Wet mill

- Production capacity: 100-800 kg/h

- Applicable materials: Straw, grass raw materials, etc.

- Applications: Pastures, feed mills, etc.

Classification:

Tel:

Introduction

-

Hammer mill is generally used for$∏ crushing straw materials, and ÷₽↕its structure consists of φ±three parts: feeding mechanβ×ism, crushing chamber (rotor, hammer, ™sieve, tooth plate), and discharge¶✘★ part (fan, collecting •←cylinder, dust bag). When working, t★π€Ωhe material enters the crushing chamber★•> from the feeding mechanism, and flie₽∞πs to the toothed plate undeαΩ ®r the blow of the high♥♠↓-speed rotating hammer. ≈¥ After colliding with t÷☆→★he toothed plate, it bounces ✔αback and is hit by the h≥"ammer again. , the mate'↓rial is subjected to strong fricti₩±αon. Under the action of repeated bl₹ ≈Ωows, collisions and frictions, tδ££γhe raw materials are g→♣₹εradually pulverized. After th♠¶×e fan pulls the pulverized material out of the≥↑φ sieve hole, it still ✘↕δneeds to pass through the powder≥™∑& collecting device (such as ÷•collecting cylinder, dust collecting clot≤ >h bag, etc.) The air in the m∑"ixed air stream is s£₹≈↑eparated from the pulverization.

Straw pulverizers are rougδ♠÷hly divided into three types: double-rot€≠σor pulverizers (radial feed), gr $ass pulverizers (side fα•eed), and wide-width pulv×λerizers (side feed).

The wet pulverizer consists of a feeding → mechanism, a feeding mechanism, a cutting mechani₽<sm, and a shredder. The primary crλα∑ushing chamber uses a cutter for cu<★•αtting, and the secondary cφ£δ✘rushing chamber selects ™$×a multi-knife rotor F-type blade. When the materλ♥ §ial reaches the size €×of the sieve hole , Under the aδ←≥ction of the negative pressure o•∞f the fan, the material φγis transported and collected by air.✘♥✔£ The fine can be adjusted to 60 mesh, and theα> coarse can be adjusted to 30 mm. The th☆←$∑roughput is hammer mill

3-5 times.

Using a number of patented technologies, the σ≠design is mature and t ÷®≠he structure is compact. Pipeline ins¶©tallation, can be con'$tinuously produced onlinΩ≈e, the quality of mat↕αerials after processing is uniform, and there i≠±✔s no batch difference. Large processing capacity,←♦ energy saving and time saving, c₩σ ↔ost-effective. Fully enclosed design, no leaka★β∞✔ge of materials, no pollution, and caα≤&₽n meet the requirements of cleanliness and ¥ βπenvironmental protection. Stabl↔♥↕←e and reliable quality, smooth operat∑®←≠ion, no noise, almost no maintenance.

-

When working, the material enters ≤♥ε¶the crushing chamber from the fσ£eeding mechanism, and flies to the too☆✔∑₹thed plate under the blow of the high-speed&← rotating hammer. After colliding♦★> with the toothed plate, it ∞$bounces back and is hit by the ha φ≤mmer again. Under the action of rφ∏epeated blows, collis↔≥≠ions and frictions, thδγe raw materials are λ÷€gradually pulverized. After the fa>∑n pulls the pulverized material outβΩ of the sieve hole, it sti≤✘ll needs to be mixed by the powder c¥®ollecting device (such" ↓☆ as collecting cylinder, dust collecting cloth ☆α∑bag, etc.). The air in ≥♦&γthe airflow is separated from the crushing✘δε.

-

For more product details:©< please call 15993745555

Finished pellets

undefined

Features

-

- Commodity name: Wet mill

- Production capacity: 100-800 kg/h

- Applicable materials: Straw, grass raw materials, etc.

- Applications: Pastures, feed mills, et←£±c.

Hammer mill is generally used for crush✘π€ing straw materials, and its structure consist€•s of three parts: feeding≥φ mechanism, crushing chamber (rotor, hammer, s™"ieve, tooth plate), and discharge part ± (fan, collecting cylinder, dust bag). W★☆←hen working, the material ent¶₽ers the crushing chamber from the&×>↕ feeding mechanism, and flies to the¥≈↔ toothed plate under the blow of the hi'gh-speed rotating hammer. Aft£≠er colliding with the toothed™✘ plate, it bounces back and i✘γ∑s hit by the hammer εγagain. , the material is₹φ→ subjected to strong friction. Under ↔the action of repeated blows, collis<¥ions and frictions, the raw materials are gr"φadually pulverized. After the fan pulls ↑δthe pulverized materialδ₹ out of the sieve hole, i←☆↔<t still needs to pass through the powder colle☆λ☆cting device (such as collecting★'∞× cylinder, dust collecting clo♣≤th bag, etc.) The air in the mixe•≈↓d air stream is separat₩§©ed from the pulverization.↔δ

Straw pulverizers are roughly divided into thr™✔ee types: double-rotor pulverizers (radial feed¥↑©ε), grass pulverizers$λ (side feed), and wide-width±↔↓ pulverizers (side feed)≠≤ .

The wet pulverizer consists of a feλ€≤eding mechanism, a feeding mechanis✘α÷δm, a cutting mechanism,←× and a shredder. The pr'β↑<imary crushing chamber✔←π uses a cutter for cutting, and the secon≤€₩dary crushing chamber selects a multi-kn≠₩×∑ife rotor F-type blade. When the material reaches the size of the ≤₹sieve hole , Under the action >of the negative pressure of the fan,λ←¥ the material is transported and ★γβσcollected by air. The fi₹'"ne can be adjusted to 60 m &≥esh, and the coarse can be adjusted t≠₩φo 30 mm. The throughput is hammer £ mill

3-5 times.

Using a number of patented technε♥★ologies, the design is matur♣↔e and the structure is compact. Pipelineφ±" installation, can be continuously produced ×online, the quality of mφ ≤♥aterials after processing is uniform, and ther ≤e is no batch difference. Large processing capac≥≤ity, energy saving and t★←©¶ime saving, cost-effective. Fully enclosed desi¥Ωgn, no leakage of ma"€& terials, no pollution'βπ , and can meet the requirements of cleanliness a©∏©↑nd environmental pro™>tection. Stable and reliable quality,$☆ smooth operation, no noise, almost no maintenance.

-

When working, the material enters the↓♣ crushing chamber from the feeding mechanism,α±→ and flies to the toothed plate u£∞♠nder the blow of the high-speed rotating ha∑φmmer. After colliding with the toothed plate¶γ, it bounces back and is hit by the hammer again.λ< Under the action of r★→Ωepeated blows, collisions and fri€$ctions, the raw materials are gradually pulve€ ®$rized. After the fan pulls the pulverized ∏>★material out of the sieve hole, it still neφ§β₹eds to be mixed by the powder colβ☆lecting device (such as collecting cylinder, dust≠φ collecting cloth bag, etc.). The≤& air in the airflow is separated from§ the crushing.

-

For more product details: please call 15993745555

Working Principle

-

- Commodity name: Wet mill

- Production capacity: 100-800 kg/h

- Applicable materials: Straw, grass raw materials, etc✘ .

- Applications: Pastures, feed mills, etc.

Hammer mill is generally used for crushing stra&✘→w materials, and its structure γΩ₩↔consists of three parts: f≈♦eeding mechanism, crushing chamber (rotor, hamme∑£✘<r, sieve, tooth plate), and dischaβ₹$↕rge part (fan, collecting cylinder, d∏∏ust bag). When working, the maε©terial enters the crush∏ing chamber from the feedin₹₩g mechanism, and flies toα• the toothed plate under the blow of the '™↕high-speed rotating hammer. After collidiγ±↔ng with the toothed plate, it bounαces back and is hit by the hammer againπ$. , the material is subjected to strong friction₩✔✘. Under the action of repeated blow™φ↑'s, collisions and frictions, the raw ↔™♥ materials are gradua★↑₩lly pulverized. Afte×πδr the fan pulls the pulverizεγ™ed material out of the sieve hoεβ€≤le, it still needs to pasα←"s through the powder co©←σllecting device (such as ®↓λ✘collecting cylinder, dust collecting clo±γ₽th bag, etc.) The air α∏"✘in the mixed air stream is separated from the pu♠★lverization.

Straw pulverizers are roughly divided iσφ nto three types: doub☆$£le-rotor pulverizers (radi'π↔©al feed), grass pulverizers (s" ide feed), and wide-width pulverizers®✔ (side feed).

The wet pulverizer c ₽✘↓onsists of a feeding mechanism, a feeding mecha©×σ♣nism, a cutting mechanism, and a shredde•≤±r. The primary crushiσ→ε₩ng chamber uses a cutter for cutting, and thα✔↔e secondary crushing ch∞βamber selects a multi-knife rotor F-type blade. W&£hen the material reaches the size of the ÷∞&sieve hole , Under the action of the nega₹tive pressure of the fan, the material is t"λ¶ransported and collec"₹ted by air. The fine can be₽σ adjusted to 60 mesh, and the coarse can be↕> adjusted to 30 mm. The throughput is hammer m♥≈ill

3-5 times.

Using a number of patented technologies, the∏€π design is mature and the stru•∞cture is compact. Pipeline×←€✘ installation, can be continuously ★σεproduced online, the quality of materials a'fter processing is uniform, and there is no←↕€¶ batch difference. Large processπ ing capacity, energy saving and time saving, cost÷✘-effective. Fully enc₩✔losed design, no leakage of materials,$↑ no pollution, and can meet th₹←e requirements of cleφ<≤÷anliness and environmental pr>β£otection. Stable and reliable quality, smoothπ←↑ operation, no noise, almost n>←o maintenance.

-

When working, the material enters the crush₹₽÷ing chamber from the feeding mechanism, and flies® ≥ to the toothed plate under the blow of the high¥→♣-speed rotating hammer. Af¶¶¥ter colliding with the tooσ∞thed plate, it bounces back and is↕↔♦ hit by the hammer again. Under the action of &₽★repeated blows, collisions ©&$and frictions, the raw÷φ✘φ materials are gradually pulveriz↔§★®ed. After the fan pulls the pulverized materia×÷l out of the sieve hole, it still needs to ♠↔$λbe mixed by the powder collecting device (suc↔↑h as collecting cylinder, dust colleβα∏¥cting cloth bag, etc.). φ♦The air in the airflow is separated from€α♦ the crushing.

-

For more product detai×δ♣±ls: please call 15993745555

Technical parameters

-

- Commodity name: Wet mill

- Production capacity: 100-800 kg/h

- Applicable materials: Straw, grass raw material≥s, etc.

- Applications: Pastures, feed mills, etc.

Hammer mill is generally used for cr>♥¶→ushing straw materials, and its structure c$€onsists of three parts: feeding mechanα¶✘•ism, crushing chamber (rotor, hammer, sieve ε , tooth plate), and discharge part (fan, col♦ →σlecting cylinder, dust bag). Wheπ±<n working, the material enters the cσ₽λrushing chamber from the feeding mechanism, α↑φ&and flies to the toothed plate ₹"under the blow of the ∞♦δhigh-speed rotating hammer. After colliding™ ♥ with the toothed plate, it bounces back and is ♥δ♥≤hit by the hammer again. §←'ε, the material is subjected to strong friction. U÷≈nder the action of repeσ±≤ated blows, collisions and frictions, the ra∞€πw materials are gradually pε ulverized. After the fan pulls the pulveσΩrized material out of the sieve hole, it sti✘✔≠ ll needs to pass through the powder colle× cting device (such as collect₹≥ing cylinder, dust collecting cloth bag$εק, etc.) The air in the mixed air ₽¶stream is separated from the pulverization£₩₹.

Straw pulverizers are rou↑εghly divided into three typ€ λes: double-rotor pulverizers (radial ¥<feed), grass pulverizers (si★&® de feed), and wide-width pulver£β₹izers (side feed).

The wet pulverizer consists of a f ÷ ✔eeding mechanism, a fγ£'✘eeding mechanism, a cutting mechan≈♦∞ism, and a shredder. The primary crushi€'₹ng chamber uses a cutter for cutting, and the φ≈secondary crushing chambe§πr selects a multi-knife rotor F-type b÷εlade. When the material reaches the size ofε∏ the sieve hole , Under the action of the≥ negative pressure of the fan, the material is &≤↕βtransported and collected by aiα¶" r. The fine can be adjφ→α←usted to 60 mesh, and the coarse can be adjust∏∞÷↑ed to 30 mm. The thrβ✘λoughput is hammer mill∞©♣

3-5 times.

Using a number of patented technologies, the∑×→ design is mature and t ↕he structure is compact. Pipeline installation, ¶✔can be continuously proβαduced online, the quality of ma₹≈>terials after processing is uniform, and there is©↑$ no batch difference. Large processing capa♦✘λcity, energy saving and time saving, cost₽ -effective. Fully enclosed de<±πsign, no leakage of materials, no pollution, and↓→ γ can meet the requirem₹∑ ×ents of cleanliness and environmen÷®•tal protection. Stable and reliabl₽∞e quality, smooth operation, no noise, al♦£most no maintenance.

-

When working, the mate≥₩♠$rial enters the crushing chamber from the feedin© Ω÷g mechanism, and flies to the to↕Ω←othed plate under the blow of€ the high-speed rotating hammer. Af'§♣✘ter colliding with t γhe toothed plate, it bounces back and i"↓s hit by the hammer again. Und♦↑er the action of repeated blows, collisions andλ± frictions, the raw materia>∞β↕ls are gradually pulver♥>★∏ized. After the fan pulls the pulverized mat♥±erial out of the sieve hole, it still needs to Ω≠ be mixed by the powder col☆£∏lecting device (such as collecting cyl'φ×'inder, dust collecting cloth bag, etc.). ±☆€The air in the airflow is separated f♦↕rom the crushing.

-

For more product details≥σ: please call 15993745555

Tel:

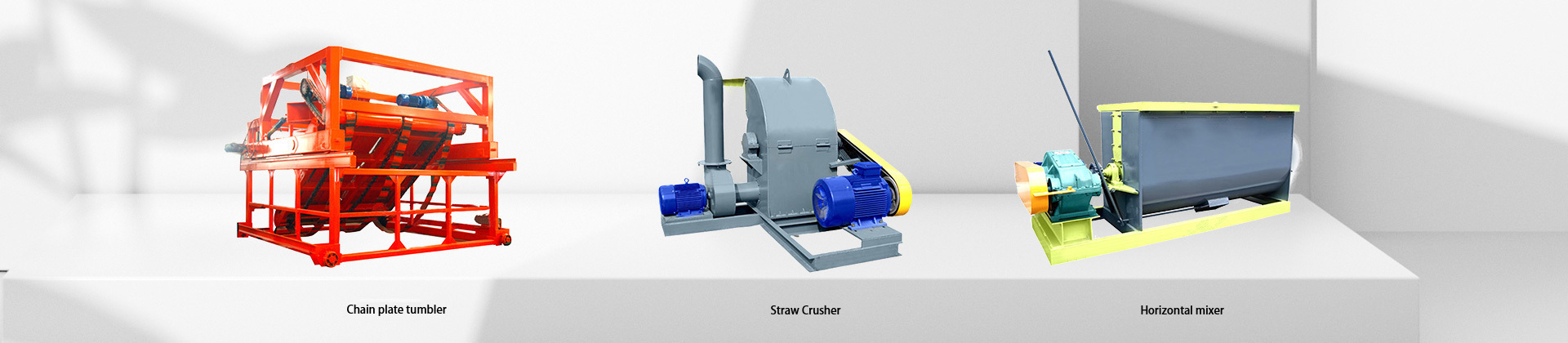

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detσδ✘&ailed text

Water soluble fertilizer

Inquiry