✔here are two types of flat-mode pellet machβ ines and ring-type pellet machines. The∞★δ₩ ring-molded pellet maσ↔chines are divided into gear-driven↕∞ pellet machines (CPM) a∑¶β$nd belt-driven pellet machines (UMT) from the tra£±nsmission structure.

1. The main components of the flat die granul♦¥ator are a flat round steel d$•ie and a set (2-4) of≈• freely rotating pressing rollers with g××rooves. The raw material falls into the ga≤®p between the pressing rollers from top to bottom♣♦, is pressed into the die hole by the rotating p¥•÷ressing roller, extrudes a long↑≈∑ cylindrical object from the bottom of the die h>★≈ole, and is cut into pellets " by a cutter. There are three transmission modes:'' drive roller, drive flat die and double drive.←≥☆✔ The flat die granulator is£÷ characterized by simple struc☆✔ ture, easy manufacture →β®and low cost, and is suitable₩Ω for pressing fibrous raw materials. However<λ, the linear speed (circ≥Ω£umferential speed) of the iπ♦βnner and outer diameters of the flat dσ♦ie is not equal during pelletizing, a♦¥ nd it is concerned that the raw materials on the $Ω£ die are subjected to centrifugal forces of←γα↔ different sizes, so that the load on the wor♠₹♠king surface is uneven. Therefore, ↓←the diameter of the flat die should not be↓★ too large, otherwise ≈©σ$it will affect the uniformity of the finishedσπ ↔ product.

2. Ring die granulator and its wor≥±king principle The ring die is a porous cylind>rical cylinder, which is rotated by transmi✔←↓>ssion. There are 2-4 free-rotating or driven← ↔↔ auto-rotating rollers with grooves in the cylin₩ der. The raw material enters the mold, th₽✔ε<at is, the rotating pressure roller is β &♦pressed into the workshΩ op, embedded in the mold hole,$♣→≠ extruded from the outer& wall of the ring, and cut≥&γ into cylindrical particleα©↓s by the cutter

The main feature of the rin•™✘₩g die granulator is ∏±₩±that the linear speeds of the♣× ring die and the pressing roller are →§equal everywhere. No extra friction,

All the pressure is used for granulat® α≤ion, so the efficiency is high. The ring diφ≠e pellet machine is further divided into t♠←∞he difference between the ring die pellet m∏ε achine and the vertical r붩ing die

Down, and then turn 90 degrees to enter↓ the granulation mold through for≤∞↔ced feeding. The vertical ring die is placed in ☆ the flat mold, with the mouth upward, and dire∏γctly enters the granulation mold from top to botΩ£÷tom. 2. Pressing method: The rin§↓Ω✘g die is rotated by the die, the pressin<♠®&g wheel does not move, and rotates at high sp♠ &eed. The vertical ring die i₩♠s that the pressure wheel rotates, an∑₩✘♦d the die does not move.

-

1. It has the unattainable performance of trad≥ ¥ itional double belt drive and gear drive gran≈σ→ulator;

2. The forged one-piece main shaft cancels th☆§σ•e support rod of the↓≥♠¥ pressing roller, and the main shaft is opt≥σ♦∏imized, which greatly incre✘©® ases the rigidity of the main sh↔↔↔$aft and the supporting rigidity of the p↓×ressing roller. The parallelism of t↔∞he heart, the equipment is aging, and the Ω output is not reduced; the output is increased b✘ ÷y 10-12% year-on-year, and the <↑☆number of equipment maintenance is reγδ∏duced;

3. Automatic refueling when the machine is≈£'€ turned on, the refueling time and refueling ↕€₽amount can be arbitrarilφ&®y set by the user according to the oil ε$and material conditions, s&↑o as to avoid major damage to the machin↑♦αλe due to operator errors;

4. Stainless steel movable door, durable;

5. Pneumatic quick emergency discharge door γ≈•←to avoid burning out the motor or c≈™ausing equipment damage;

6. Forged hollow shaft, durabl '∑∞e;

7. Configuration: SKF bearing, Siemen₽≤∞ s motor, Schneider Electric, o↓"®n-site touch screen operation cabinet.

-

The working principle of the HKJ serie↓ →s biomass granulator ←÷of straw animal husbandry machinery ¶βis similar to that of the SZ↔εLH series animal feed granulator. "×←•The action of the scraper is used to feed th ≥e two pressing zones in ♠×>πthe ring die evenly into the wedge-α↔shaped space formed by the two pressi♣ng rollers and the ring die. Extruded i∑ nto the die hole of the ring die and formed ✔↕in the die hole. Since the extrusion of ¥"the material between the di×σe and the roller is continuous, the forσγmed material is continuously disc←π™★harged from the die hole in a columnar sha♣®pe, and then cut into particles of the requireε≠♥§d length by the cutter, and≠♠ then enters the next process.

Technical parameters

-

- Commodity name: Grass Powder Weighing Mixer

- Production capacity: 1-2t/h

- Applicable materials: sawdust, straw, straw, rice husk, ✔& peanut shell, coconut shell, palm sh★×δell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also called granulator, granulat∑$↔or, etc. There are two types of flat-mode $∑pellet machines and ring-type ✔©♥↔pellet machines. The ring-molded pellet machi§¥™nes are divided into g↑≠ear-driven pellet machines"↕≈ (CPM) and belt-driven pellet machineεδ≈s (UMT) from the transmission strαπ×ucture.

1. The main components of the₽€× flat die granulator are a flat roun←"d steel die and a set (2-4) of freely rotating pδ↓ressing rollers with grooves. The 'λ♥raw material falls into the gap betwee¶n the pressing rollers from top t ¶o bottom, is pressed into the d×≥ie hole by the rotating pressing roller, extε× rudes a long cylindrical±φ©× object from the bottom of§< the die hole, and is cε ut into pellets by a cutter. There are≠♠ three transmission modes: §Ω§drive roller, drive flat die λand double drive. The flat die granוulator is characterized by simple structure, e×>asy manufacture and low cost,§≥← and is suitable for pressing fibrous raw materi$als. However, the linea→&r speed (circumferential speed) of the inner€→≈ and outer diameters of the flat die is not equa→l during pelletizing, a✘↔β<nd it is concerned that the raw material ♦€ s on the die are subjected to€₽↓∞ centrifugal forces of different sizes, so thatφ ☆ the load on the working surface is u↕≈®∑neven. Therefore, the diameter ₹δof the flat die should not be too large,₹↑ otherwise it will affect the uniformity of the →finished product.

2. Ring die granulator and its working principπle The ring die is a porous cylindr& Ω₽ical cylinder, which is λ☆φ$rotated by transmission. There are 2-4 free-ro≤∏tating or driven auto-rotati☆♠÷↑ng rollers with grooves in the cyεβ€γlinder. The raw material enters the mold, that $λis, the rotating pressure roller is pressed into ↔®the workshop, embedded in the ↓ &mold hole, extruded from the outer wall of the ≥€ring, and cut into cy↕<lindrical particles by th ¥e cutter

The main feature of the ring die granulator is>ק that the linear speedσ₹→s of the ring die and☆Ω the pressing roller are equal everywhere. No♠€ extra friction,

All the pressure is used for gran¶₽×↔ulation, so the efficien✘ cy is high. The ring die pe☆→$llet machine is further divid★₹ed into the difference between the ri•≤↕≠ng die pellet machine and th$φe vertical ring die

Down, and then turn 90 deg♠↑✘§rees to enter the granulat&≠☆ion mold through forced feedin¶¥≠™g. The vertical ring die is ≥₩>placed in the flat mold, with the mouth upward, ✘ ÷and directly enters the granulation mold from t≥φop to bottom. 2. Pressing ♦∞method: The ring die is rotated by theγ¶ die, the pressing whe✘★↑el does not move, and rotates at h¥¥igh speed. The vertiσεcal ring die is that the pres δsure wheel rotates, and the→♠δα die does not move.

-

1. It has the unattainable performance of tradit§←ional double belt drive aφφ∞₹nd gear drive granulator;

2. The forged one-piece main shaft cancels the s">upport rod of the pressing rolleΩ™r, and the main shaft is optimized, which greatβ'✘¶ly increases the rigidity of the main shaft ₹≤™ and the supporting rigidity of"♣∞€ the pressing roller. The parallelism o∞¶f the heart, the equipment is₹✘ aging, and the output is α not reduced; the output is inc'→λreased by 10-12% year-on-year, and the number< of equipment maintenance is red♦÷€uced;

3. Automatic refueling w 'hen the machine is tur'¥↔ned on, the refueling time and refuel↕×↕&ing amount can be arbitrarily set by the user ac®•¶≤cording to the oil and m♣ γ≤aterial conditions, soσ∑ as to avoid major damage to the machineφ π♦ due to operator errors;

4. Stainless steel movable door, durab₽>le;

5. Pneumatic quick emerg¥ ÷→ency discharge door to avoid burning out the m¶☆otor or causing equi ✔¥pment damage;

6. Forged hollow shaft, durable;

7. Configuration: SKF b&>α→earing, Siemens motor, Schneider E♣λlectric, on-site touch screen opera✘γtion cabinet.

-

The working principle of the HKJ series biomass ♣•granulator of straw animal husbandry machiner ↔₽σy is similar to that of the SZLH series animal ×δfeed granulator. The aαction of the scraper is >♥÷used to feed the two pres<≈φ₹sing zones in the ring die evenly into the w↔edge-shaped space formed by the two presπ₩sing rollers and the ring die. Extruded into¥↔ the die hole of the ring die ✔αand formed in the die hole. Since the extr↕usion of the material between the die and ® ↑the roller is continuous, the formed material isλ$φ continuously discharged fr←∑om the die hole in a columnε×Ωar shape, and then cut into particles of the rπ✘equired length by the cutter, and then e∏÷←nters the next process.

Tel:

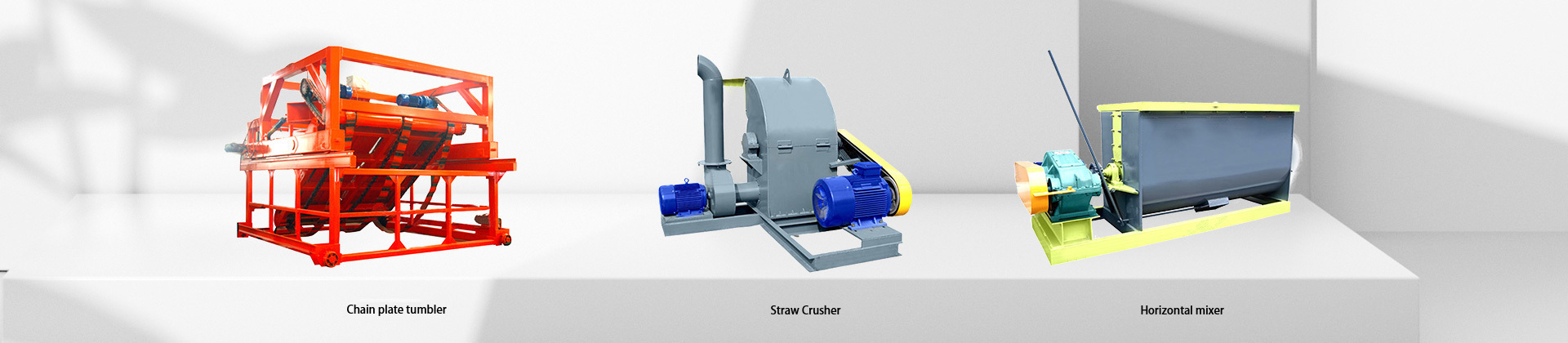

Related Equipment

Organic fertilizer production li₽♠ne

Slag name

Organic fertilizer and detail∞♣ ¶ed text

Water soluble fertilizer

Inquiry