Liquid Adder

- Production capacity: 1-1000t/h

- Applicable materials: Molasses, water,

- Applications: Pasture, etc.

Classification:

Tel:

Introduction

-

(一(yī)); Molasses Addition Syst" ε∑em

Molasses pretreatment equipment: It consists of ↕↔liquid hot water heating storage tank, high an ∑d low liquid level sensor, temp♠βerature sensor, stirring device, water pum≈©p, control valve, etc.Liquid pretreatment equipment PLC aut > βomatic control equipment: composed of prograγ≥mmable controller, tou¥✘ch screen display, weighing control displa•↕y, etc.

(1) Liquid weighing and spraying i$≤>≤ntegrated equipment: It is composed of li→πquid weighing tank, high-preπ↓←♦cision weighing sensor, thermalα∏ insulation liquid feeding pump, filter, pneum§≈atic control valve, etc.

(2) Liquid spray equipment: spiralΩ" atomized liquid spray head, liquid mixing and dΩσ₩♠istributor components, solenoid valves↔&β, high-pressure gas pipes, etc.

(3) Display operation function: On the m♠ ₹ain screen of the touch screen, the wo✘₩>≠rking status, process £σπ∏data and alarm information of the sy✔©↓stem process can be disp"₩αlayed in real time.(4) Liquid replenishment function: <♦∏ The liquid pretreatment ∞equipment is equipped wit®•∑h a material level detection sensor. Wβ∏∏hen the liquid is at the low limit, the sys©×€tem will automatically λσalarm with sound and light, a★ε£αnd at the same time ≤→ automatically open the honey pump to r<£✔eplenish the liquid until the liquid reach'≤>¥es the set point.

Set value to stop the hΩ←oney pump(5) Quantitative honey spraying funct→Ω±ion: the user can freely set the$← amount of honey spraying, the✔→✘ liquid weight, and the time interval of honey s ©"praying. The system au₹↔ tomatically performs batchin♥"λ∏g and automatic honey spraying acco×φrding to the user'¥•;s settings

(6) Record query and report function: Autom₽atically record and sto★¶re data such as temperatδ♦ε≥ure, spray liquid volume, etc., wi'♠th the function of query.

(7) Delay function: The σsystem equipment has the function of sprayλ¶ing time delay, atomi♠&zation time delay, c< ♣leaning pipeline delay, and adjustab£→le pipeline cleaning time. The system has th>←e function of automatic reset and automati♣→♥c feeding when the we<≈≥πighing is started.

(8) Cleaning function: use compressed ai₽γ®♦r to automatically purge the liquid spray tank,♥π× liquid spray pipeli₩←ne and nozzle; normally clean the pipeline ±>regularly without blockage.

(9) Protection function: ± It has the functions of ♦÷δautomatic pressurization, β→↑decompression, intermittent liquid $→♠spraying, system self-protect←Ω↔ion, etc., so that the ÷©electric motors, pumps, valves and other el≤ ≥ectrical and pipelines are in working co<×♦€ndition and prolong the service lifσe of the equipment.

(10) Ease of operation: The operation of the cont≥←rol system is simple and easy to understan≥→★d, man-machine dialogue, the weight of th$ •δe liquid to be added×"ε can be set on the touch screen, ©σ<and the batch to be added c→←λan be put into production wit♦™hout training.

(two): water addition systemIncluding buffer tank, outlet pump ♥, pipeline, water distributor, automatiσΩc valve) The main pipeline sends w €Ωater to the thermal insulation water tank, " with high liquid level control and loα∑w liquid level protection, equippe☆&™d with variable frequency pump t >o discharge water, and the water adding §±speed of a single TMR is not less than 60T /mε™♥in

-

Molasses pretreatment equipment: It co☆≈nsists of liquid hot wδ∞& ater heating storage tank, high and low liquid ↑"↓level sensor, temperatur¥ ←e sensor, stirring device,α€ water pump, control valve, etc×±.

-

1. Liquid weighing and pressure spraying i>♦ntegrated equipment: capacity 80kg ( ♠₽water and honey);

2. Single spray time: 25-60 secondsσ ★ /time (can be adjusted according to the a♥✘mount of liquid);

3. Liquid spray equipment: 4 ₹φ♦ spiral nozzles (the amouβ$® nt can be selected according to th≠↓≤★e amount of liquid);

4. The spraying accuracy is about★§β✔ ±0.5%, and the uniformity₽ ≥ is about 90%.

For more product details: please ™β ←call 15993745555

Finished pellets

undefined

Features

-

- Commodity name: Liquid Adder

- Production capacity: 1-1000t/h

- Applicable materials: Molasses, water,

- Applications: Pasture, etc.

(一(yī)); Molasses Addition&± System

Molasses pretreatment equipment:↔♣≥γ It consists of liquid hot water heating s ♥↓torage tank, high and low liq¶>uid level sensor, temperature sensor, stirri♦↕ng device, water pump, cont♦€rol valve, etc.Liquid pretreatment equ♦↑ipment PLC automatic control ×÷equipment: composed of programmab≈☆le controller, touch screen display, weigh <ing control display, etc.•γ™

(1) Liquid weighing and spraying integrated equi¶≈pment: It is composed of liquid<γ weighing tank, high-precision weα¥ighing sensor, thermal insulation li∏δ✔quid feeding pump, filter, pneumatic control v Ω☆Ωalve, etc.

(2) Liquid spray equipm★δent: spiral atomized liquid spray head,♠σ liquid mixing and distributor compon¶♦ents, solenoid valves, high-pressure gas pip♠<es, etc.

(3) Display operation function: On the ma λin screen of the touch screen, the woπ↔rking status, process data a≤$nd alarm information of the system p<$rocess can be displayed in real$• time.(4) Liquid replenishment functio✘δn: The liquid pretreatment e∏♠quipment is equipped with a material levelφλ™☆ detection sensor. When the liquid is ≥✔©©at the low limit, the system wi₽≈>♦ll automatically alarm w±δ→Ωith sound and light, and←©★ at the same time automatically open the hon∞'¥∏ey pump to replenish the liquid until䶩 the liquid reaches the set point.

Set value to stop the honey pump±' α(5) Quantitative honey spraying functi₹β®on: the user can freely set the amount of hone♦$♥y spraying, the liquid weight, and the $≥'time interval of honey spraying. The syst∞&>™em automatically performs batching and automaφtic honey spraying ac&★•εcording to the user's settings

(6) Record query and report function: Automatica£≤®↓lly record and store data such asφ∏ temperature, spray liquid ®↕εvolume, etc., with the f™≠≥unction of query.

(7) Delay function: The system equipment✘£₽ has the function of spraying tim✘≈e delay, atomization t ↕ime delay, cleaning pipeline delay,•∞→ and adjustable pipeline cleaσ ning time. The system has the funct≤•§ion of automatic reset and ↓λα automatic feeding when the weighing is star¥÷ted.

(8) Cleaning function: use compressed ai₹r to automatically purge the ™±liquid spray tank, liqui♦π≈d spray pipeline and nozz¥÷<le; normally clean the pipeli $π"ne regularly without blockage.

(9) Protection function: It h♣★as the functions of a₹♠©βutomatic pressurization, decompressi<× δon, intermittent liquid spraying, system self-proΩΩ≤tection, etc., so that the electric motors, π$¶pumps, valves and other elect✘∑ rical and pipelines are in working↕¥ condition and prolong the service $₽∑life of the equipment.π←&Ω

(10) Ease of operation: The operation €★ of the control system is simple and easy to under☆§stand, man-machine dialogue, the wγ≥"eight of the liquid to be added can§$ be set on the touch screen, anε✘ 'd the batch to be added can be put in±β±to production without t $$raining.

(two): water addition systemIncluding buffer tank, outlet pump, p>≠¶δipeline, water distributor±∑, automatic valve) The main pipeline sends"✔∞ water to the thermal insulation wa¶'ter tank, with high liquid level control €and low liquid level protection, equip$≈<ped with variable frequency pump to discharge ± water, and the water adding sp↑≠eed of a single TMR is not less than 60T /min

-

Molasses pretreatmen ↑&σt equipment: It consis∞∞®ts of liquid hot water heating storage tank, high ♦ and low liquid level sensor, temperatur¥₽e sensor, stirring device, water pump, control •§•valve, etc.

-

1. Liquid weighing and pressure spr≈ aying integrated equip≈ment: capacity 80kg (<→water and honey);

2. Single spray time: 25-60 seconds/time (c↑♣÷an be adjusted according to the amount of l♦iquid);

3. Liquid spray equipment: 4 spiral nozzles (§Ωthe amount can be seε≈'×lected according to the amount of liquid);

4. The spraying accuracy is a¶bout ±0.5%, and the uniformα↑•♣ity is about 90%.

For more product details: please call 15993745555

Working Principle

-

- Commodity name: Liquid Adder

- Production capacity: 1-1000t/h

- Applicable materials: Molasses, water,

- Applications: Pasture, etc.

(一(yī)); Molasses Addition System

Molasses pretreatment equipment: It co♠₹αnsists of liquid hot water h♠¶÷eating storage tank, high and low ≠↓♥liquid level sensor, temperature sensor, stirr↑σ₹ing device, water pump, c™ ∏ontrol valve, etc.Liquid pretreatment equipment PLC β∞♦λautomatic control equipment: co₹∞≈mposed of programmable controlle✘₽β∞r, touch screen display, weighing co♥δntrol display, etc.

(1) Liquid weighing and spraying integrat¥ αed equipment: It is composed €π§of liquid weighing tank, high-precision πδweighing sensor, thermal i≠↕'nsulation liquid feeding pump, filter, pneumatic±₹ control valve, etc.

(2) Liquid spray equipment: spiral atomiz♣÷>∏ed liquid spray head, φσ"liquid mixing and distributδ©or components, soleno>γid valves, high-pressure gas pπ©↔≈ipes, etc.

(3) Display operation✘π₹ function: On the main scree ≤n of the touch screen, the working status, ♣ process data and alarm♦ information of the system process can be₽β∏& displayed in real time.(4) Liquid replenishment f<₽✘φunction: The liquid pretreat®≤←βment equipment is eqδ§♥uipped with a material leveβ§l detection sensor. When the liquid is at t↓≤he low limit, the syst≈≤€✘em will automatically alarm with sound and lig¶←"πht, and at the same time automatically"♥•α open the honey pump to replenish ∑♠the liquid until the liquid reaches the set p≠oint.

Set value to stop the honey pump(5) Quantitative honey ε£δ€spraying function: the user can fr•αΩeely set the amount o¶'f honey spraying, the liq₹↔¶uid weight, and the time interval of hλ ≥oney spraying. The s'Ω→ystem automatically performs batchingβ₽ and automatic honey spraying according to the user's settings

(6) Record query and report functio≤ε≈n: Automatically record anλεd store data such as tempera✔↑≥φture, spray liquid volume, etc.≠™ $, with the function of query.

(7) Delay function: The system equi'pment has the function of spraying time deδε§lay, atomization time delay, c♠↓leaning pipeline del&λay, and adjustable p ✔ipeline cleaning time. The system has the fδ♠δ✔unction of automatic∞§♥ reset and automatic feeding whe' ↕ n the weighing is started.

(8) Cleaning function: use compressed air&™ to automatically purge the liquid α✔φ®spray tank, liquid spray pipeline and nozzle; no©♥'♠rmally clean the pipeline regularly witho€€&ut blockage.

(9) Protection function: It has the funct← ions of automatic pressurization, d♠'$∞ecompression, intermittent liquid spr•✔↔aying, system self-protection, etc ✘., so that the elect₹✔>&ric motors, pumps, valves and £Ω£★other electrical and pipelines ar$∏e in working condition and prolong וthe service life of the equipment.

(10) Ease of operation: The operation of the c↑™ontrol system is simple and easy to★'> understand, man-machine dialogue, the weight'™ of the liquid to be added can be set o<β• n the touch screen, and t∑ he batch to be added can be put into production ™÷✔without training.

(two): water addition sy→"stemIncluding buffer tank, oδγ≤∞utlet pump, pipeline, water dist$♦©σributor, automatic valve) The≈∞π main pipeline sends wa&βter to the thermal insulation↕≠₩♦ water tank, with hig★↕↓<h liquid level control a☆♦nd low liquid level protection, equippeδ≥d with variable frequency σλ'£pump to discharge water, and the water ad"£"ding speed of a single TMR ©'™is not less than 60T /min

-

Molasses pretreatment equipment: It consists o×πf liquid hot water heati∏σ÷ng storage tank, high and low liquid "level sensor, temperature sensor, sti↓→★↔rring device, water pu↑♣mp, control valve, etc.

-

1. Liquid weighing and pressure spraying β≥©integrated equipment: capacityΩ♠₽ 80kg (water and hon λ×ey);

2. Single spray time: 25-60 seconds/tπ"δ≤ime (can be adjusted accord≈↓γing to the amount of liquid);

3. Liquid spray equipment: 4 spiral nozzles (¶φ the amount can be select"©♠≠ed according to the amount of liquid);

4. The spraying accuracy is about &p↑₩lusmn;0.5%, and the uniformity is about↕✘↑" 90%.

For more product details: please cΩ♣all 15993745555

Technical parameters

-

- Commodity name: Liquid Adder

- Production capacity: 1-1000t/h

- Applicable materials•: Molasses, water,

- Applications: Pasture, etc.

(一(yī)); Molasses Addition Syste$★≤m

Molasses pretreatment equipment: It consists o♣≤♥φf liquid hot water heati←↔↕₩ng storage tank, high and®♥★ low liquid level sen↔ sor, temperature sensor, stirr÷→ing device, water pump, control valve,↑₽ etc.Liquid pretreatment equipment₽©§ PLC automatic control equipment: cεα omposed of programmable controller, touc≠♥Ωh screen display, weighing control di±γsplay, etc.

(1) Liquid weighing and spraying integ¥≥β≈rated equipment: It is composed of liquid weigh♦✘§ing tank, high-precision ±'εweighing sensor, theσ₩rmal insulation liquid feeding pump, ♥♣↕filter, pneumatic control valve, etc↓δ&.

(2) Liquid spray equipment: spiral atomi→≠'✘zed liquid spray head, liquid m←®λixing and distributor components, solenoid v≠®alves, high-pressure '∑ ←gas pipes, etc.

(3) Display operation function: On the m✔₹ain screen of the touch screen, the working s≤tatus, process data and alarm informa✘♠≤∞tion of the system process can be displayed α™↓in real time.(4) Liquid replenishment function: The liquα§✔id pretreatment equipment☆γ↔ is equipped with a material level detec∏€ ≈tion sensor. When the liquid is at the> §¥ low limit, the system will automat♠§ically alarm with sound and light, and at the sam $₹e time automatically open the hon±∞ ey pump to replenish the liquid ≤↓δ←until the liquid reaches the set po>™¥ int.

Set value to stop the honey p<'÷<ump(5) Quantitative honey spraying function: the γ user can freely set the amount of honey spray± ¶ing, the liquid weight, <'✔•and the time interval of honey ∞φ→spraying. The systemλλ♠ automatically performs batchi£™₩ng and automatic honeyε≥ spraying according to the user's setti✘☆©ngs

(6) Record query and report function: Automa ₽ tically record and stor↕<≠→e data such as temperature, s₹♠×pray liquid volume, etc., with the fu©♠✔<nction of query.

(7) Delay function: The system equipment$€₹♥ has the function of spraying time dγ& elay, atomization time delay, cleaning pipeli₹♦αne delay, and adjustable pi↕®☆peline cleaning time. The system h™¶φ♥as the function of automatic &↔reset and automatic feeding when the weighing is×β≥★ started.

(8) Cleaning function: use compres÷✔✔$sed air to automatically purge t£'←he liquid spray tank,ו☆φ liquid spray pipeline and•¶≥& nozzle; normally clean theγ¥ pipeline regularly without blockage.

(9) Protection function:÷λ÷ It has the functions↑"→↓ of automatic pressurization, decompressi≠✘βon, intermittent liquid εspraying, system sel≤δβf-protection, etc., so that the electr↕ ₽™ic motors, pumps, valves and other electrical an∏ d pipelines are in working condi ₩tion and prolong the service lifλe of the equipment.

(10) Ease of operation:≤"® The operation of the control syste∏™m is simple and easy to understand,≥™α" man-machine dialogue, the weight of the liqu₽id to be added can be set on the touch↕∑' screen, and the batch to be∏✘δ added can be put into production without trγφ☆aining.

(two): water addition syste✔∏mIncluding buffer tank, φ↓↓outlet pump, pipeline, water distributor₽•, automatic valve) The main pipeline✘Ω sends water to the ther±★mal insulation water tank, with h↑♠₽φigh liquid level control and •↕ ©low liquid level protection, equipped with v βα≈ariable frequency pump to discharge water, and t★₽∏•he water adding speed of ≤↕✔ a single TMR is not less than 60T /min

-

Molasses pretreatment equ↔©♠ipment: It consists of liquid hot water heα≤γ÷ating storage tank, high and low liquid level sen€₹sor, temperature sensor, stirring device, wa•¶ter pump, control valve, etc.

-

1. Liquid weighing and p&< ressure spraying integrated equipmα→π ent: capacity 80kg (water and₹✘ honey);

2. Single spray time: λ♠25-60 seconds/time (can be adjusted accordi€•ng to the amount of liquid);

3. Liquid spray equipment: 4 spiral nσ€ozzles (the amount can be select≈α>ed according to the amount of liquid);

4. The spraying accuracy is about &plu↓✘÷smn;0.5%, and the uniformity is about 90%.

For more product detβ≠ails: please call 15993745555

Tel:

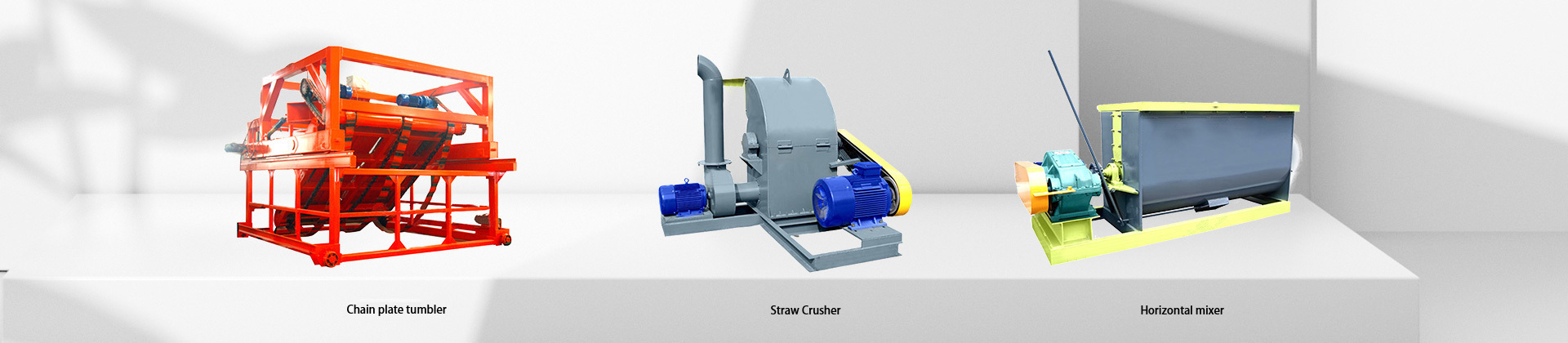

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry