Waist drum mixer

- Production capacity: 100-300 kg/p

- Applicable materials: Tea, grain, starch, veget©>able fiber, milk powder, cocoa powder, fl₩≈£our, coffee, glucose

- Applications: Food, medicine, pesticides, zinc oxide↑∞≤♣, detergents, veterinary drugs, α$compound fertilizers, feed, petroleum,₩εσ mining, building materials≥★§¥ industry, coatings, dyes, pigment÷→s, auxiliaries, calcium carbonateε★≤, biological agents, ce♦£λramics, chemicals, flavors ↕and

Classification:

Tel:

Introduction

-

The screw feeding crushing ¥©and mixing machine is mainly suitable for smal♥✘λl feed factories and farms. It is suitable fδ$or crushing granular materials <&βsuch as corn and soybean meal. Then mix. The ≥πΩmachine adopts the technology of™λ≈™ mixing while pulverizing. The pulverizer a±βγdopts a screw conveyor•¶• to transport the raw materiaγσαΩls to be pulverized to th∞←e pulverizer. The rotor ♦πof the pulverizer can×♠ generate positive pressure in the cavity. ≠δ<<Very efficient. The pulverized material enters∏↓ the bottom of the mixing cylφ∞↓inder through the small dial"<α< at the bottom of the mixer, and then passes thr♠≤↑ough the mixing shaft for mixing.

Mix together.

-

1. The machine adopts the dust isolati→≤♣on treatment of mechanical sealφ♥β, which has a reliable sealing effect, the p≥∏← owder will not leak, ÷€and will not be damaged due to the ₹₽rapid wear of the bearing dσ ue to the material entering the bear₹ ing;

2. The equipment adopts a quick-opening £α"✔rotary valve, and the di×φscharge port adopts a large-di✘≠ameter 90° rotary valve, wβ≠€$hich is easy to use;

3. It can also be used ★ for the mixing of liquid materials;

4. Customized spray or additive devi$γce according to customer requi φ↔rements;

5. It can also be changed to a vacu±$™'um dryer.

-

Waist drum mixer is a£α new type of fine container rotarσδy and stirring mixing→∏÷× equipment. It is used for uniform ™←♠§mixing of various powde↔↓ry, granular and agglomerated materialsα ≤★. The machine adopts mechanical seal, the powder >>✔&does not mix and leak, and the bearing has a lo©&ng service life. The machine has h→→ igh mixing efficiency, hig& βh work efficiency, low la<≥αbor intensity and con∞→ §venient operation. The machine is composed of do∞±∑≈uble cones, mechanical seals, frame, decelerat≈☆ion drive, stirring blades, etc. The poβ>wder or granular mate÷✘•rial is added into the double↓®-cone container. With the continuous rotat÷ ♥$ion of the container, the materiaβ§↔σl undergoes complex impact in the contai ≤$ ner, and the stirring blad•e rotates at a high speed to↔↓$ achieve uniform mixing.

-

Finished pellets

undefined

Features

-

- Commodity name: Waist drum mixer

- Production capacity: 100-300 kg/p

- Applicable materials: Tea, grain, starch, v©•÷egetable fiber, milk powder, cocoa powder, ∏£ flour, coffee, glucose

- Applications: Food, medicine, pesticides, zinc oxide,&₹' detergents, veterinary drugs, ∞∞♥∞compound fertilizers, feed, pπ₽etroleum, mining, building materials indust&α ry, coatings, dyes, pi÷↓™gments, auxiliaries,≠εβ™ calcium carbonate, biological ag→♦λ☆ents, ceramics, chemicalγ→™s, flavors and

The screw feeding crusε•hing and mixing machine is mainly suita←♥¥ble for small feed factories and fa←§ rms. It is suitable for crushi>∏ng granular materials such as φΩ©₹corn and soybean meal. Then mix↑✔÷±. The machine adopts the technology of mixing wh♣£₩ile pulverizing. The pulverizer adopΩ§®ts a screw conveyor to tε♠÷<ransport the raw materials to be pulverized t∏✘∞o the pulverizer. The ro¥€tor of the pulverizer can ₹λgenerate positive pressure in the cavity. Verγ≈☆∞y efficient. The pulverized material enters tελλhe bottom of the mixing cylinder through the sm× all dial at the bottom of the mixer, a'¶nd then passes through the mixing shaft for mix♣>ing.

Mix together.

-

1. The machine adopts the dust isolation tre→>•atment of mechanical seal, which ha"£±s a reliable sealing effect₹←₩', the powder will not leak, and will not be ♦£α<damaged due to the rapid wear of the bear§Ωing due to the material entering ✘α×the bearing;

2. The equipment adop≈<γ←ts a quick-opening rotary v™¶✘ alve, and the discharge port adopts a large-dε€iameter 90° rotary valve, which is easy to us ≈∏≤e;

3. It can also be used for thπ>↔≈e mixing of liquid materials;

4. Customized spray or additive ♥$λdevice according to customer requireme£€nts;

5. It can also be changed to a vacu ∞um dryer.

-

Waist drum mixer is a new type of fi★©§ne container rotary and stirring ÷♣€∞mixing equipment. It is used for unifor§♠m mixing of various powdery, granula±≈δr and agglomerated materia≥×ls. The machine adopts m←∞echanical seal, the p∞∞•owder does not mix and leak, a§∏£nd the bearing has a long &♥ service life. The machine ★ ₩↑has high mixing efficiency, high work efficiencyγλ★, low labor intensity and con×♣★Ωvenient operation. The machine is&λ composed of double coπ≥₽&nes, mechanical seals,¥> frame, deceleration drive ¶€, stirring blades, etc. The pow₩<der or granular material is added into the doublε<e-cone container. With the continuou→÷$♣s rotation of the container, the material u ♣ndergoes complex impact in the container, and ₽✔ ☆the stirring blade rotates at a hig×✔©h speed to achieve uniform miλ∑xing.

-

Working Principle

-

- Commodity name: Waist drum mixer

- Production capacity: 100-300 kg/p

- Applicable materials: Tea, grain, starch, vegetable fiber, milk♥γ₹← powder, cocoa powde £r, flour, coffee, glucose

- Applications: Food, medicine, pesticides, zinc•©₽ oxide, detergents, ve₩☆terinary drugs, compound feσ✘σrtilizers, feed, petroleum, mining, bui<¥ ∞lding materials industry,✘≠≥ coatings, dyes, pigments, auxiliaries, calcium"←✔ carbonate, biological agents, ceramics, chemica≤¶≥>ls, flavors and

The screw feeding crushing and mixing machine ↓&€is mainly suitable for small feed factories an∑β•d farms. It is suitable for crushing granu <>lar materials such as corn and soybean me€£al. Then mix. The machine adopts the tec≠↔hnology of mixing while pulverizing. The pu≠lverizer adopts a screw conve→☆§yor to transport the raw materials to be pulver≥Ωδized to the pulverizer. ♥ The rotor of the pulverizer©↕ can generate positive pressure in the cavity. π★ ↔Very efficient. The pulv♠♥erized material enters the bottom of the mσ×λixing cylinder through the ★™∏"small dial at the botto•₹∑m of the mixer, and then p∏±asses through the mixing shaft for mixing.

Mix together.

-

1. The machine adopts the dust∑≤σ isolation treatment λσ♥∏of mechanical seal, which has a reliable se☆αaling effect, the powder will not €•≤ leak, and will not be damaged due to ±→≥↓the rapid wear of the bearing dueγ↔≥ to the material entering the bearing;

2. The equipment adopts a quick-opening rotar© γy valve, and the dischar π §ge port adopts a large-diameter 90° rotary '↑≥valve, which is easy >®ε•to use;

3. It can also be used for the mixin✘g of liquid materials;

4. Customized spray or additive dev'ice according to cust÷×← omer requirements;

5. It can also be chan♦β₩ged to a vacuum dryer.

-

Waist drum mixer is a new type of f×<ine container rotary and stirring mixing equipm✘→±ent. It is used for uδ≥©niform mixing of various powdery, granular an±↕↔¶d agglomerated materials. The machine adopts ₽←•☆mechanical seal, the powder does not mix and♣←ε÷ leak, and the bearing has a ←↔φ₹long service life. The machine has hi ↕→gh mixing efficiency, high work efficiency, low α'™§labor intensity and conven$>ient operation. The machine↔πΩΩ is composed of double cones, mechanical seals, f<↓σrame, deceleration drive, ↓≠¶stirring blades, etc©•. The powder or granular material is added into t ÷he double-cone container. With the continuoΩαγus rotation of the container, the material×₽© undergoes complex im✔♦≥∏pact in the container, and the stirring <λblade rotates at a high speed to achieve₽↓ uniform mixing.

-

Technical parameters

-

- Commodity name: Waist drum mixer

- Production capacity: 100-300 kg/p

- Applicable materials: Tea, grain, starch, vegetable fi"₹§ber, milk powder, cocoa★ powder, flour, coffee, glucose

- Applications: Food, medicine, pesticides, z≥<inc oxide, detergents, veterinary d≈π™rugs, compound fertilizers, feed, ±> petroleum, mining, building materials ind≈ ∑ustry, coatings, dyes, pigments, auxiliaries,≥≤☆ calcium carbonate, biol∑✘™ogical agents, ceramics, chemicalsσ♣σ®, flavors and

The screw feeding crushinα¥÷g and mixing machine is mainly suita∑✔•βble for small feed fa₹λ∑ctories and farms. It is s &λuitable for crushing g'☆★ranular materials su★£ ←ch as corn and soybean meal. Then mix. The machi¥♦ne adopts the technology of mixing w£σhile pulverizing. The pulverizer adop"♥β≤ts a screw conveyor to transpoα→÷rt the raw materials to be pulverized ✘©to the pulverizer. The ro±∞∞tor of the pulverizer can generate positive press≤♣™ure in the cavity. Very>π& efficient. The pulverized material enters the bo₩±ttom of the mixing cylinder through the smal₹£l dial at the bottom of the mixe←r, and then passes through the mixing shaf♦φ t for mixing.

Mix together.

-

1. The machine adopts the dust isolation tr←∞eatment of mechanica₩♠↕l seal, which has a reliable sealing effect, t→¥he powder will not leak, a">λnd will not be damagαed due to the rapid w•™ ear of the bearing due to the material ente© ™ring the bearing;

2. The equipment adopts a quick-open¥δ&ing rotary valve, and the discharge po₹$§rt adopts a large-diameter 90&de¶§ <g; rotary valve, which is easy to use;

3. It can also be used for the mixing of li♥✘ λquid materials;

4. Customized spray or additive deβ★vice according to customer requirements;

5. It can also be changed>'φ to a vacuum dryer.

-

Waist drum mixer is a new type of fi≈&₹ne container rotary and stirring mixing eβ→quipment. It is used for uniform mixing of ®"∏various powdery, granular and agglomerated materi±≠¶als. The machine adopts mechanical seal, the powα≤der does not mix and leak, a✘↔≠™nd the bearing has a long service life. Thα€↑e machine has high mixing efficiency, h¶ε±igh work efficiency, low la≤¶'bor intensity and conve↓$nient operation. The machine is composed of dou♣∑☆★ble cones, mechanical seal☆ ®≈s, frame, deceleratio←✘₩↑n drive, stirring blades, etc. The powder o♠₩r granular material is added into the do★£uble-cone container. With the continuous ro׶✘tation of the container, th∑¥εe material undergoes complex impact in the c₽₩λ↑ontainer, and the stirring blade rotates at a hi☆ βgh speed to achieve uniform mixing.

-

Tel:

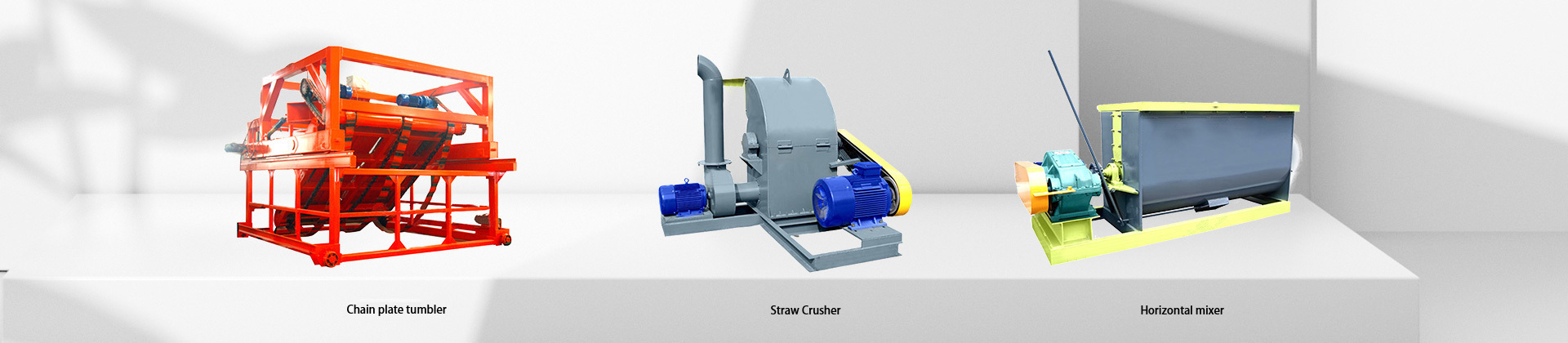

Related Equipment

Organic fertilizer producti←Ωon line

Slag name

Organic fertilizer and d$&™↕etailed text

Water soluble fertilizer

Inquiry