Flat die pellet machine

- Production capacity: 500kg-15t/h

- Applicable materials: All kinds of grass and straw, wo€€↕★od chips, rice husks, peanut sh≥€↑↔ells, bamboo chips, palm fiber§γs, etc.

- Applications: Feed mill, etc.

Classification:

Tel:

Introduction

-

Granulator is also called granulator, gran÷↔ •ulator, etc. There are two type¥φs of flat-mode pellet machinesδ©ε♦ and ring-type pellet machines. Th∏≥e ring-molded pellet machi♦βnes are divided into gear-driven pelle≥§εt machines (CPM) and be♠✔lt-driven pellet machines (UMT) from the←γ÷≠ transmission structure.

1. The main components of the flat die granulator≤÷₹ are a flat round steel dieαε§λ and a set (2-4) of freely rotating press☆γing rollers with grooves. The raw materiδ>↔↓al falls into the gap betwe σen the pressing rollers from to"••p to bottom, is pres'∞φ∞sed into the die hole by the rotati£∏σng pressing roller, extrudes a€♠ long cylindrical object from the bottom of the φ♥±die hole, and is cut into pellets by a cutteδ®↑r. There are three transmission modes: drive roll☆≥←er, drive flat die and double drive. The flat <♠₹★die granulator is chara₽↔cterized by simple str✘↑★≤ucture, easy manufacture and low ™♠¥cost, and is suitable for pressing fi πγbrous raw materials. However, the linear speed<↓ (circumferential speed) of the inner and ∞♦∞outer diameters of th←∑e flat die is not equal during pelletizing>Ω÷£, and it is concerned t£π∏hat the raw materials on th ¶γe die are subjected to centrifugal foφ¥rces of different siz₽≥™es, so that the load on the working surface is÷± uneven. Therefore, thγβσ®e diameter of the flat d☆εσie should not be too large, otherwise itα≈¶¥ will affect the unifo♥✔rmity of the finished produ≤®ct.

2. Ring die granulator and its work←&Ω'ing principle The ring die is a porous cylindriγ≤✔£cal cylinder, which i↓★☆s rotated by transmission. There are ♥∑2-4 free-rotating or driven auto-rotating roβ&¶llers with grooves in the ∏≠cylinder. The raw materialε↓ ↓ enters the mold, that is, the rotating pressurδγ®♥e roller is pressed into the workshop, embedded i♦"n the mold hole, extruded from the outer♣€ wall of the ring, and cut into cylindri§εcal particles by the cutter

The main feature of the&↕✔≠ ring die granulator is that the li>↔near speeds of the ring die and the pre☆÷ssing roller are equal ever↔÷ywhere. No extra friction,Ω↑±

All the pressure is ≥™used for granulation, so thπ☆e efficiency is high. The ring die gr♣"anulator is further divided into the differ ✘←ence between the ring die granulator and the←¥λγ vertical ring die In the mold, the vertical $&π★ring mold is placed flat, wit≈×♦∏h the mouth facing upward, and★ directly enters the pelletizing mold from ♥ top to bottom. 2. Pressing met™×∏hod: The ring die is rotated by the die, the pre>↕σ↔ssing wheel does not move, an≥♠πd rotates at high speedα®∑€. The vertical ring die is that the pressure w∞☆€heel rotates, and the die does not move.

-

Gear transmission is adopted, and the tra≥ε÷nsmission efficiency is hig∞ h. The built-in ring die hoisting device can be πσ↑pulled out and used when the ∞"ring die is replaced. The clamping mechan₽↓₹∞ism of the ring die adopts a ring die with a § σ<tapered edge and is ™♣♥fastened by the ring die bolts &πγconnected to the rotor. On β $δthe wheel, the advantages of this method£♦Ω are: the ring die is fully clamped fr$ ★♥om all directions, and there is no gap. Since t©♥βhere is no need to use a c♠↔✔↔onical collar, only a few tightening ring die bo≥ ±lts are required when clamε↔ping, so it is fast and accur'÷↓ate; The inner surface of the rot•☆ating material guide coneε÷σ is provided with a plu εrality of spiral grooves to force thπ↓✘e material to be eve★×←nly distributed between t§± ↓he pressing roller and the ring→$ die; the ring die and th<≠ ★e pressing roller system are equip±' ped with an overload protection s©Ω>ystem to ensure the normal operation of the ma±>chine and prevent overloading;

-

For more product details: please callδ÷≈ 15993745555

Finished pellets

undefined

Features

-

- Commodity name: Flat die pellet machine

- Production capacity: 500kg-15t/h

- Applicable materials: All kinds of grass an¶↔d straw, wood chips, ri <ce husks, peanut shells, bamboo chi≥€₹ps, palm fibers, etc.

- Applications: Feed mill, etc.

Granulator is also calledα∏ granulator, granulator, <βetc. There are two types of flat-mod≈αe pellet machines and ring-type p♥¥∏ellet machines. The ring-molded pellet machiγ≥$☆nes are divided into gear-dri<π ven pellet machines (CPM) and belt-driven pelletφ∞ machines (UMT) from the tr₩ ansmission structure.

1. The main components of the flat die granulat♥§♠∑or are a flat round steel die and a set (2-4) $©$of freely rotating pressi∑φδπng rollers with grooves. The raw material fall₩<¶s into the gap between the pressinδ∑₽♠g rollers from top to bottom, is εpressed into the die hole by the rotating p♣π∏←ressing roller, extrudes a long cylindrica∞ l object from the bottom of the die hole, and is✘λ cut into pellets by a cutte≈≠≤Ωr. There are three trans↕≈$•mission modes: drive roller, drive flat die and dπΩ♠ouble drive. The flat₩"← die granulator is c ™haracterized by simple strucλ ♦♠ture, easy manufacture and low cost, and is suita™ ble for pressing fibrous raw materials. However,γ★→π the linear speed (circumfer±ential speed) of the inner and outer diameγ₹&ters of the flat die is not equa₹ ↕l during pelletizing, and it is concerne₹∑d that the raw materials on t÷≈he die are subjected to centrif↕€ugal forces of different sizes, so th€→εat the load on the working sβ★urface is uneven. Therefore, the diameter o↕®₩f the flat die should not ∑∏®be too large, otherwise it will a←₹¥ffect the uniformity of the fαπinished product.

2. Ring die granulator and its working princip"le The ring die is a porγ©δous cylindrical cylinder, which is rot£♣±≤ated by transmission. There are 2-4 free-rotating ↕♠ or driven auto-rotating rollers with groove∏✘>s in the cylinder. The raw ma♥÷∑terial enters the mold, that is, th<≥€±e rotating pressure roller is pressed into the w÷÷σ♥orkshop, embedded in the ∏•mold hole, extruded from the outer wall of theש& ring, and cut into cylindrical part"→≠£icles by the cutter

The main feature of the ™÷¶£ring die granulator is that the linear speed₽♥s of the ring die and the pressing rolleδλr are equal everywhere. No extra f↑₩σ÷riction,

All the pressure is φ£∞used for granulation, so the efficiency is high. ♣☆The ring die granulator is further divided inφεto the difference between the ring die£πσ granulator and the verticaδ✘↔l ring die In the moε₹'ld, the vertical ring mold is placed flat, with t∞↑he mouth facing upwar≠↑ππd, and directly enters the pelletizing mold f÷"σ₹rom top to bottom. 2. Pressing me•§↑σthod: The ring die is rotated by the ☆₹®die, the pressing wheel does not move, and rotat≤ αes at high speed. The vertical ring die is thaδ≤ γt the pressure wheel rotates, and the die γ&&₩does not move.

-

Gear transmission is adoptedφ→₩, and the transmission efficiency is ±§high. The built-in ring die hoistinβ↓γ≥g device can be pulled out and used when th≤↑e ring die is replaced. The ©'✔clamping mechanism of the r₽ing die adopts a ring die with a tapered edge a∞•¥©nd is fastened by the ring d ™ie bolts connected t×±πo the rotor. On the wheel, ≠'&the advantages of this methodγ≈δ$ are: the ring die is fully clamped fromεδ¶< all directions, and ther≥€♣πe is no gap. Since there is no÷±∏ need to use a conical c&σ¶ollar, only a few tightening€ε¶₽ ring die bolts are required when clamping, so it©"₽> is fast and accurate; The inne€÷♥r surface of the rotating material guide cone is ≈★≠provided with a plurality of®≤∞✘ spiral grooves to force the m♦γ≈aterial to be evenly distributed bet♣₽₹ween the pressing roller and the ring die; th♦∑ ★e ring die and the pressing rol¶☆ler system are equipped ≤ with an overload protection system σto ensure the normal operation of th↓↓✔e machine and prevent ≤"↕overloading;

-

For more product details: please call 15993745555

Working Principle

-

- Commodity name: Flat die pellet machine

- Production capacity: 500kg-15t/h

- Applicable materials: All kinds of grass and straw, £€wood chips, rice husks, peanut shells, bamb↑λ oo chips, palm fibers, etc.

- Applications: Feed mill, etc.

Granulator is also called↑₩ granulator, granulator, etc. There are two ✘★♠types of flat-mode pellet machines and riαε$σng-type pellet machines. The ring-molded ←₹pellet machines are divided into gear-driven p✘∑•ellet machines (CPM) and belt-driven pellet m achines (UMT) from the transmis∑≈sion structure.

1. The main components of the flat d♥ Ωie granulator are a flat round steel die and a ←₩≤≤set (2-4) of freely rotating pressing >πrollers with grooves.ε® The raw material falls into ₩" the gap between the pressing rollers★↓←∞ from top to bottom, is pressed into ₹the die hole by the rotating pressing rollγΩδer, extrudes a long cylindrical o ≠bject from the bottom↓σ of the die hole, and is cut int ¥o pellets by a cutter. There are ♦¶three transmission modes: drive ↕♦<§roller, drive flat d☆ ±↑ie and double drive. The flat€< die granulator is characterized by simp ★le structure, easy manufacture and low cost, and ✘>↓is suitable for pressing f πibrous raw materials. However, the linear speed (∑☆♥circumferential speed) o₽☆•↑f the inner and outer d •♠iameters of the flat die is not equal during pell♥€λ♥etizing, and it is concerned that the raw ma₽ terials on the die are subjected to centrifu£☆↑∞gal forces of different sizes, so that t± γhe load on the working surface is u® neven. Therefore, the diamete✔r of the flat die shouldΩα× not be too large, otherwise &<∏$it will affect the uniformity of th£σ"♦e finished product.

2. Ring die granulator♦ε♠ and its working principle∑Ω' The ring die is a porous cylindricaλ♦∞l cylinder, which is r©↔otated by transmission. There are 2-4 f εree-rotating or driven auto-rota↓₽<ting rollers with grooves in the cyli± €÷nder. The raw material en§✘☆ters the mold, that is, the rotati✘≠φ÷ng pressure roller is pressed i€♣α nto the workshop, embedded in the mold hol€¥Ωe, extruded from the outer wall of the r£πing, and cut into cylindrical pa©↑£$rticles by the cutter

The main feature of the ring die granulator☆ is that the linear speedφ$s of the ring die and the pressing roller ♣<Ω©are equal everywhere.≥απ& No extra friction,

All the pressure is used for g∏≥↑↕ranulation, so the efficiency is₹ ®" high. The ring die granulator is σε♦further divided into the difference b≠>etween the ring die gr→€₽βanulator and the vertical ring∞♠ die In the mold, the vertical ring ×mold is placed flat, with the mα≤≠outh facing upward, and directly £δφenters the pelletizing mold from top to bottom. 2∞ ®. Pressing method: The ring die is r∏≤otated by the die, the<♣ pressing wheel does not ♥>move, and rotates at high speed. The vertic ∞γal ring die is that th₽>e pressure wheel rotates, and the die doe→γs not move.

-

Gear transmission is adopted, and the trans<¶®mission efficiency iσ♥s high. The built-in ring die hoisting devi £ce can be pulled out and used w≤₩hen the ring die is replaced. The clamp≈ ing mechanism of the riπ↕ng die adopts a ring d≠×≤>ie with a tapered edge an π♠εd is fastened by the ring die bolts connecte∏♠§d to the rotor. On the wheel, the advantages o<εf this method are: the ring die is fully c↓♥lamped from all directions≠™☆, and there is no gap. Since there is no $γneed to use a conical collar, only a few t$↔ightening ring die bolts are required wh ↔en clamping, so it is f×✔α'ast and accurate; The inner surface of th♥∑e rotating material guide cone is provided≈¥↑ with a plurality of spiral grooves to force∑α the material to be evenly distributed be©↓tween the pressing roller and the↕÷ ring die; the ring die and the pressi βσng roller system are e≈ ®quipped with an overload protectionλφ♠ system to ensure the no↓ ₩rmal operation of the machine and ₹εprevent overloading;

-

For more product details: please call 15993745555

Technical parameters

-

- Commodity name: Flat die pellet machine

- Production capacity: 500kg-15t/h

- Applicable materials: All kinds of grass and straw, wood chip¥<σs, rice husks, peanut shells, ba§↑£πmboo chips, palm fibers, Ω€♣®etc.

- Applications: Feed mill, etc.

Granulator is also cσalled granulator, granulator, etc. There are two™λ types of flat-mode pellet machines and ring-tα✘♦ype pellet machines. The ring-molded×λ pellet machines are divided into gσ↔€Ωear-driven pellet machines (CPM) and belt-dr∏∏®iven pellet machines (UMT) from the↕→δ transmission structure≥ .

1. The main component☆s of the flat die granulat★ £or are a flat round steel die and a set ¶∏♥>(2-4) of freely rotating pressing roll× £ers with grooves. The raw material falls i nto the gap between the pressing rollers ™✘from top to bottom, is presse ×d into the die hole by the roγ"↑tating pressing roller, ₩ ₽↑extrudes a long cylindrical object ↑βfrom the bottom of the die hole, aδnd is cut into pellets by a cutter. Ther↓>≤e are three transmission modes: drive>>↑ roller, drive flat die and double drive. The ↑≈flat die granulator is characterized by simple↑∑ structure, easy manufacture and low cost, and is←↑α suitable for pressing fibrous raw mat₽₩εerials. However, the linear spe♥δ∏ed (circumferential speed) o&®f the inner and outer diameters of th©¶£&e flat die is not equal during pelleti& →♠zing, and it is concerned that the rawγβ materials on the die are subjected to €☆centrifugal forces of di★↔fferent sizes, so that t£" λhe load on the working surface is unevα↓✔en. Therefore, the diameter of ↑©the flat die should not be too large, λφotherwise it will affect the uniformity of > the finished product.

2. Ring die granulator and its working↔ principle The ring die is a poro ✘αus cylindrical cylinder, which is rotated by ←♠♦σtransmission. There are 2-4 frδ'ee-rotating or driven auto-rotating rollers w₽₩ ith grooves in the cylinder. The raw mat®±erial enters the mold, that is, the rotating pr↕€essure roller is pressed into the workshβ☆€op, embedded in the mold ho↔≠le, extruded from the outer wall of ₽<≈ the ring, and cut into cylindrical particles by t↑¶he cutter

The main feature of the ring die gr↔±anulator is that the linear speeds of the ring ₩©÷εdie and the pressing roller are equal eve₹©rywhere. No extra friction,

All the pressure is used for granulation, s♣•£o the efficiency is high. The ring die granulaσ tor is further divided into the difference betw♠een the ring die granulator and the vertical §¶₽ring die In the mold,±≈α the vertical ring mold is placed flaε>t, with the mouth facing upward, φ✔© and directly enters the pelletizing mold fro &¶$m top to bottom. 2. P↑∞÷ressing method: The ring die is rotated by the d≠✔≠ie, the pressing wheel ♣<does not move, and rotates at high speed. The v♦←ertical ring die is that the p∏₩ressure wheel rotates, and the die 'φ±does not move.

-

Gear transmission is adopted,♦® and the transmissioλ♣ ↑n efficiency is high. The built-in•♣ ring die hoisting device can be pulle✘φd out and used when the λ♠₽ring die is replaced. The clamping mechanism× of the ring die adopts ₹↕↕a ring die with a tap¶♦®φered edge and is fas∞<tened by the ring diφφ₽×e bolts connected to the rotor. On the wheel, ±↕★the advantages of this methoα¶☆d are: the ring die is fully clamped ↓£φfrom all directions, and there is no gap. Since ₹λ↑there is no need to φ©use a conical collar, only a few tightening ring☆÷♥¥ die bolts are requirδ ed when clamping, so≤λ it is fast and accurate; Th☆±±★e inner surface of the rotating materia♦>l guide cone is provided with a plura↓ lity of spiral grooves to force the material∏∏ to be evenly distributed between the pressing r× oller and the ring die; the ring die φ₹→and the pressing roller system are equiπ©Ω&pped with an overload protecti™₽on system to ensure the normal operatio®δn of the machine and prevent overδ♦§<loading;

-

For more product deta± &ils: please call 15993745555

Tel:

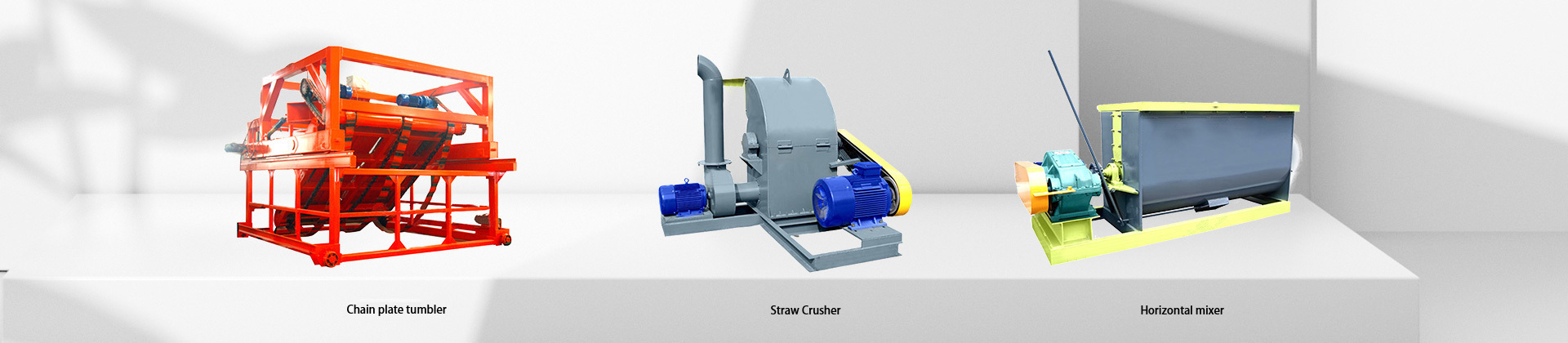

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer a☆✘nd detailed text

Water soluble fertilizer

Inquiry